Base for a high-pressure discharge lamp, and high-pressure discharge lamp

A high-pressure discharge lamp and lamp holder technology, applied in the use of gas discharge lamps, discharge lamps, transformer/inductor components, etc., can solve problems such as wall deformation and achieve the effect of saving fillers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

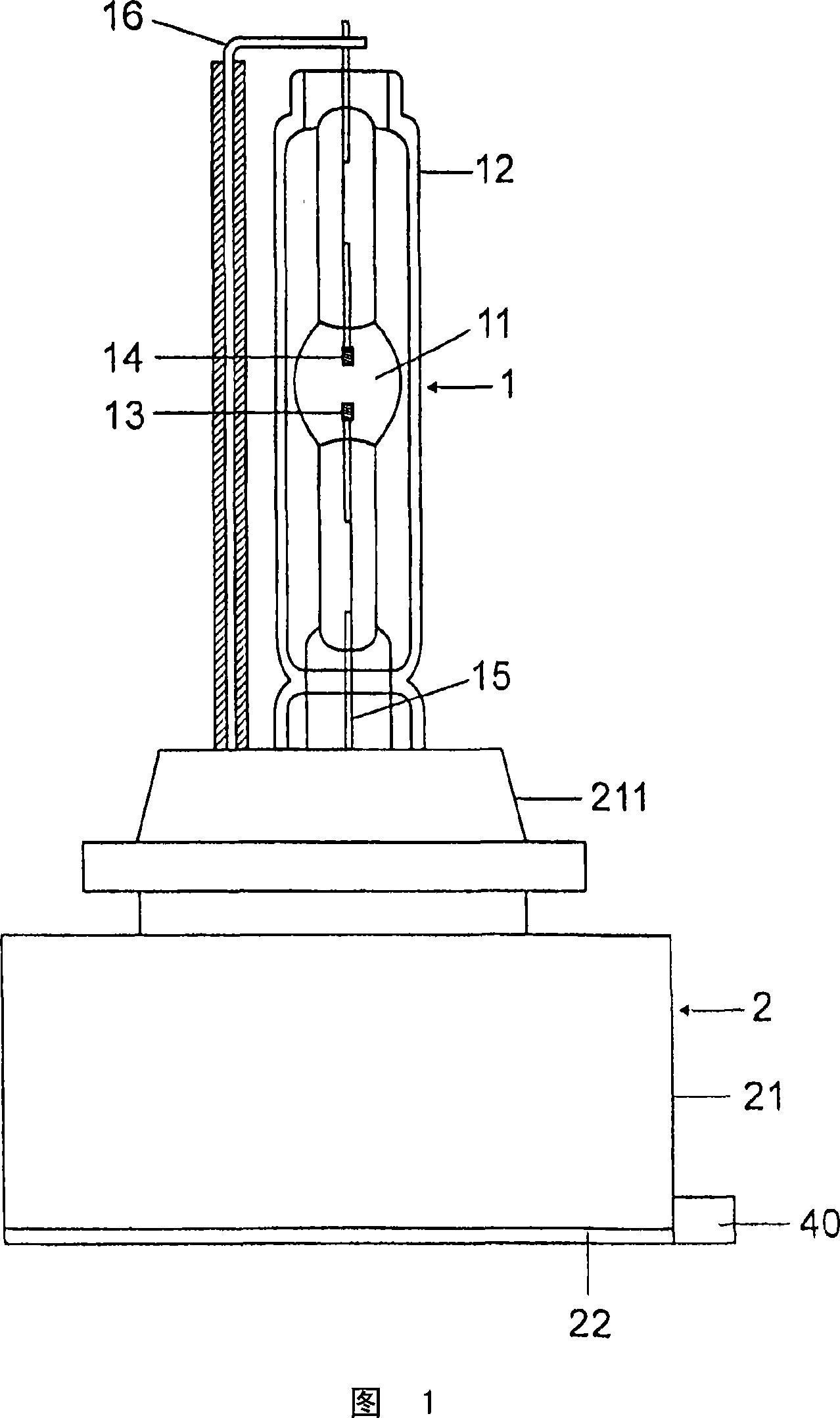

[0017] exist figure 1 In the preferred embodiment of the invention shown in , it concerns a single-sided socket-mounted high-pressure discharge lamp for a motor vehicle headlight. The high-pressure discharge lamp has a discharge vessel 11 enclosed by a glass outer tube 12 , which is made of quartz glass and in which electrodes 13 , 14 are arranged for generating a gas discharge. The electrodes 13, 14 are each connected to a supply lead 15 and 16 leading out of the discharge vessel 11, via which the electrodes are supplied with electricity. The structural unit 1 consisting of the discharge vessel 11 and the outer tube 12 is fastened in a seat 211 of the lampholder 2 . The lampholder 2 has a substantially cuboidal lower part 21 in which the electrical components for the ignition of the high-pressure discharge lamp are accommodated and which is equipped with a connection 40 for the high-pressure discharge lamp.

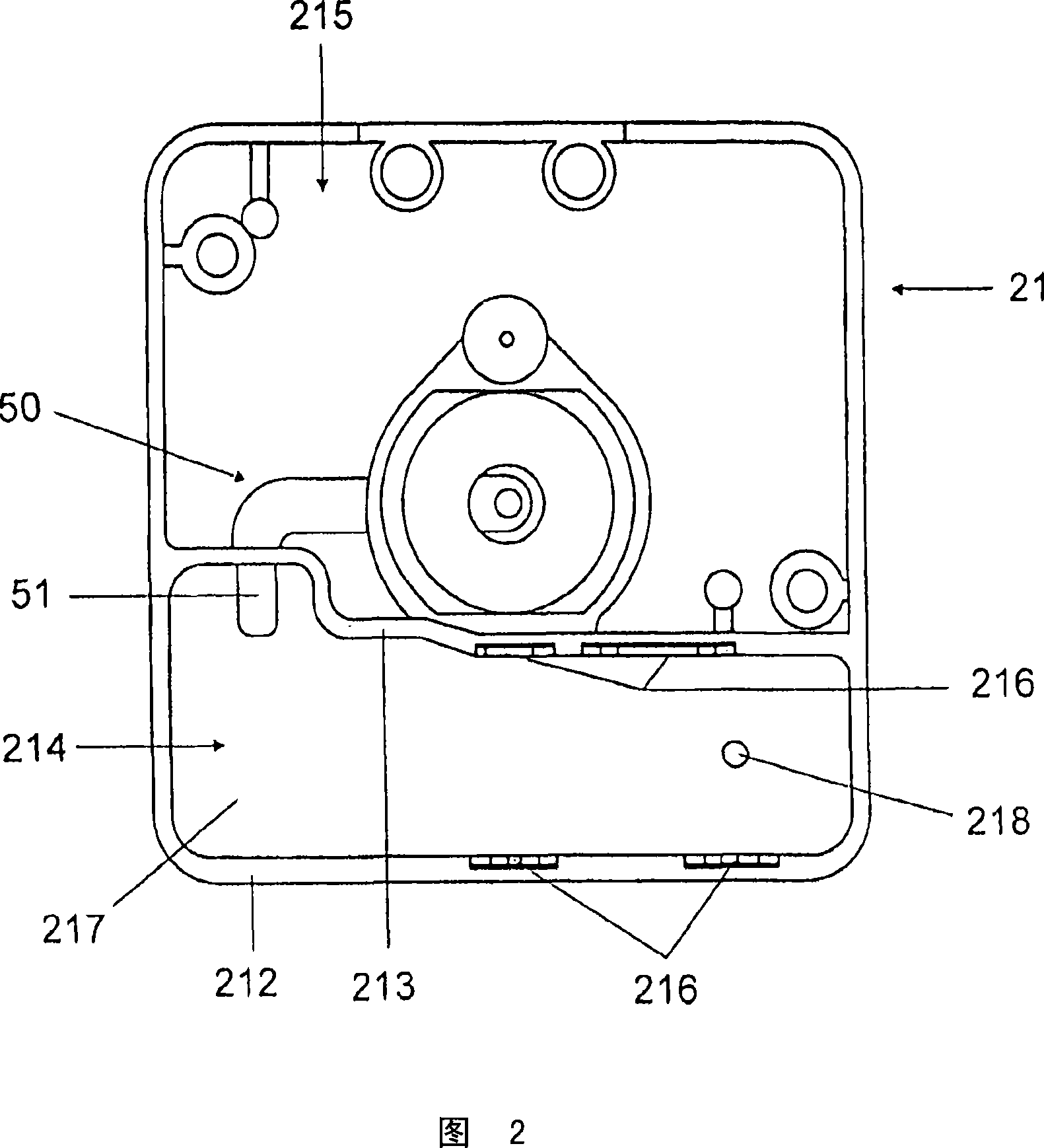

[0018] figure 2 A top view of the side of the lower part 21 fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com