Intelligent pellet distribution control system and method

An intelligent control system and cloth technology, which is applied in the field of intelligent control system for pellet cloth, can solve the problems of production process influence, low reliability, rope entanglement in recycling boxes, etc., to avoid wear and tear, have good compatibility, and overcome left-right asymmetry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

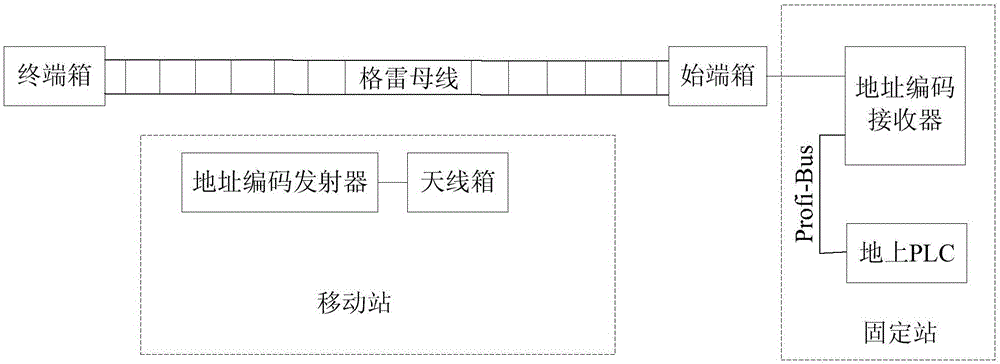

[0034] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

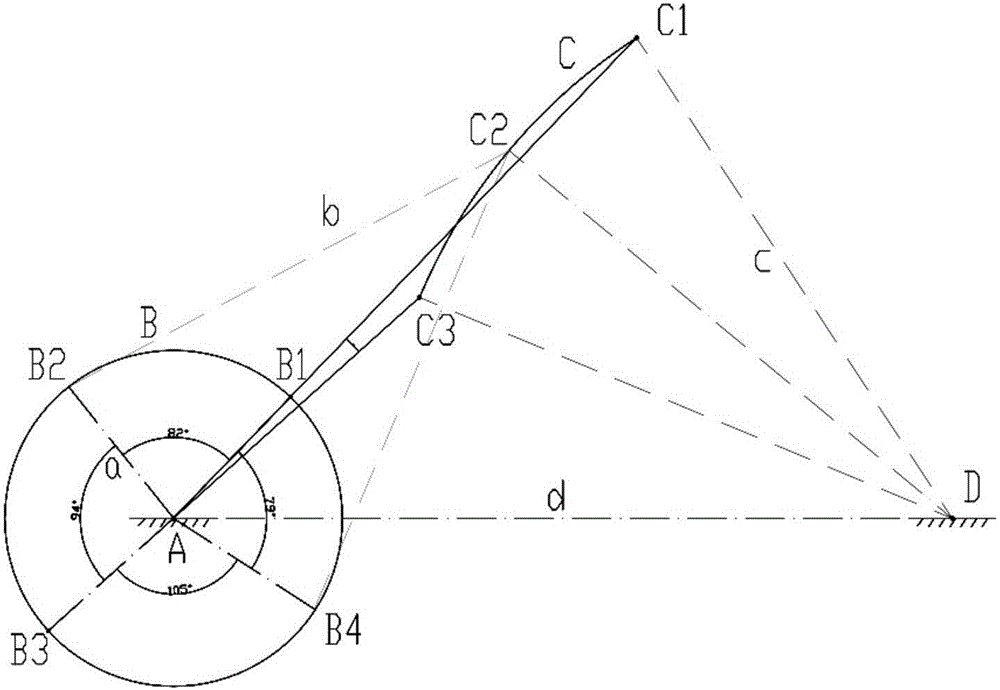

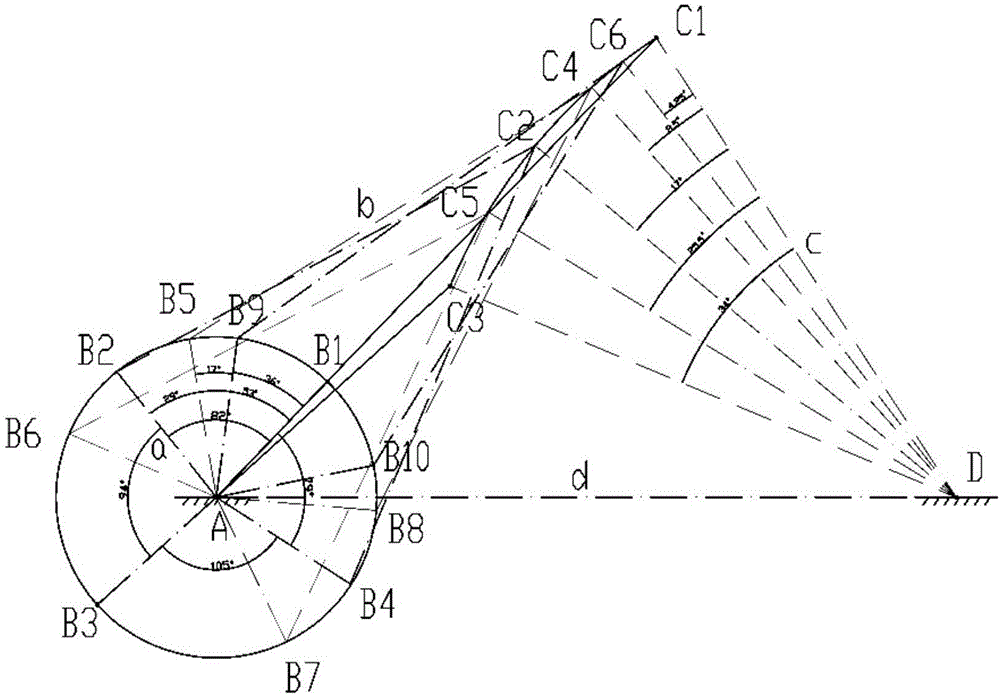

[0035] In the embodiment of the present invention, according to the field actual application (equipment after mechanical adjustment) research data, mechanical design principles, and process production requirements, the left-right asymmetry of the cloth on the grate bed of the chain grate machine, the uneven feeding of the go-back and the edge effect are now aimed at In-depth analysis of the problem:

[0036] 1. Analysis of left-right asymmetry of cloth on chain grate machine grate bed:

[0037] The operation mode of the swing tape machine is that the connecting frame rod (crank) pushes the swing tape machine (rocker) to run through the connecting rod, and continuously feeds the wide tape machine. Assuming that the crank runs at an angular velocity ω, according to the formula:

[0038] T = crank angle / ω (2)

[0039] Table 1

[0040]

[0041]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com