Electric-field-assisted ceramic low temperature rapid sintering device

An electric field assisted, ceramic technology, applied in the direction of furnace control device, electric furnace heating, charge composition/state, etc., can solve the problems of slow heating rate, inconvenient popularization, inconvenient operation, etc., and meet the requirements of reducing energy consumption and equipment, simple structure , Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Adopt the device of the present invention to sinter La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 The specific steps of ceramics are as follows:

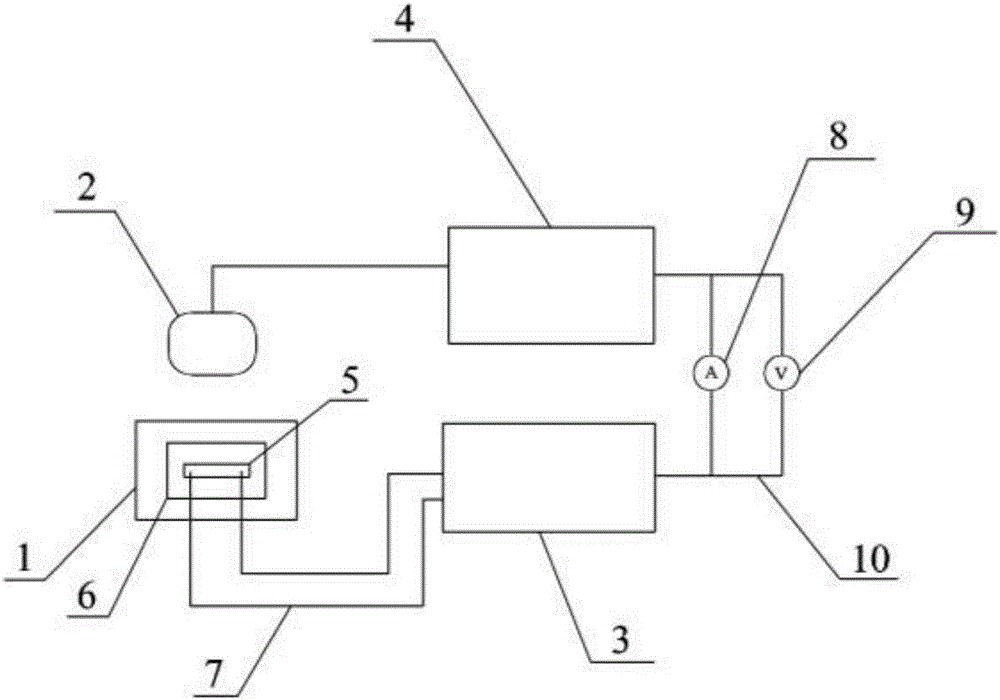

[0032] 1) Connect the two ends of the strip sample 5 to the positive and negative poles of the DC power supply 3 through the superalloy wire 7, and then place the sample 5 flat on the 99% aluminum oxide sheet on the surface of the heating plate 6;

[0033] 2) Set heating stage 1 to 300 o C, start to heat up, after reaching the set temperature, keep warm for 30min, so that the temperature of sample 5 and the surface temperature of heating platform 1 reach equilibrium;

[0034] 3) When the heating platform 1 is keeping warm, set the voltage to 30V and the current to 7.2A;

[0035] 4) Connect the infrared camera 2, voltmeter 9, ammeter 8 and data acquisition device 4 to collect temperature, line shrinkage, voltage and current data in real time;

[0036] 5) After 30 minutes of heat preservation, turn on the DC power supply 3, and after ...

Embodiment 2

[0038] Adopt the device of the present invention to sinter La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3 The specific steps of ceramics are as follows:

[0039] 1) Connect the two ends of the strip sample 5 to the positive and negative poles of the DC power supply 3 through the superalloy wire 7, and then place the sample 5 flat on the 99% aluminum oxide sheet on the surface of the heating plate 6;

[0040] 2) Set heating stage 1 to 200 o C, start to heat up, after reaching the set temperature, keep warm for 30min, so that the temperature of sample 5 and the surface temperature of heating platform 1 reach equilibrium;

[0041] 3) When the heating platform 1 is keeping warm, set the voltage to 60V and the current to 7.2A;

[0042] 4) Connect the infrared camera 2, voltmeter 9, ammeter 8 and data acquisition device 4 to collect temperature, line shrinkage, voltage and current data in real time;

[0043] 5) After 30 minutes of heat preservation, turn on the DC power supply 3, and after ...

Embodiment 3

[0045] Adopt the device of the present invention to sinter Co 2 MnO 4 The specific steps of ceramics are as follows:

[0046] 1) Connect the two ends of the strip sample 5 to the positive and negative poles of the DC power supply 3 through the superalloy wire 7, and then place the sample 5 flat on the 99% aluminum oxide sheet on the surface of the heating plate 6;

[0047] 2) Set heating stage 1 to 300 o C, start to heat up, after reaching the set temperature, keep warm for 30min, so that the temperature of sample 5 and the surface temperature of heating platform 1 reach equilibrium;

[0048] 3) When the heating platform 1 is keeping warm, set the voltage to 50V and the current to 10A;

[0049] 4) Connect the infrared camera 2, voltmeter 9, ammeter 8 and data acquisition device 4 to collect temperature, line shrinkage, voltage and current data in real time;

[0050]5) After 30 minutes of heat preservation, turn on the DC power supply 3, and after the flash burning of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com