Roasting furnace and roasting method

A roasting furnace and roasting technology, applied in the direction of furnace, furnace cooling, furnace charge, etc., can solve the problems of high investment cost of refractory materials, idle refractory materials of furnace body, high energy consumption level of furnace, etc., so as to reduce investment cost, ensure product quality, The effect of reducing the energy consumption level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

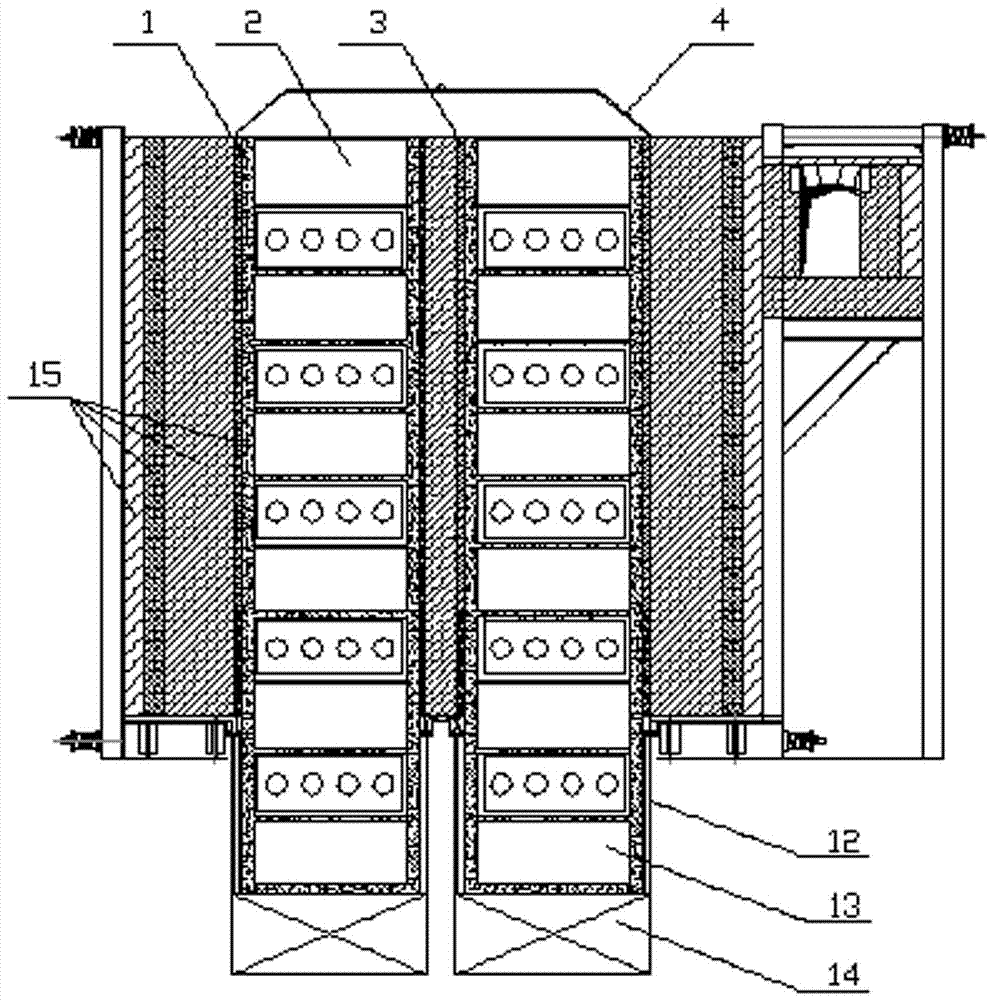

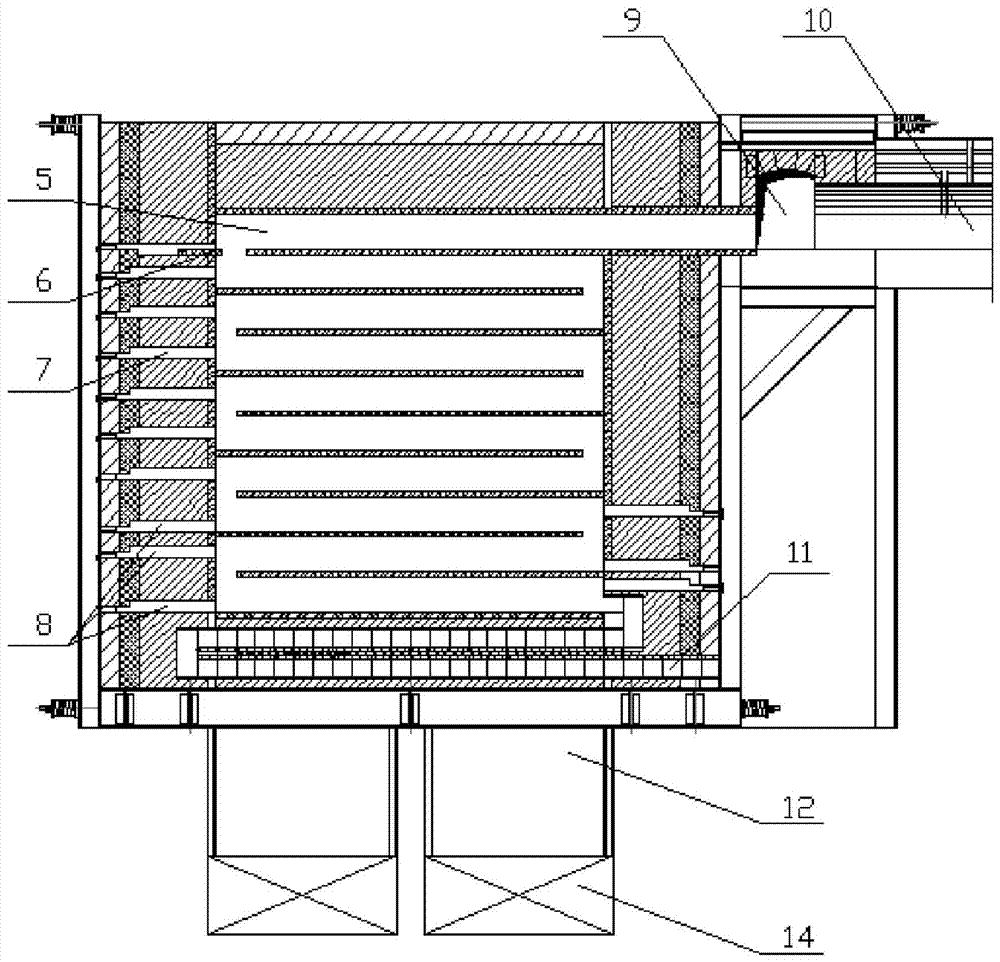

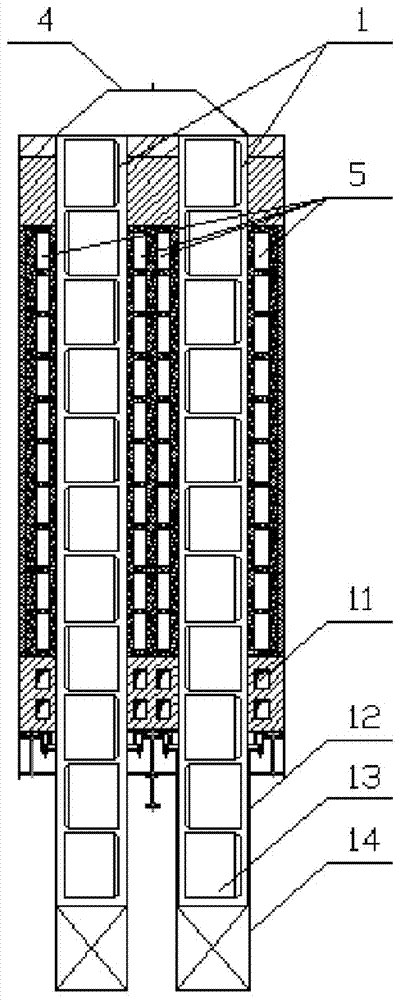

[0040] Such as Figure 1-3 Shown is a roasting furnace of the present invention, which is composed of one unit, with four material boxes 1 and four fire paths 5, and the four material boxes 1 are distributed in the shape of a "field", and each vertical row of two material boxes 1 is arranged on both sides A fire road5. Between the material box 1 and the fire channel 5 is the material box wall. The material box wall is made of refractory bricks. When the refractory bricks are built, there are vertical seams. . A water-cooling jacket 12 is provided at the bottom of the material box, and a block machine 14 is provided below the water-cooling jacket 12 . The water-cooling jacket 12 is a jacket structure, the interlayer is a cooling water flow space, and the interior is a high-temperature roasted product and filler flow space, and the roasted product 13 is cooled to the temperature required for the furnace through the indirect heat transfer method of the cooling water.

[0041] ...

Embodiment 2

[0046]A roasting furnace of the present invention is composed of two units, each unit has four material boxes 1 and four fire paths 5, and the four material boxes 1 are distributed in the shape of a "field", and each vertical row of two material boxes 1 on each side Set up a fire track5. Others are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com