Dazzling china used for decorating bone china

A kind of bone and material technology, applied in the chemical field, can solve the problems of cost consumption, unreachable and consistent color in mass production, etc., and achieve the effect of bright glaze, pure and gorgeous color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, be used for the dazzing porcelain of bone decoration, comprise mud and glaze frit Wherein: mud formula comprises bone carbon 38-43 parts by weight, quartz 5-8 parts, feldspar 16-20 parts , 10-13 parts of raw sand, 7-9 parts of kaolin, 6-8 parts of porcelain powder, 7-9 parts of bentonite;

[0014] The glaze frit formula includes 14-18 parts by weight of feldspar, 28-36 parts of quartz, 2-4 parts of sandstone, 12-15 parts of borax, 12-15 parts of light calcium carbonate, and 2-3 parts of talc , 2 parts of zircon, 4-6 parts of barium carbonate, 3-6 parts of zinc oxide, 2 parts of soda ash, 0-3 parts of lithium carbonate, 63 parts of wrapped scarlet, 1.5 parts of methyl cellulose.

Embodiment 2

[0015] Embodiment 2. Dazzling porcelain for bone decoration, wherein: its technological process includes mud making, grouting or machine press molding made of molds, drying, billet trimming, water replenishment, fine billet inspection, low-temperature biscuit firing, Biscuit inspection, brushing release agent, spraying color, inspection, kiln installation, high temperature biscuit firing, kiln opening, inspection, grinding, cleaning, drying, spraying glaze, glaze firing kiln, glaze firing, glaze opening firing kiln, inspection and selection , into the semi-finished product warehouse, decals, color baking, ground feet, color selection, packaging, into the finished product warehouse;

[0016] Among them: the low-temperature biscuit firing temperature is 1030 degrees, and the firing time is 5 hours; the high-temperature biscuit firing temperature is 1230 degrees, and the firing time is 8-9 hours; the glaze firing temperature is 1130 degrees, and the firing time is 8 hours. ;The c...

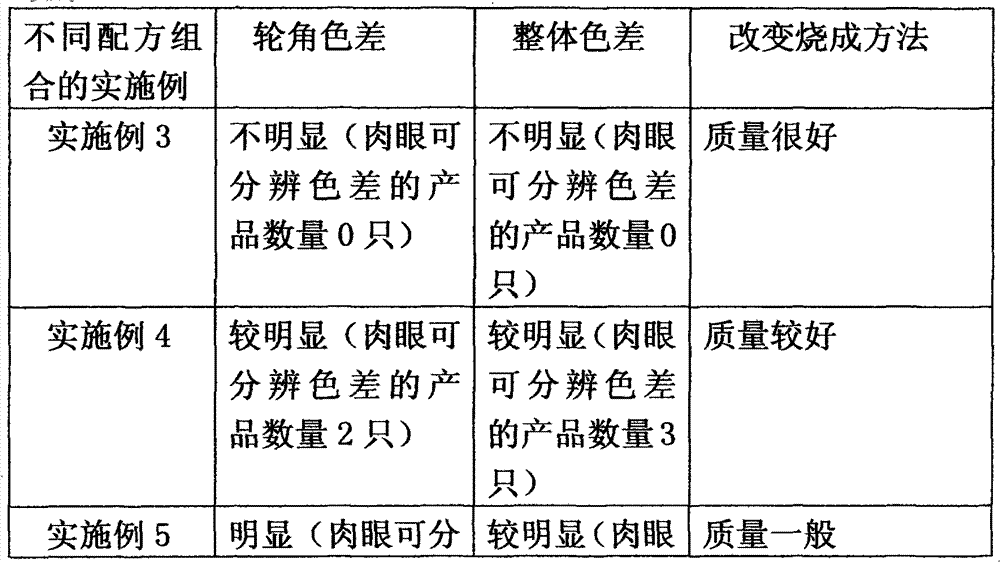

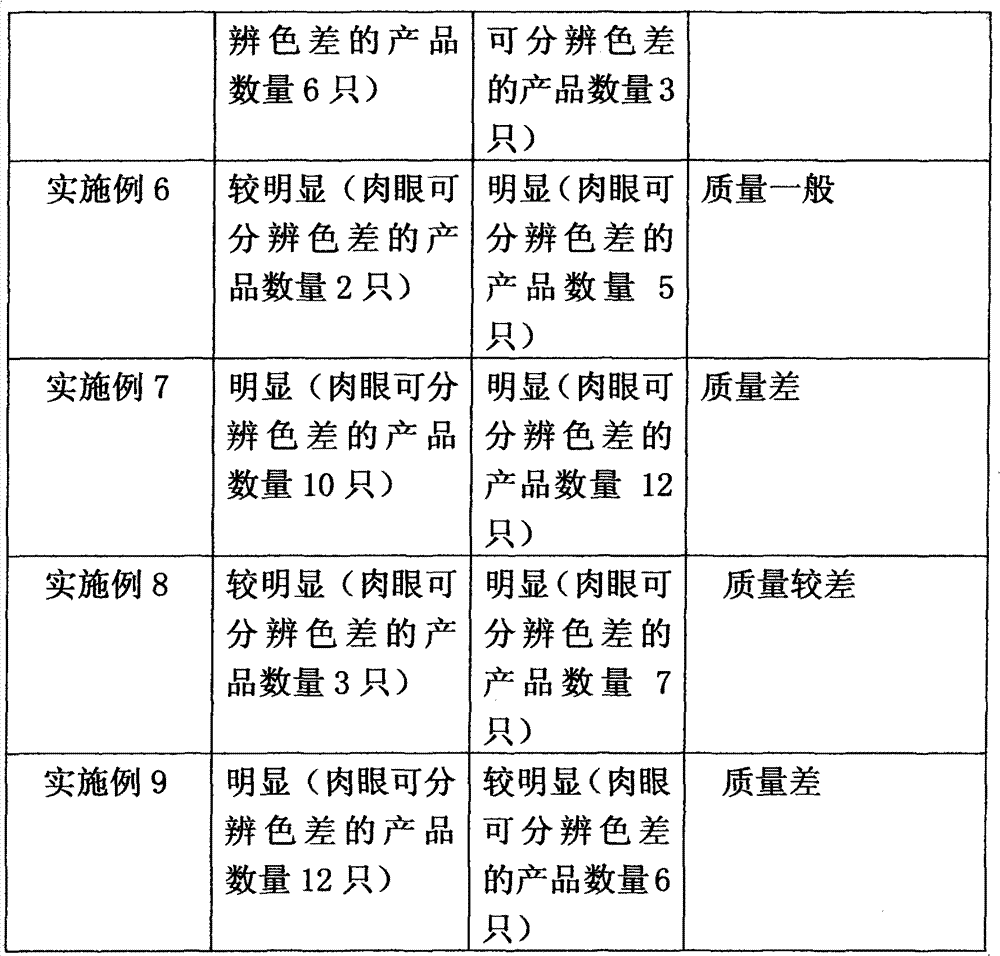

Embodiment 3

[0019] Embodiment 3, dazzling porcelain for bone decoration, wherein: mud formula 1 comprises 43 parts of bone carbon by weight, 5 parts of quartz, 17 parts of feldspar, 10 parts of raw sand, 8 parts of kaolin, and 8 parts of porcelain powder parts, bentonite 9 parts.

[0020] Glaze frit formula 1 includes 16 parts of feldspar, 32 parts of quartz, 3 parts of sandstone, 14 parts of borax, 14 parts of light calcium carbonate, 2 parts of talc, 2 parts of zircon, 6 parts of barium carbonate, and 5 parts of zinc oxide 2 parts, 2 parts of soda ash, 2 parts of lithium carbonate, 63 parts of package scarlet, 1.5 parts of methyl cellulose. All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com