Preparation method of ceramic shadow carving artwork

A technology of artwork and shadow carving, applied in the direction of decorative art, special decorative structure, etc., can solve the problems of thick wall, poor three-dimensional effect, no three-dimensional effect, etc., to achieve low consumption, high market competitiveness, high collection value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

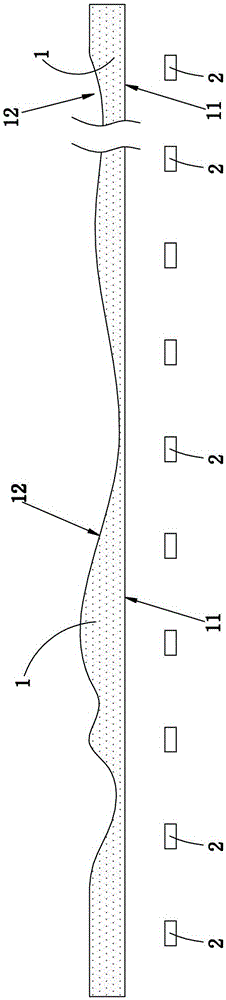

[0027] refer to figure 1 , ceramic shadow sculpture art, including a ceramic body 1, the ceramic body 1 includes an inner surface 11 and an outer surface 12, the outer surface 12 of the ceramic body 1 is uneven to form a regular pattern, and the inside of the ceramic body 1 is provided with a light source. The regular pattern is preferably a character picture or a landscape picture. The regular pattern can fill the entire outer surface 12 of the ceramic body 1, or can be arranged in the middle of the outer surface 12 of the ceramic body 1, and the part other than the engraved part is the outer edge part. The outer edge part mainly plays a supporting role and a decorative role. The thickness of the outer edge part of the ceramic body 1 is 3.0-5.0 mm, preferably 4.0 mm; 3.0mm.

[0028] A method for preparing the above-mentioned ceramic shadow sculpture artwork, characterized in that it comprises the following steps carried out in sequence:

[0029] a. Make map: make map acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com