Matte glaze ink for ceramic jet printing and preparation method thereof

A ceramic inkjet and matte glaze technology, applied in inks, applications, household appliances, etc., can solve the problems of high glazing amount and waste of raw materials, and achieve the effects of good quality stability, low viscosity and uniform particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

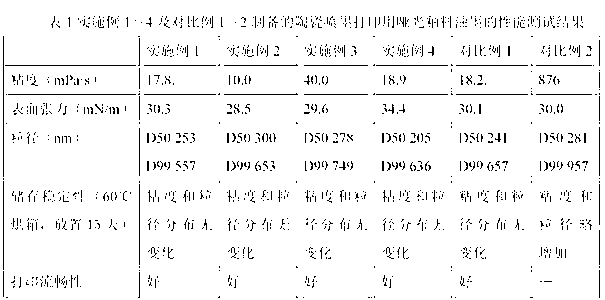

Examples

Embodiment 1

[0028] A matte glaze ink for ceramic inkjet printing, composed of the following components by mass percentage: 30% matte glaze, 8% polyurethane dispersant (BYK163), 5% alkyd resin (Novalkyd 2550X70C) , leveling agent (BYK306) 0.1%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK051) 0.3%, ethylene glycol butyl ether 18.5%, diethylene glycol methyl ether 28%.

[0029] Among them, the matte glaze, its raw material is composed of the following components by mass: SiO 2 50 parts, Al 2 o 3 25 copies, K 2 2 parts of O, Na 2 2 parts of O, 10 parts of CaO, 1 part of MgO, 5 parts of ZnO, and 10 parts of BaO; the preparation method thereof comprises the following steps: weighing each raw material component according to the proportion, mixing it and burning it into a frit at 1500°C, Then pulverize and pass through a 325-mesh sieve to obtain a matte glaze.

Embodiment 2

[0031] A matte glaze ink for inkjet printing of ceramics, composed of the following components by mass percentage: 35% matte glaze, 2% polyacrylate dispersant (EFKA4401), acrylic resin (W'CrylA 1218 ) 3%, leveling agent (BYK333) 0.2%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK051) 0.5%, ethylene glycol butyl ether 24%, diethylene glycol butyl ether 50% .

[0032] Among them, the matte glaze, its raw material is composed of the following components by mass: SiO 2 40 parts, Al 2 o 3 30 copies, K 2 O 4 parts, Na 2 2 parts of O, 1 part of CaO, 8 parts of MgO, and 5 parts of BaO; the preparation method thereof comprises the following steps: weighing each raw material component according to the proportion, mixing it, burning it into a frit at 1550° C., crushing it, and Pass through a 325-mesh sieve to obtain a matte glaze.

Embodiment 3

[0034]A matte glaze ink for inkjet printing of ceramics, composed of the following components in terms of mass percentage: 40% matte glaze, 10% polyacrylate dispersant (EFKA4400), acrylic resin (W'CrylA 2218 ) 5%, leveling agent (BYK333) 0.2%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK052) 0.4%, ethylene glycol butyl ether 14%, ethylene glycol ether acetate 20.3% .

[0035] Among them, the matte glaze, its raw material is composed of the following components by mass: SiO 2 70 parts, Al 2 o 3 20 copies, K 2 O 0.5 parts, Na 2 0.5 parts of O, 5 parts of CaO, 10 parts of MgO, and 10 parts of ZnO; the preparation method includes the following steps: weighing each raw material component according to the proportion, mixing it, burning it into a frit at 1530°C, and passing it through 325 mesh sieve, to get a matte glaze. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com