Photochromic ceramic ink capable of being sunken and used for ceramic ink jet and preparing method thereof

A photochromic, ceramic inkjet technology, applied in the field of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

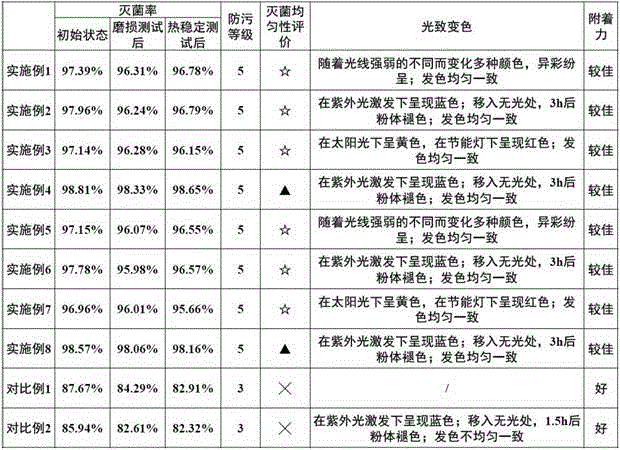

Examples

Embodiment 1

[0037] A sinkable photochromic ceramic ink for ceramic inkjet and a preparation method thereof, the preparation method comprising the following steps:

[0038] Step A. Preparation of sinking glaze: Mix 40% V2O5, 35% Bi2O3, 5% Ba2CO3, 5% ZnO, 2% SiO2, 2% Al2O3, 3% (K2O+Na2O) and sand them evenly; add 5% antibacterial compound and sanding evenly; then add 3% photochromic compound, sanding evenly to obtain a mixture; spread the mixture into a refractory sagger, and melt at a high temperature of 1000°C to obtain a molten slurry; The slurry is cooled by water quenching and broken into granules to obtain sunken glaze;

[0039] Step B. Weigh 20% sinking glaze, 8% Solsperse 24000, 5% Span-80, 0.3% BYK052, 3% polystyrene resin, 2% photochromic compound and 61.7% environmentally friendly hydrocarbon solvent, and add it to a high-speed mixer Disperse within 60 minutes; put the dispersed mixed solution into a sand mill, and sand mill for 10 hours to obtain a semi-finished ink with a part...

Embodiment 2

[0051] A sinkable photochromic ceramic ink for ceramic inkjet and a preparation method thereof, the preparation method comprising the following steps:

[0052] Step A. Preparation of sunken glaze: Mix and sand 33% V2O5, 40% Bi2O3, 7% Ba2CO3, 4% ZnO, 6% SiO2, 3% Al2O3, 2% (K2O+Na2O) evenly; add 3% antibacterial compound and sanding evenly; then add 2% photochromic compound, sanding evenly to obtain a mixture; spread the mixture into a refractory sagger, and carry out high-temperature melting at 1000°C to obtain a molten slurry; The slurry is cooled by water quenching and broken into granules to obtain sunken glaze;

[0053] Step B. Weigh 30% sinking glaze, 5% Solsperse 24000, 3% Span-80, 0.5% BYK052, 2% polystyrene resin, 3% photochromic compound and 56.5% environmentally friendly hydrocarbon solvent, add to high-speed mixer Disperse within 60 minutes; put the dispersed mixed solution into a sand mill, and sand mill for 10 hours to obtain a semi-finished ink with a particle si...

Embodiment 3

[0065] A sinkable photochromic ceramic ink for ceramic inkjet and a preparation method thereof, the preparation method comprising the following steps:

[0066] Step A. Preparation of sinking glaze: Mix and sand 30% V2O5, 43% Bi2O3, 11.5% Ba2CO3, 8% ZnO, 4% SiO2, 1%Al2O3, 1% (K2O+Na2O) evenly; add 0.5% antibacterial compound and sanding evenly; then add 1% photochromic compound, sanding evenly to obtain a mixture; spread the mixture into a refractory sagger, and melt at a high temperature of 1000°C to obtain a molten slurry; The slurry is cooled by water quenching and broken into granules to obtain sunken glaze;

[0067] Step B. Weigh 35% sinking glaze, 3% Solsperse 24000, 2% Span-80, 0.8% BYK052, 1% polystyrene resin, 1% photochromic compound and 57.2% environmentally friendly hydrocarbon solvent, add to high-speed mixer Disperse within 60 minutes; put the dispersed mixed solution into a sand mill, and sand mill for 10 hours to obtain a semi-finished ink with a particle size ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com