Ink for ceramic ink-jet printing and method for preparing same

A ceramic inkjet and ink technology, applied in inks, applications, household appliances, etc., can solve the problems of insufficient ink stability, non-spreading, light color, etc., achieve good inkjet printing performance, save production costs, particle size Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

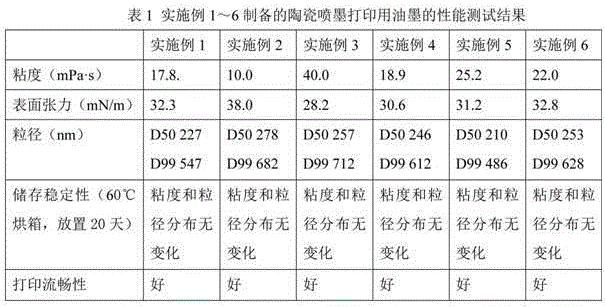

Examples

Embodiment 1

[0030] An ink for ceramic inkjet printing, composed of the following components by mass percentage: 40% black ceramic colorant, 8% polyurethane dispersant (BYK163), 5% alkyd resin (Novalkyd 2550X70C), leveling agent (BYK306) 0.1%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK051) 0.3%, ethylene glycol butyl ether 8.5%, diethylene glycol methyl ether 38%.

Embodiment 2

[0032] An ink for ceramic inkjet printing, composed of the following components by mass percentage: blue ceramic colorant 20%, polyacrylate dispersant (EFKA4400) 2%, acrylic resin (NeoCryl B-725) 3% , leveling agent (BYK333) 0.2%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK052) 0.7%, ethylene glycol butyl ether 18.5%, diethylene glycol butyl ether 55.5%.

Embodiment 3

[0034] An ink for ceramic inkjet printing, composed of the following components by mass percentage: 50% yellow ceramic pigment, 10% polyacrylate dispersant (EFKA4401), 5% acrylic resin (NeoCryl B-725), Leveling agent (BYK333) 0.2%, anti-settling agent (Disparlon NS-5501) 0.1%, defoamer (BYK052) 0.4%, butyl glycol ether 9.3%, diethylene glycol methyl ether 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com