Anti-static ceramic jet ink with marble crack effects and preparation method thereof

A ceramic inkjet and antistatic technology, applied in the field of ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

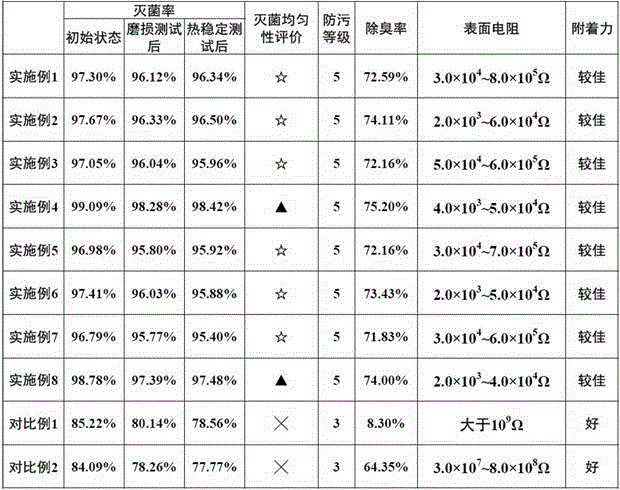

Examples

Embodiment 1

[0038] An antistatic ceramic ink-jet ink with a marble crack effect and a preparation method thereof, the preparation method comprising the following steps:

[0039] Step A. Mix and stir 18% abietyl alcohol, 5% Solsperse54000, 3% lauryl alcohol, 0.2% BYK-088 and 1.7% isomeric decanol polyoxyethylene ether E-05 to form a mixed solution, and then add 0.1% antibacterial compound Stir the material evenly, move it to a horizontal sand mill and continue stirring at 3500 rpm;

[0040] Step B. Slowly add 45% infiltration powder (V2O5, BiVO4, WO3, Bi2W3O12 mixed in a weight ratio of 2:1:3:1) and 8% conductive filler to the horizontal sand mill, and after adding Continue grinding until the average particle size of the ink is lower than 600nm, then add 18% undecanol and 1% deodorant, and continue grinding until the average particle size of the ink is controlled at 200-400nm to obtain a semi-finished ink;

[0041] Step C, put the ink semi-finished product obtained in step B in a constant...

Embodiment 2

[0053] An antistatic ceramic ink-jet ink with a marble crack effect and a preparation method thereof, the preparation method comprising the following steps:

[0054] Step A. Mix and stir 18% abietyl alcohol, 5% Solsperse54000, 3% lauryl alcohol, 0.2% BYK-088 and 1.3% isomeric decanol polyoxyethylene ether E-05 to form a mixed solution, and then add 2.5% antibacterial compound Stir the material evenly, move it to a horizontal sand mill and continue stirring at 3500 rpm;

[0055] Step B. Slowly add 44% infiltration powder (V2O5, BiVO4, WO3, Bi2W3O12 mixed in a weight ratio of 2:1:3:1) and 5% conductive filler to the horizontal sand mill, and after adding Continue to grind until the average particle size of the ink is below 600nm, then add 18% undecanol and 3% deodorant, and continue to grind until the average particle size of the ink is controlled at 200-400nm to obtain a semi-finished ink;

[0056] Step C, put the ink semi-finished product obtained in step B in a constant temp...

Embodiment 3

[0068] An antistatic ceramic ink-jet ink with a marble crack effect and a preparation method thereof, the preparation method comprising the following steps:

[0069] Step A. Mix and stir 16% abietyl alcohol, 5% Solsperse54000, 3% lauryl alcohol, 0.2% BYK-088 and 1.8% isomeric decanol polyoxyethylene ether E-05 to form a mixed solution, and then add 5% antibacterial compound Stir the material evenly, move it to a horizontal sand mill and continue stirring at 3500 rpm;

[0070] Step B. Slowly add 45% infiltration powder (V2O5, BiVO4, WO3, Bi2W3O12 mixed in a weight ratio of 2:1:3:1) and 3% conductive filler to the horizontal sand mill, and after adding Continue grinding until the average particle size of the ink is lower than 600nm, then add 16% undecanol and 5% deodorant, and continue grinding until the average particle size of the ink is controlled at 200-400nm to obtain a semi-finished ink;

[0071] Step C, put the ink semi-finished product obtained in step B in a constant t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com