Peel glaze ink for ceramic ink-jet printing

A ceramic inkjet and glaze removal technology, applied in inks, applications, household appliances, etc., can solve the problems of unsatisfactory stability and printing performance, complicated preparation process, etc., and achieve good inkjet printing performance and stability. Good, the effect of reducing material waste and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

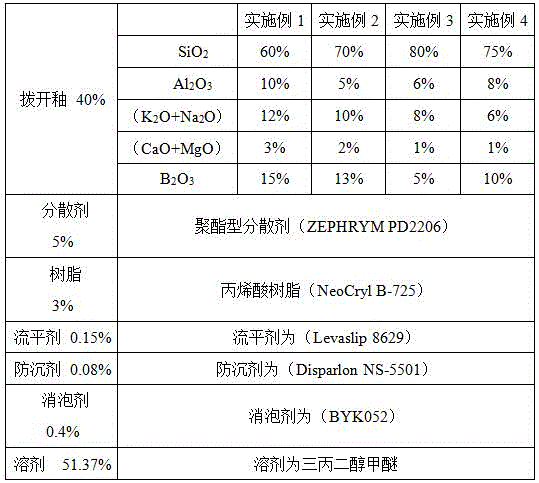

[0022] The present invention will be further described below in conjunction with specific embodiments, but it is not limited to this. A kind of glaze ink for ceramic inkjet printing, calculated by mass percentage, as shown in the following table:

[0023] Table 1. Composition of different embodiments

[0024]

[0025] Table 1 lists the formula composition of the peeling glaze ink for ceramic inkjet printing in Examples 1 to 4. The preparation method includes the following steps: (1) Pre-dispersing the solvent, resin, dispersant, and peeling glaze through a high-speed disperser , So that the glaze is fully wetted; (2) Grind the pre-dispersed material with a grinder for 2 to 4 hours, so that the average diameter of the glaze is 300-500 nm and the maximum particle size is less than 1 μm, to obtain a glaze slurry; (3) Add a leveling agent, a defoamer, and an anti-settling agent to the glaze slurry, disperse it evenly, and filter it with a 1 micron filter element to obtain a glaze ink ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com