UV nano red paste and preparation method thereof and UV ink

A nano-ink technology, applied in inks, pigment pastes, household utensils, etc., can solve problems such as the difficulty in balancing ink wet fastness and fluency, and achieve good inkjet printing performance, small particle size, and good toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The second aspect of the embodiment of the present application provides a method for preparing UV nano-red pulp, comprising steps:

[0037] S10. After the acrylate monomer, the dispersant, the red pigment and the auxiliary agent are mixed, the grinding treatment is carried out to obtain the first mixed slurry;

[0038] S20. Carrying out sequential centrifugation and filtration on the first mixed slurry to obtain UV nano-red slurry.

[0039] The preparation method of UV nano red paste provided by the second aspect of the application, after mixing the acrylate monomer, dispersant, red pigment and auxiliary agent, and then performing grinding treatment, centrifugation treatment and filtration treatment in turn, can obtain UV nano red pulp. The preparation process is simple, the operation is convenient, it is suitable for large-scale industrial production and application, and the particle size of the prepared UV nano red pulp is small and uniform, no aggregation and sedime...

Embodiment 1~3

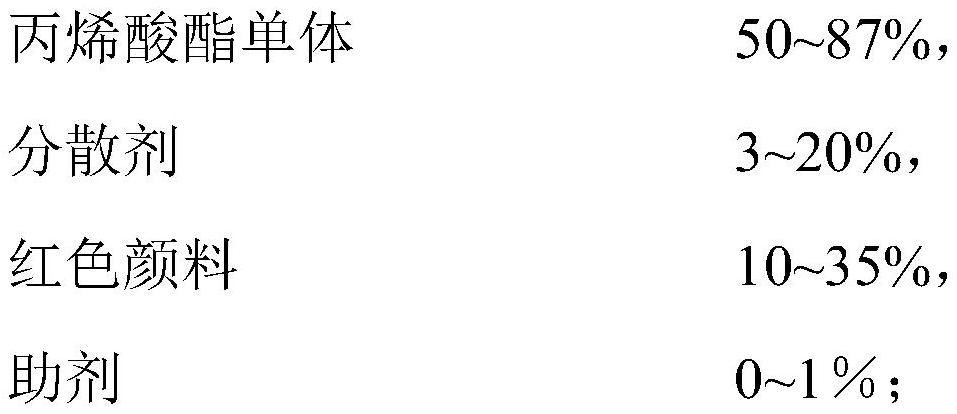

[0056] Embodiments 1 to 3 respectively provide a UV nano-red paste, the raw material formula of which is shown in Table 1 below, and the preparation steps include: after mixing the acrylate monomer, dispersant, red pigment and auxiliary agent, followed by Grinding treatment, centrifugation treatment and filtration treatment to obtain UV nanometer red pulp.

Embodiment 4~9

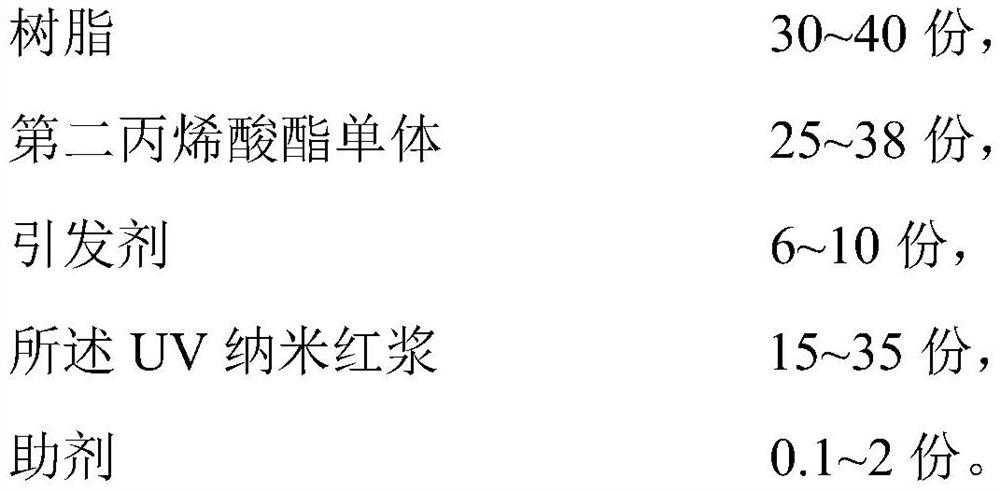

[0064] Embodiments 4-9 respectively provide a kind of UV ink, and its raw material formula is as shown in Table 2 below:

[0065] Table 2

[0066]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com