High-temperature sintering heating conductive ink and preparation method of high-temperature sintering heating conductive ink

A conductive ink, high-temperature sintering technology, applied in the direction of ink, heating element materials, sustainable manufacturing/processing, etc., can solve the problems of low working temperature of electric energy conversion heat energy, lack of far-infrared function, and inability to be used as high resistance to achieve heat generation Fast speed, wide application range, and wide controllable heating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

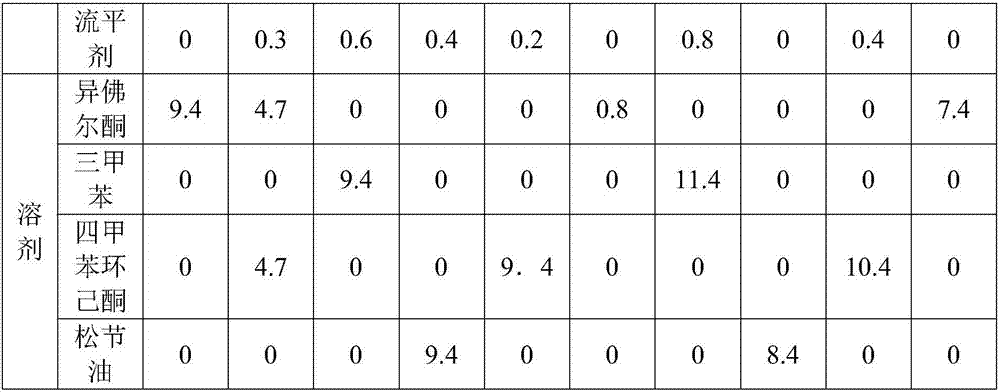

[0037] In order to simplify the description, the components and ratios of the high-temperature sintering heat-generating conductive inks in Example 1 to Example 5 are listed in Table 1.

[0038] Table 1. Component composition and mass ratio of high-temperature sintering heat-generating conductive ink in Example 1 to Example 5

[0039]

[0040]

[0041] The preparation method of the high-temperature sintering heat-generating conductive ink in the corresponding embodiment is as follows:

Embodiment 1

[0043] Weigh each component according to the composition and mass ratio of the high-temperature sintering heat-generating conductive ink in Table 1;

[0044] Add graphene, copper chrome black, tourmaline powder, glass powder, corresponding resin and corresponding additives to the corresponding solvent, fully stir, and ultrasonically disperse. Specifically, the ultrasonic dispersion operation conditions are: frequency is 30k, power is 600w, The dispersion time is 12 hours; then a ball mill is used for ball milling, the operating condition is that the speed of the ball mill is 2000 rpm, and the ball milling time is 12 hours; then it is ground with a three-roller machine until the fineness of the ink slurry is below 15 μm, and then filtered to obtain High temperature sintering heating conductive ink.

Embodiment 2

[0046] Weigh each component according to the composition and mass ratio of the high-temperature sintering heat-generating conductive ink in Table 1;

[0047] Add graphene, copper chrome black, tourmaline powder, glass powder, corresponding resins and corresponding additives to the corresponding solvent, fully stir, and ultrasonically disperse. Specifically, the ultrasonic dispersion operation conditions are: frequency of 20k, power of 200w, The dispersion time is 24 hours; then the ball mill is used for ball milling, the operating condition is that the speed of the ball mill is 2000 rpm, and the ball milling time is 48 hours; then the three-roll machine is used to grind the ink slurry until the fineness of the ink slurry reaches 15 μm or less, and then filter to obtain the corresponding High temperature sintering heating conductive ink.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com