Copper-chrome black pigment and preparation method thereof

A technology for copper chrome black and pigments, which is applied in the directions of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of high production cost and complicated production process of copper chrome black, and achieves low product cost, chromous acid The effect of complete copper crystal and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A kind of copper chrome black pigment that the present invention proposes can be formulated by the raw material of following weight percentage content:

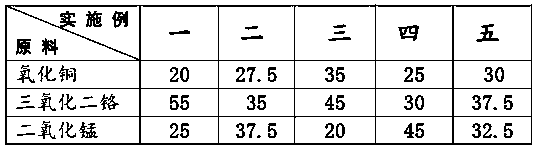

[0023] Copper oxide 20-35%, chromium trioxide 35-55%, manganese dioxide 20-45%. Among them, the particle size of copper oxide, chromium oxide and manganese dioxide raw materials is D 50 ≤2μm. According to needs, different raw material ratios can be selected to prepare copper chrome black pigments. Such as the raw material proportioning of different embodiments shown in the following table 1:

[0024]

[0025] Begin to prepare copper chrome black pigment according to above-mentioned raw material proportioning, preparation method step is as follows:

[0026] Step 1: Check whether the particle size of the raw materials copper oxide, chromium oxide and manganese dioxide meets D 50 ≤2μm, if it does not meet this requirement, it needs to be sanded first until the particle size requirement is reached, then weigh each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com