Catalyst for preparing 1, 6-hexanediol by hydrogenating dimethyl adipate, and preparation method and application thereof

The technology of dimethyl adipate and catalyst is applied in the field of catalyst for preparing 1,6-hexanediol by hydrogenation of dimethyl adipate and the field of preparation thereof, and can solve the problem of low processing capacity of dimethyl adipate, low processing capacity of dimethyl adipate, low processing capacity of dimethyl adipate. Reduce production and operating costs, short service life and other issues, to achieve the effect of improving unit processing capacity, prolonging residence time, and reducing ventilation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

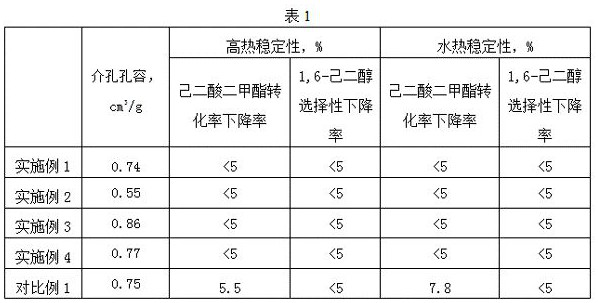

Examples

Embodiment 1

[0029] The catalyst for preparing 1,6-hexanediol by hydrogenation of dimethyl adipate in this example is composed of a carrier and an active component dispersed and supported on the carrier; the active component is composed of the first active component and the second active component, the first active component is ruthenium, the second active component is copper chromite; the carrier is lanthanum-doped SiO 2 / ZrO 2 Carrier; the carrier is a mesoporous structure with a pore size of 10-50 nm.

[0030] The content of the active component is 29wt%, and the content of the carrier is 71wt%.

[0031] The mass ratio of the first active component to the second active component is 1:16.

[0032] The preparation method of present embodiment catalyst, it comprises the following steps:

[0033] S1 Carrier Preparation: Dissolve lanthanum nitrate, sodium silicate and zirconium nitrate in deionized water to prepare a mixed solution A; in an ice-water bath, slowly add the mixed solution A ...

Embodiment 2

[0039] The catalyst for preparing 1,6-hexanediol by hydrogenation of dimethyl adipate in this example is composed of a carrier and an active component dispersed and supported on the carrier; the active component is composed of the first active component and the second active component, the first active component is iridium, the second active component is copper chromite; the carrier is lanthanum-doped SiO 2 / ZrO 2 Carrier; the carrier is a mesoporous structure with a pore size of 10-50 nm.

[0040] The content of the active component is 35wt%, and the content of the carrier is 65wt%.

[0041] The mass ratio of the first active component to the second active component is 1:10.

[0042] The preparation method of present embodiment catalyst, it comprises the following steps:

[0043] S1 Carrier Preparation: Dissolve lanthanum nitrate, sodium silicate and zirconium nitrate in deionized water to prepare a mixed solution A; in an ice-water bath, slowly add the mixed solution A to...

Embodiment 3

[0049] The catalyst for preparing 1,6-hexanediol by hydrogenation of dimethyl adipate in this example is composed of a carrier and an active component dispersed and supported on the carrier; the active component is composed of the first active component and the second active component, the first active component is ruthenium, the second active component is copper chromite; the carrier is lanthanum-doped SiO 2 / ZrO 2 Carrier; the carrier is a mesoporous structure with a pore size of 10-50 nm.

[0050] The content of the active component is 20wt%, and the content of the carrier is 80wt%.

[0051] The mass ratio of the first active component to the second active component is 1:25.

[0052] The preparation method of present embodiment catalyst, it comprises the following steps:

[0053] S1 Carrier Preparation: Dissolve lanthanum nitrate, sodium silicate and zirconium nitrate in deionized water to prepare a mixed solution A; in an ice-water bath, slowly add the mixed solution A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com