Geopolymer coating and preparation method and application thereof

A technology of geopolymer and polymer, which is applied in the field of geopolymer coating and its preparation, can solve the problems of poor surface adhesion of metal materials, large metal expansion coefficient, and affecting the thermal efficiency of kilns, so as to contribute to thermal efficiency, attachment The effect of strong force and good heat radiation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

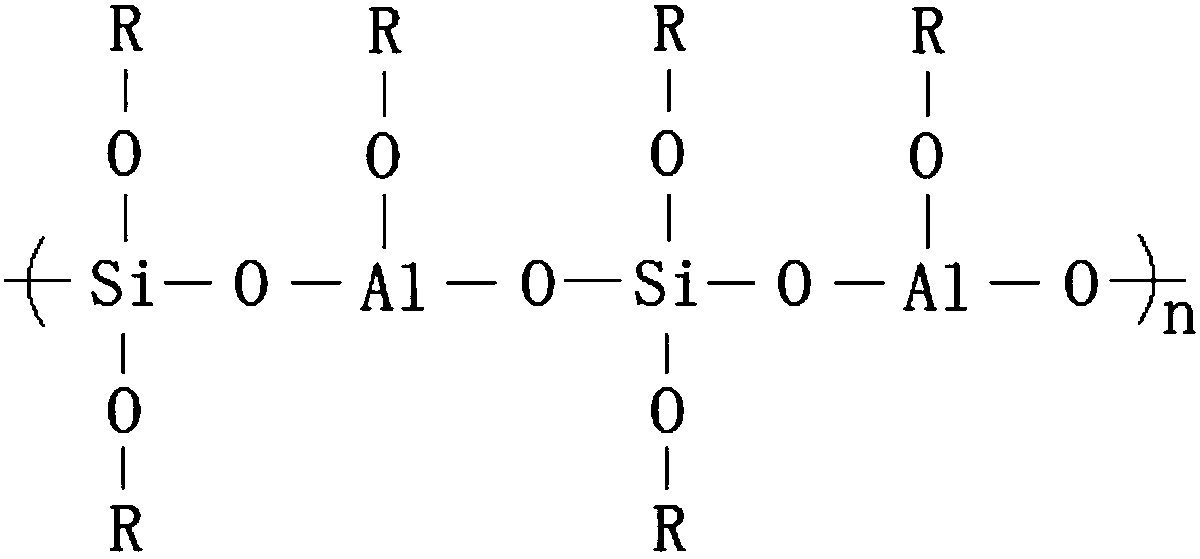

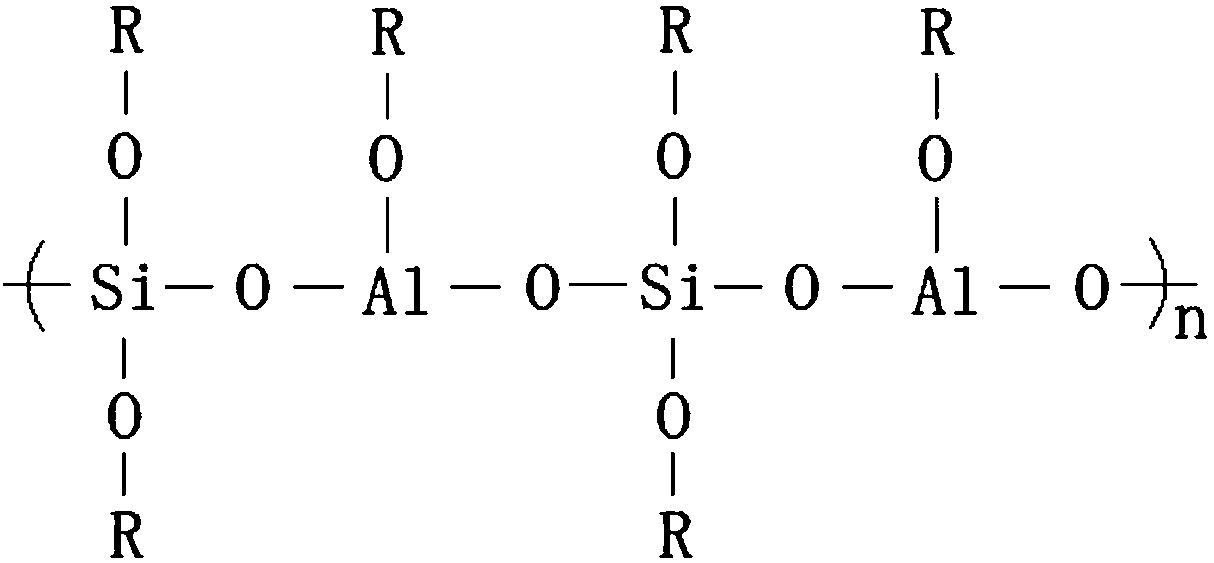

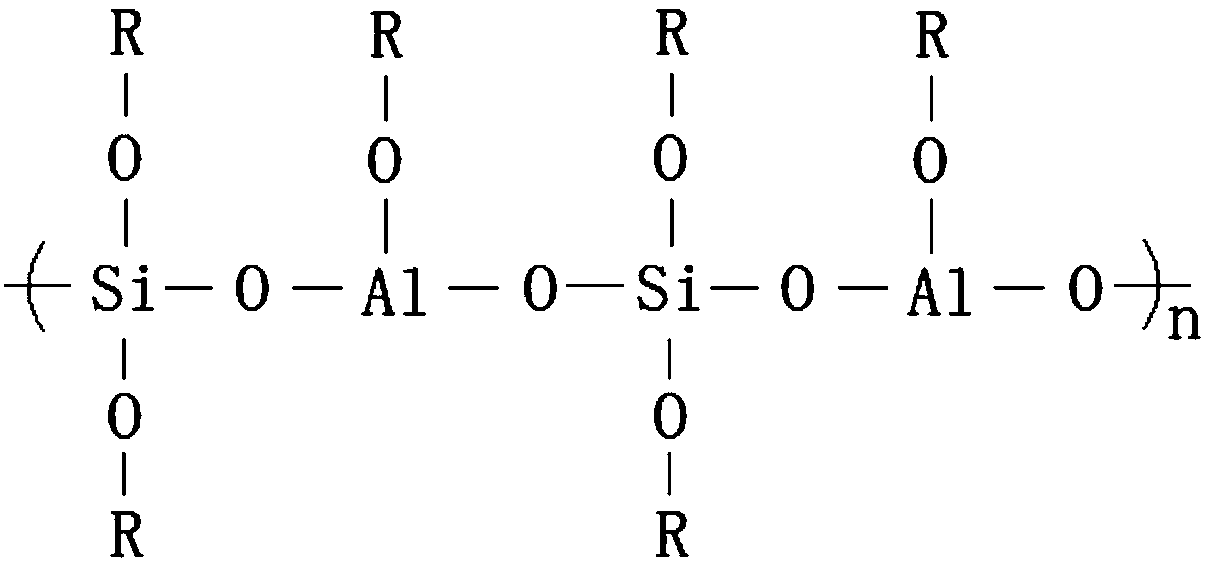

Method used

Image

Examples

preparation example Construction

[0032] In the second aspect, the embodiment of the present invention provides a method for preparing the above-mentioned geopolymer coating, the method comprising: mixing copper chrome black, thermally conductive fillers, and metakaolin, and grinding for 1-3 hours to obtain component A; Mix the salt binder with water to form a binder solution to obtain component B; mix component A and component B evenly to obtain a coating.

[0033] In order to prolong the storage time of geopolymer coatings, operators usually add thickeners, dispersants, etc. to the high-temperature radiation-resistant coatings to avoid the settlement problem caused by long-term storage of the coatings. However, in the geopolymer coating provided by the embodiment of the present invention, the substances in the components are made into component A and component B respectively, and placed separately. When in use, mix component A and component B, and after stirring evenly, the paint can be applied without addin...

Embodiment 1

[0048] This embodiment provides a geopolymer coating, which is prepared using the following components in parts by weight:

[0049] 100 parts of copper chrome black, 200 parts of graphite powder, 100 parts of potassium silicate, 50 parts of metakaolin, and 500 parts of water.

[0050] Among them, the particle size of copper chromium black is 10,000 mesh, the particle size of graphite powder is 2,000 mesh, the modulus of potassium silicate is 3.0, and metakaolin is prepared by calcining ultrafine kaolin at 600°C for 3 hours and grinding to 4,000 mesh.

[0051] The geopolymer coating is prepared by the following method:

[0052] Mix copper chromium black, graphite powder, and metakaolin, and grind for 1 hour to obtain component A in powder form with a particle size of 2000 mesh.

[0053] Potassium silicate is mixed with water to form a binder solution to obtain the B component.

[0054] Mix components A and B evenly to obtain a geopolymer coating.

Embodiment 2

[0056] This embodiment provides a geopolymer coating, which is prepared using the following components in parts by weight:

[0057] 100 parts of copper chrome black, 100 parts of graphene powder, 100 parts of aluminum silicate, 200 parts of sodium silicate, 150 parts of metakaolin, and 1000 parts of water.

[0058] Among them, the particle size of copper chromium black is 5000 mesh, the particle size of graphene powder is 10000 mesh, the modulus of aluminum silicate and sodium silicate is 3.5, and the metakaolin is calcined at 1500 ℃ for 1 hour by ultrafine kaolin, and ground to 1500 Prepared.

[0059] The geopolymer coating is prepared by the following method:

[0060] Mix copper chrome black, graphene powder, and metakaolin, and grind for 2 hours to obtain component A in powder form with a particle size of 10,000 mesh.

[0061] Mix aluminum silicate, sodium silicate and water to form a binder solution to obtain component B.

[0062] Mix components A and B evenly to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com