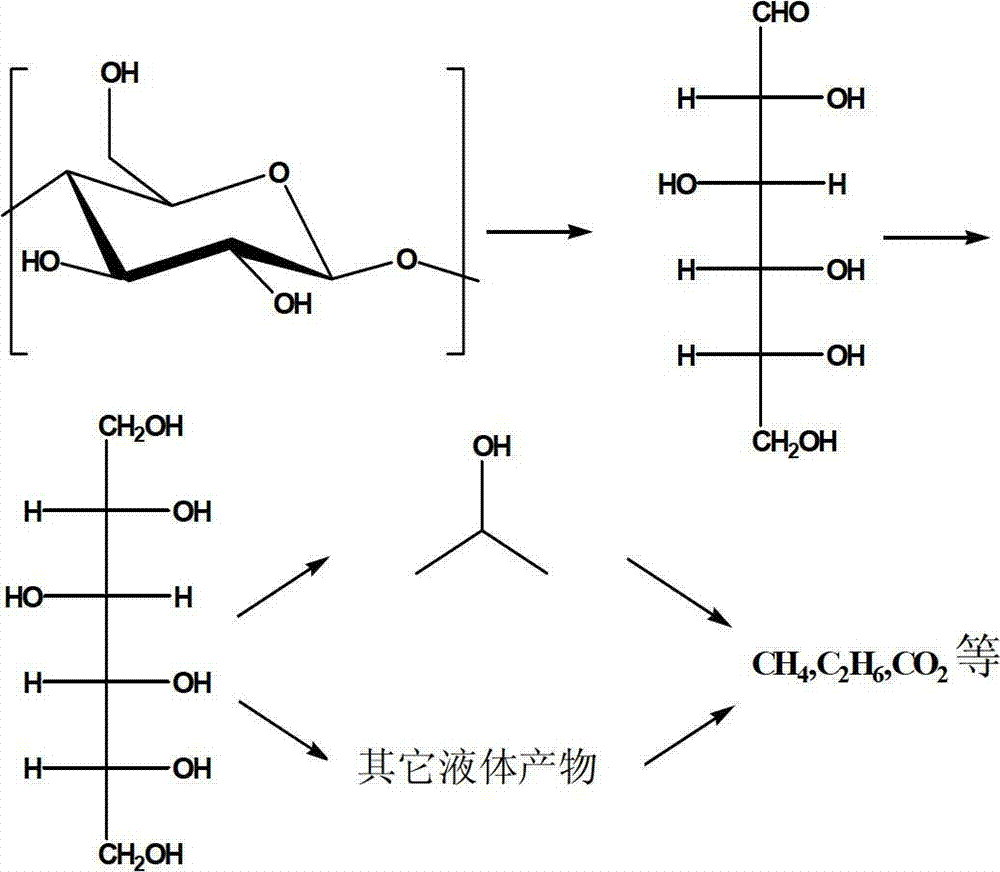

Method of preparing isopropanol by catalytic conversion of cellulose

A technology for cellulose and isopropanol, applied in the field of isopropanol production, can solve the problems of pre-treatment increasing manufacturing cost, affecting catalytic conversion, low reaction concentration, etc., and achieving excellent isopropanol selectivity, good activity and selectivity , the effect of high isopropanol yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

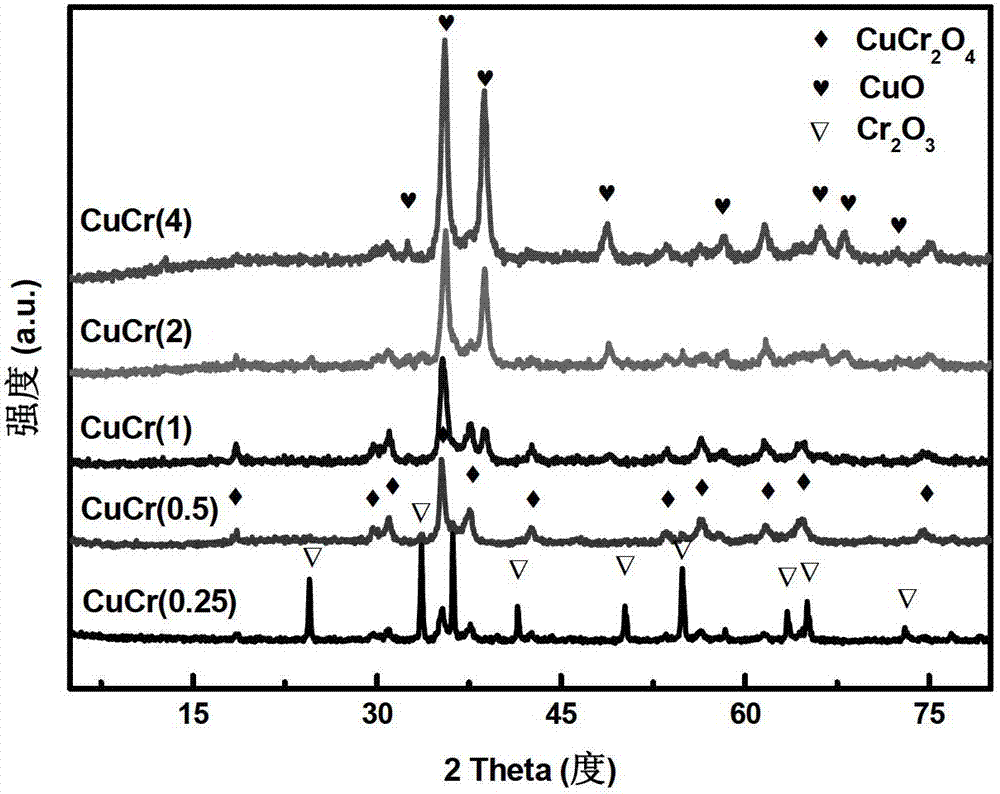

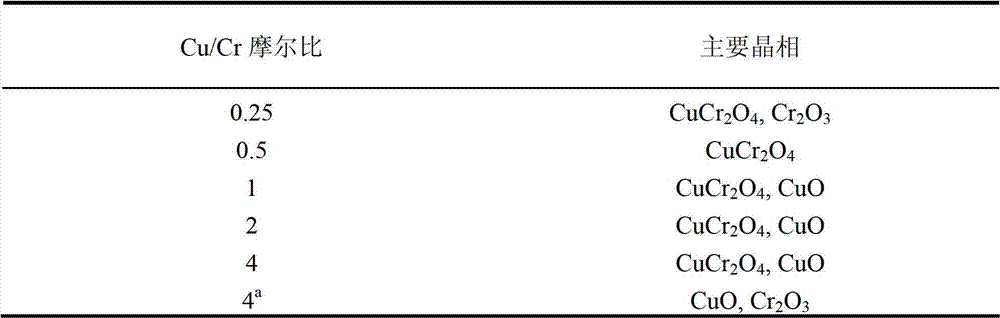

[0020] 1. Preparation of copper chromium catalyst

[0021] The preparation of the catalyst in this example can refer to C.Liang, Z.et al., Catal.Lett. (2009), 130, 169-176; Z.Ma et al., J.Mater.Chem. (2010), 20,755 -760; and Z. Xiao et al., Ind. Eng. Chem. Res. (2011), 50, 2031-2039, which are hereby incorporated by reference in their entirety. Specifically, the following methods can be used:

[0022] (1) Sol-gel method

[0023] Preparation of Cr (NO 3 ) 3 9H 2 O and Cu (NO 3 ) 2 ·3H 2 O in ethanol solution (the metal mass concentration is 0.3 grams per milliliter (g / mL)), and the molar ratios of metal Cu / Cr are controlled to be 0.25, 0.5, 1, 2 and 4, respectively. At 60°C, 18 mL of propylene oxide was added with stirring to obtain a gel. After being dried overnight at 85°C, it was calcined at 500°C in an air atmosphere for 2 hours (h) to obtain a copper-chromium catalyst.

[0024] (2) Carbon template method

[0025] Preparation of Cr (NO 3 ) 3 9H 2 O and Cu (NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com