Preparation of nano copper chromite using microemulsion method

A copper chromite, nano technology, applied in the field of nano materials, can solve the problems of uneven mixing of ultra-fine copper chromite and ultra-fine ammonium perchlorate, affecting the catalytic effect, and insufficient contact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

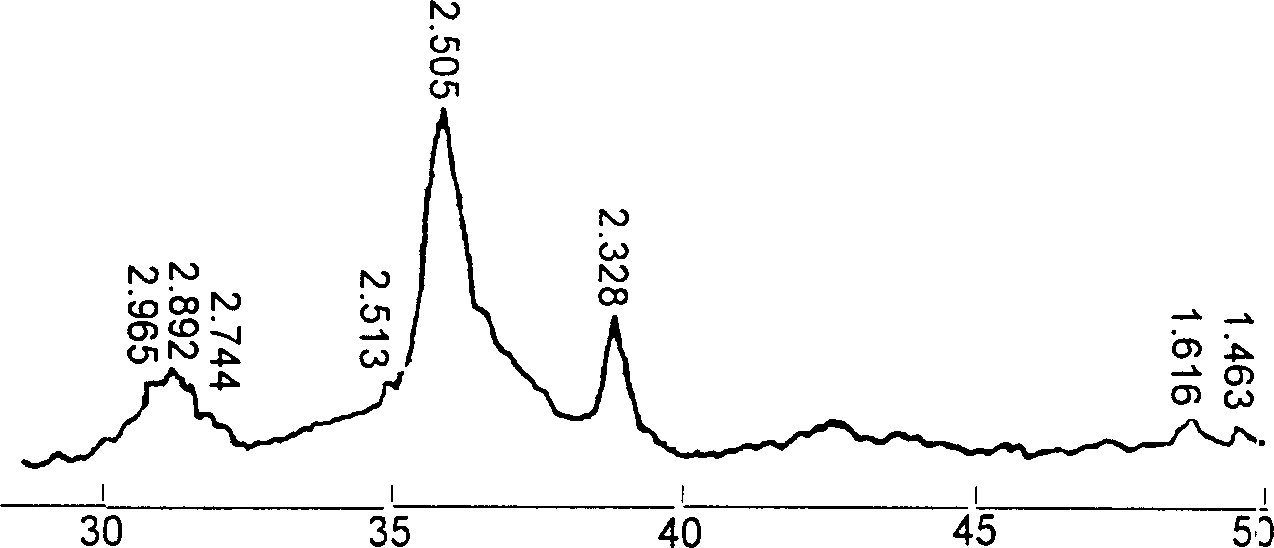

[0044] X-ray Diffraction Analysis of Nanoscale Copper Chromite

[0045] Prepare nanoscale copper chromite with the following procedure:

[0046] Toluene is used as the oil phase of the microemulsion, the ammonia solution of copper sulfate solution and potassium dichromate is used as the water phase, and the emulsifier is a mixture of Span80 and Tween80 (1%-2% Span80 and 2%-3 %Tween80). Wherein, the ratio of each component of the mixed surfactant is adjusted to the optimum HLB value (˜6) of the water / toluene system through previous experiments. Mix toluene, water and emulsifier, ultrasonically emulsify in an ultrasonic cleaner at room temperature for 15 minutes, and the copper sulfate solution and the ammonia solution of potassium dichromate are mixed at a certain speed (10 ml / min, based on 500 ml of reaction system) ) was added dropwise into the microemulsion to form a colloidal precipitate, and the emulsion remained non-layered at the reaction temperature (40°C). After the ...

Embodiment 2

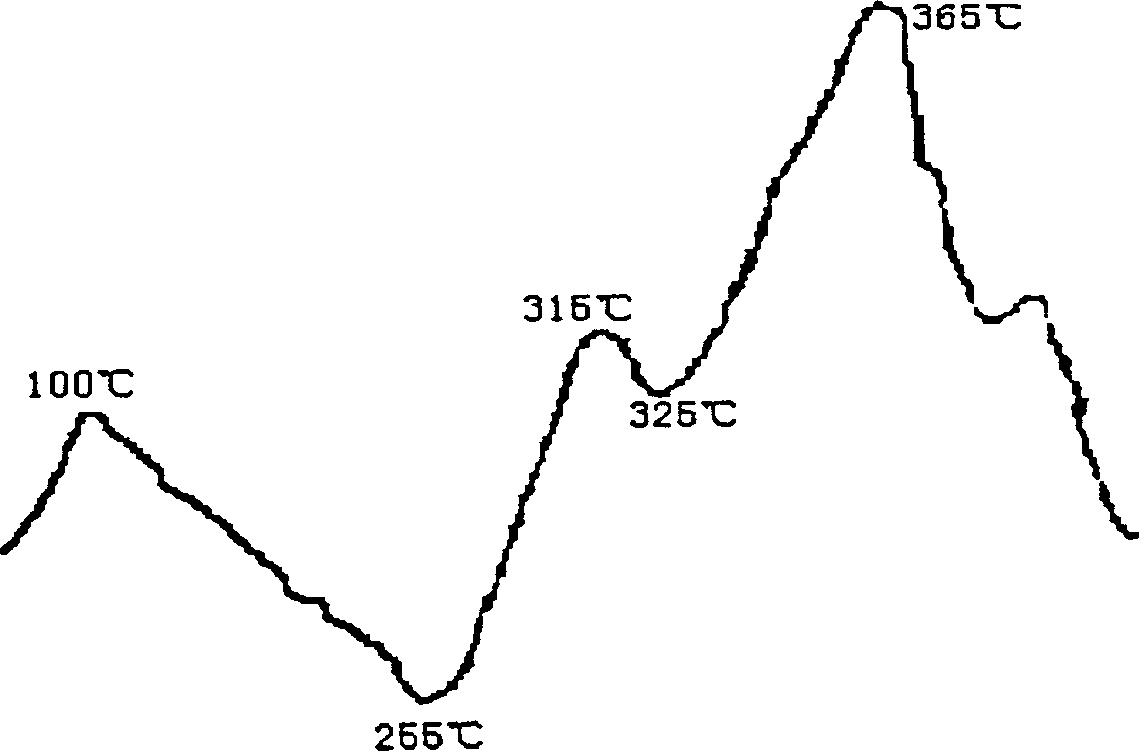

[0051] Differential thermal analysis of nanoscale copper chromite

[0052] Activation is an important step that affects the quality of the catalyst. In the activation process, dehydration is first: then Cu(OH)NH 4 CrO 4 Decomposes to form active copper chromite. Thermal analysis gave a good description of the catalyst activation process. figure 2 It is the differential thermal curve of nano-scale copper chromite prepared by the above-mentioned experimental method. It can be seen from the graph that both of them have endothermic peaks at 100°C and 365°C. Obviously, the low temperature position is equivalent to the dehydration zone, and the high temperature position is equivalent to Cu(OH)NH 4 CrO 4 Decomposition area. There is also an exothermic peak at 255 °C in the figure, which means that the active species is formed at this temperature. Tests have proved that the optimum temperature for catalyst activation is 250°C-260°C, so the activation temperature should be contr...

Embodiment 3

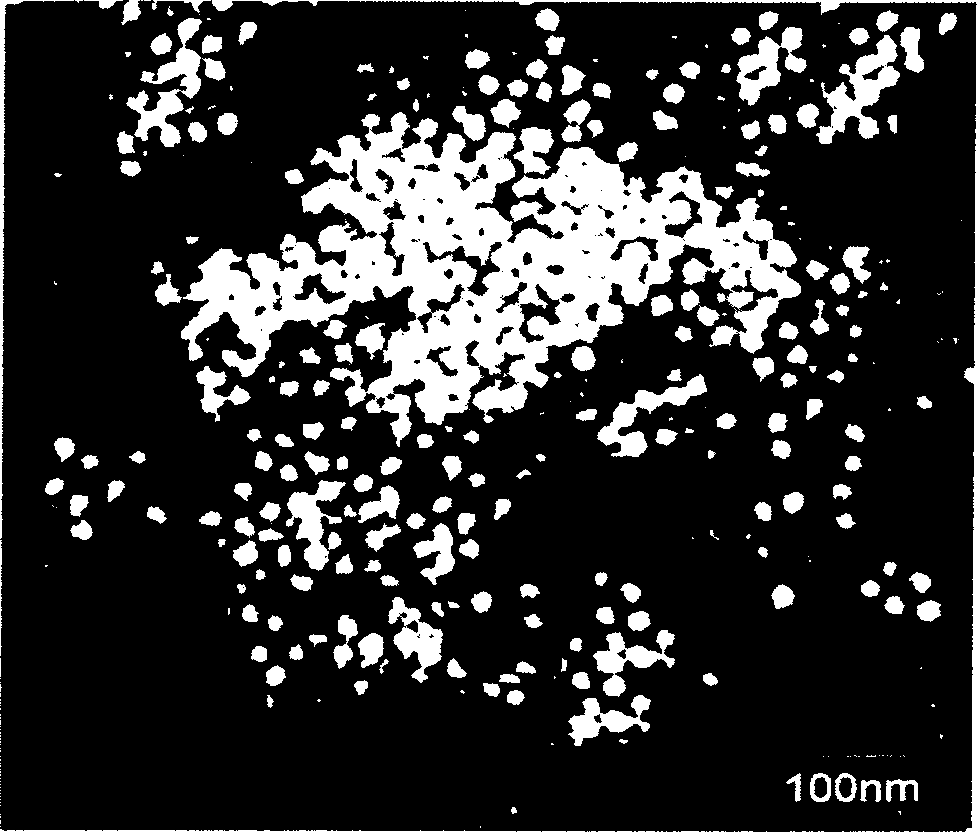

[0054] Preparation of composite particles

[0055] Grinding ammonium perchlorate with a high-energy ball mill to obtain superfine particles of ammonium perchlorate. Adjust the rotation speed and grind for an appropriate time so that the particle size of ammonium perchlorate is 0.5-0.2um. The reason why this particle size range is selected is that if the particle size is less than 0.2um, the size ratio to the copper chromite particle is too small. Compounding is not easy. After the ammonium perchlorate superfine particle is obtained, the stirring mill speed is turned down, and nano-scale copper chromite ( image 3 ), so that the two are mixed in the grinding chamber. After a certain period of time, stop the machine and obtain the ammonium perchlorate composite particles prepared by the high-energy ball milling method. From its electron micrograph ( Figure 4 ) It can be seen that the composite particles are copper chromite particles embedded and adhered to the surface of amm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com