Syndiotactic polystyrene flame-retardant composite material

A flame-retardant composite material and polystyrene technology, applied in the field of polymer materials, can solve the problems of low heat resistance and flame retardancy, limited application range, organic solvent pollution, etc., and achieve good durability and flexible processing methods , the effect of improving the impact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

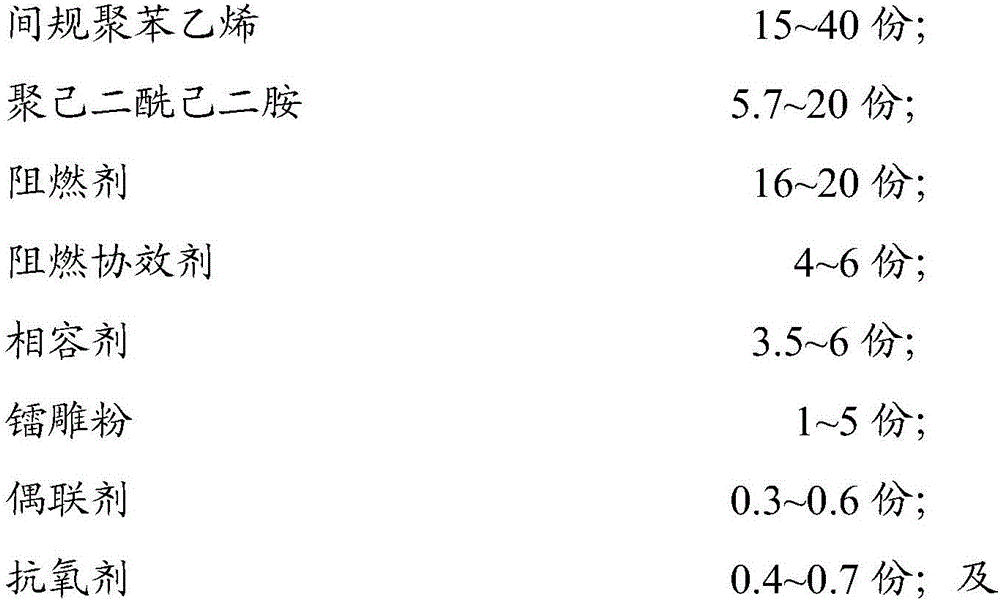

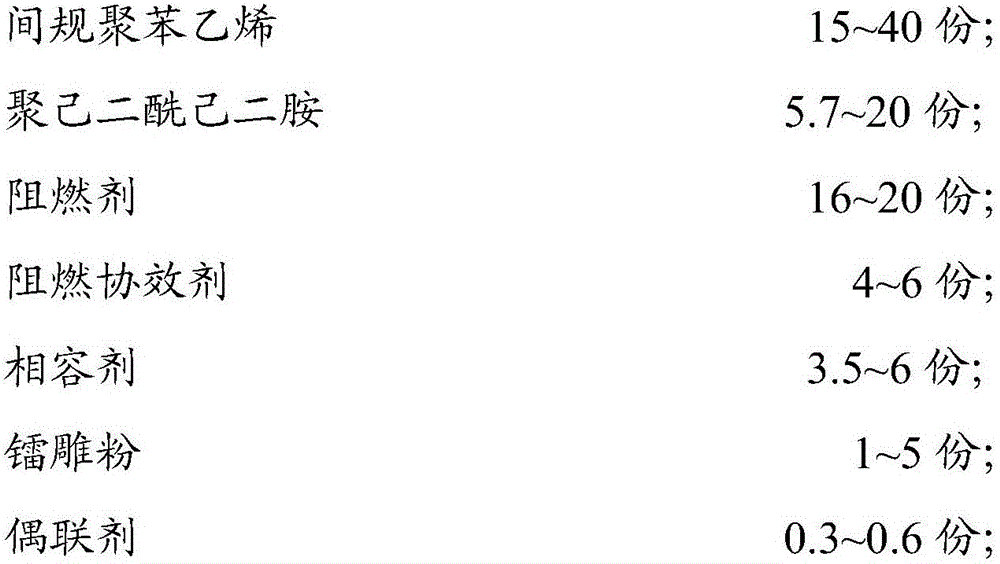

[0038] The preparation method of the above-mentioned syndiotactic polystyrene flame-retardant composite material comprises the following steps:

[0039] Step S110, drying the sPS and PA66.

[0040] In one embodiment, the sPS and PA66 are air-dried at 100° C. to 120° C. for 1 hour to 4 hours, respectively.

[0041] Of course, when the sPS and PA66 are relatively dry, no drying treatment is required, and step S110 can be omitted.

[0042] Step S120, after stirring and mixing the dried sPS and PA66 with a compatibilizer and a coupling agent evenly, adding laser engraving powder, antioxidant, nucleating agent and auxiliary agent in sequence and mixing evenly to obtain a premix.

[0043] In one of the embodiments, add the dried sPS and PA66, compatibilizer and coupling agent into the mixer, stir and mix at the speed of 200 rpm to 500 rpm for 1 minute to 3 minutes, and wait for the mixer to stop Finally, add flame retardant, flame retardant synergist, radium engraving powder, anti...

Embodiment 1

[0051] Select the sPS resin with a syndiotacticity of 97%, a weight-average molecular weight of 300,000, and a PA66 resin with an intrinsic viscosity of 3.0dl / g. After blast drying at 120°C for 3 hours, dry 40 parts of sPS, Add 20 parts of PA66, 4.2 parts of hydrogenated styrene-butadiene-styrene block copolymer grafted maleic anhydride, and 0.4 parts of KH550 (silane coupling agent) into the mixer in turn, and stir and mix at a speed of 200 rpm After stirring for 3 minutes, after the mixer stopped, 12.1 parts of decabromodiphenylethane, 6 parts of brominated polystyrene, 3 parts of antimony trioxide (average particle size of 0.9 microns), 2 parts of kaolin (average Particle size is 1.2 microns), 0.3 parts titanium dioxide (average particle size is 0.3 microns), 0.2 parts neodymium oxide (average particle size is 0.5 microns), 0.2 parts bismuth oxide (average particle size is 0.5 microns), 0.3 parts basic phosphoric acid Copper (average particle size is 1.3 micron), 0.2 part o...

Embodiment 2

[0055] Select the sPS resin with a syndiotacticity of 97.5%, a weight average molecular weight of 400,000, and a PA66 resin with an intrinsic viscosity of 2.7dl / g. After drying for 3 hours at 120°C, 35 parts of dried sPS, 11.5 parts of PA66, 5 parts of compatibilizer acrylate-glycidyl ester-ethylene copolymer, 0.3 parts of isopropyl tris(dioctyl pyrophosphate acyloxy) titanate coupling agent were added to the mixer in turn, and at 250 rpm After stirring and mixing at a speed of 1 / min for 2 minutes, after the mixer stopped, add 16 parts of decabromodiphenylethane, 3 parts of antimony trioxide (average particle diameter is 0.9 micron), 3 parts of montmorillonite ( The average particle size is 0.5 microns), 3 parts of barium sulfate (average particle size is 2.6 microns), 1 part of tin oxide (average particle size is 0.7 microns), 1 part of copper chromite (average particle size is 0.5 microns), 0.3 Part of antioxidant 1076, 0.4 part of antioxidant 168, 0.2 part of nucleating age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com