Environment-friendly copper ruby glass glaze, preparation method of environment-friendly copper ruby glass glaze and method for preparing copper ruby glass glaze surface from environment-friendly copper ruby glass glaze

A technology of glass glaze and copper red, applied in the direction of coating, etc., can solve the problems of affecting the decorative effect and uneven color of glass glaze, and achieve the effect of consistent expansion coefficient, uniform distribution of tin, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

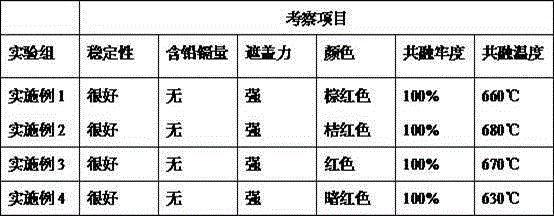

Examples

Embodiment 1

[0062] The glass glaze of this embodiment is made of basic glaze and coloring agent, and each component of basic glaze is calculated as follows by weight percentage: 45%SiO 2 ;25%ZnO;3%CaO+MgO;2%BaO;1%SrO;6%B 2 o 3 ;0.5%Al 2 o 3 ;2%TiO 2 ;4%ZrO 2 ;6%K2 O+Na 2 O; 3%Li 2 O; 2.5%CuO; The manufacturing process of glass colored glaze is as follows:

[0063] Put all the raw materials weighed into a ball mill and ball mill for 15 minutes at a speed of 80 rpm, and mix well;

[0064] Melt the obtained mixture at 1250°C to completely melt the mixture to obtain molten glass;

[0065] The molten glass liquid is water-quenched, and the glass frit after water-quenching is put into a ball mill for ball milling for 3 hours at a speed of 100 rpm to obtain glass powder;

[0066] The ball-milled glass powder is dried in a drying oven at 120°C, and the obtained powder is copper red glass glaze.

[0067] The prepared copper-red glass glaze is prepared into a glaze slurry with the blendin...

Embodiment 2

[0072] A glass colored glaze is mainly composed of a base glaze and a colorant, and the components of the base glaze are calculated by weight percentage as follows: 50% SiO 2 ;15%ZnO;5%CaO+MgO;2%BaO;1%SrO;10%B 2 o 3 ;1%Al 2 o 3 ;2%TiO 2 ;2%ZrO 2 ;8%K 2 O+Na 2 O; 3%Li 2 O; 1%CuCO 3 ; The manufacturing process of glass colored glaze is as follows:

[0073] Put all the raw materials weighed into a ball mill and ball mill for 15 minutes at a speed of 80 rpm, and mix well;

[0074] Melt the obtained mixture at 1300°C to completely melt the mixture to obtain molten glass;

[0075] The molten glass liquid is water-quenched, and the glass frit after water-quenching is put into a ball mill for ball milling for 3 hours at a speed of 100 rpm to obtain glass powder;

[0076] The ball-milled glass powder is dried in a drying oven at 120°C, and the obtained powder is copper red glass glaze.

[0077] The prepared copper-red glass glaze and the blending agent are prepared into gla...

Embodiment 3

[0082] A glass colored glaze is mainly composed of a base glaze and a colorant, and the components of the base glaze are calculated by weight percentage as follows: 55%SiO 2 ;15%ZnO;5%CaO+MgO;1%BaO;1%SrO;8%B 2 o 3 ;1%Al 2 o 3 ;0.5%TiO 2 ;11%K 2 O+Na 2 O; 1%Li 2 O; 1.5%CuO; The manufacturing process of glass colored glaze is as follows:

[0083] Put all the raw materials weighed into a ball mill and ball mill for 20 minutes at a speed of 80 rpm, and mix well;

[0084] Melt the obtained mixture at 1300°C to completely melt the mixture to obtain molten glass;

[0085] The molten glass liquid is water-quenched, and the glass frit after water-quenching is put into a ball mill for ball milling for 4 hours, and its rotating speed is 100 rpm to obtain glass powder;

[0086] The ball-milled glass powder is dried in a drying oven at 120°C, and the obtained powder is copper red glass glaze.

[0087] The prepared copper-red glass glaze and the blending agent are prepared into gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com