Disposal method of organic silicon copper-containing waste catalyst

A technology for waste catalysts and disposal methods, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of high temperature energy consumption in smelting methods, deactivation of waste catalysts, and difficulty in containing acid, and achieve good operability. And the effect of economy, short process flow and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

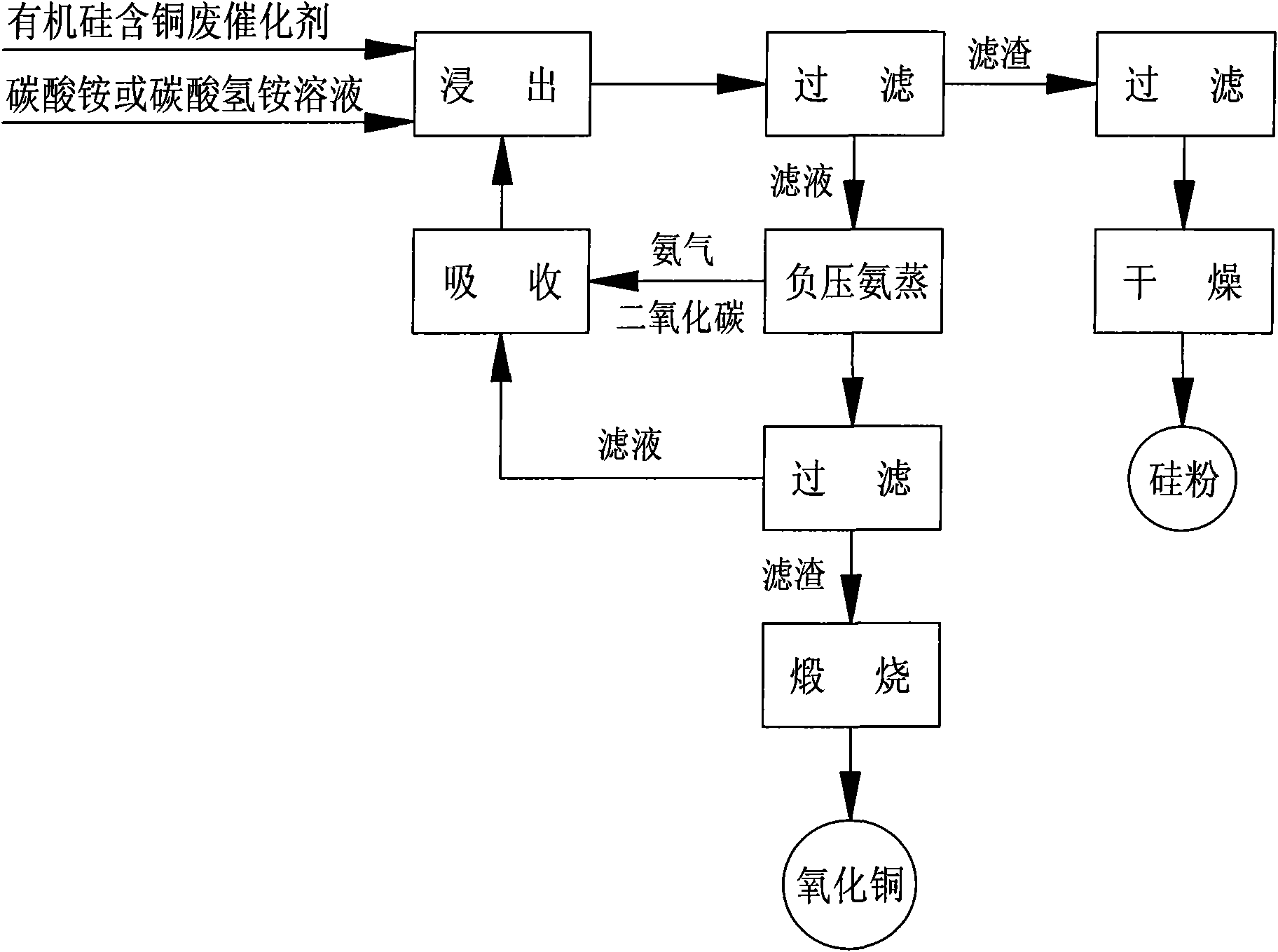

Method used

Image

Examples

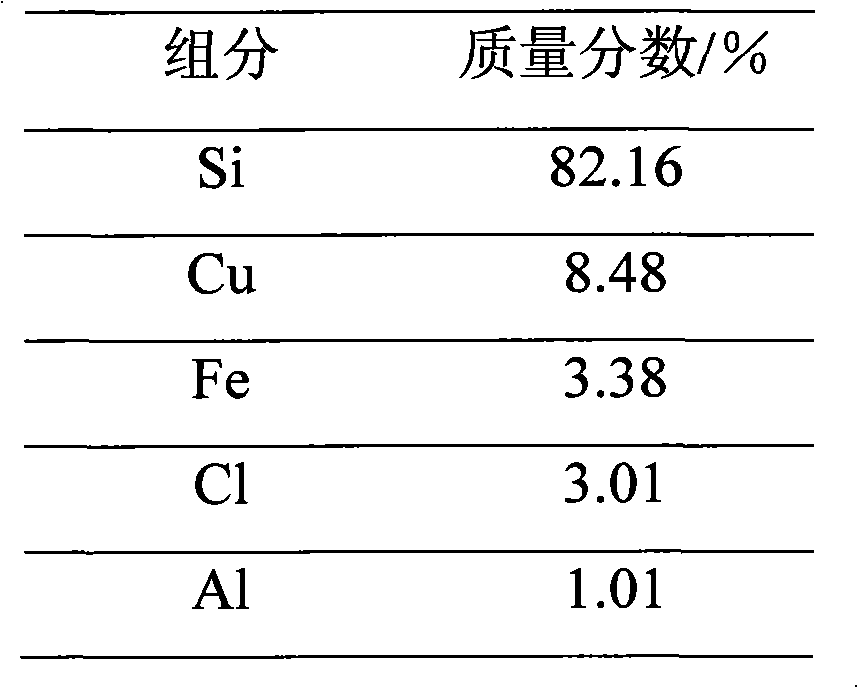

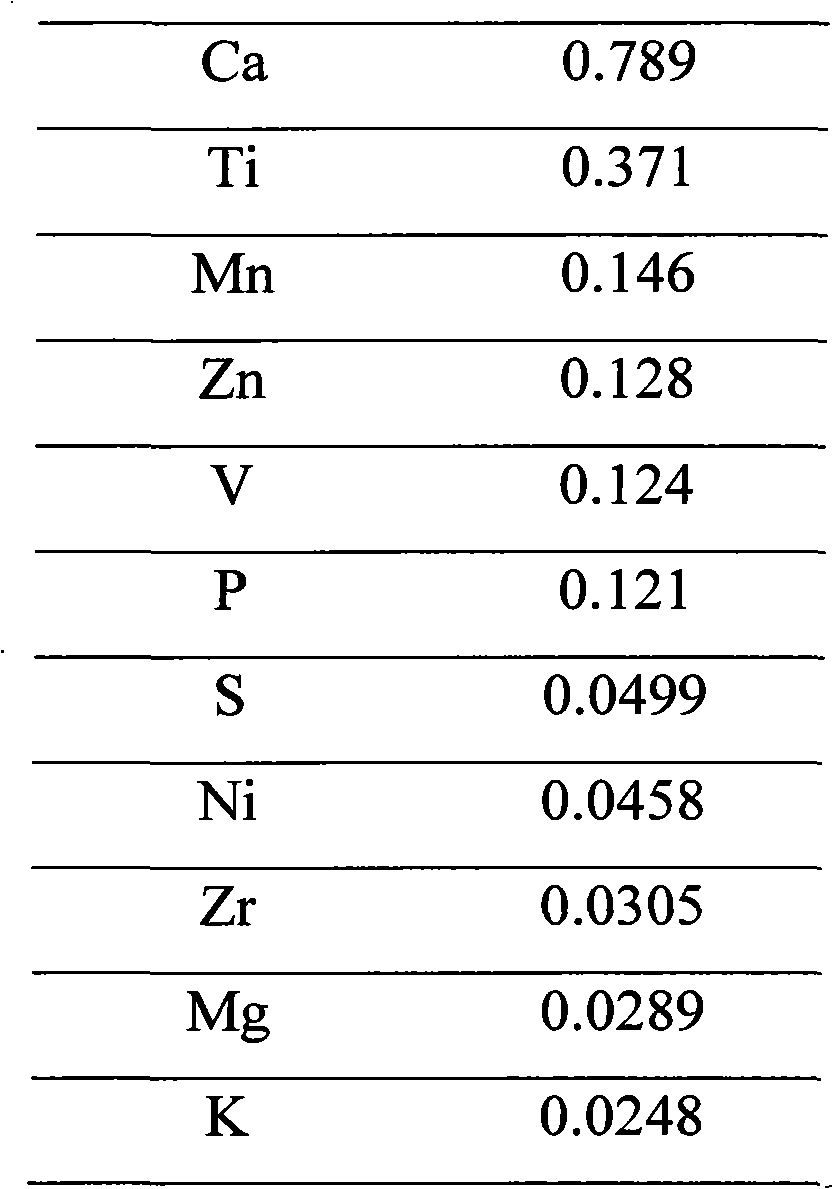

Embodiment 1

[0029] 1 ton of organic copper-containing waste catalyst is pulverized in a pulverizer, and then immersed in a leaching kettle filled with 4 tons of ammonium carbonate solution with a concentration of 1.2 mol / liter, and the solution in the leaching kettle is constantly stirred, and the leaching kettle The temperature of the solution is controlled at 40 degrees, soaked for 8 hours, the centrifuge is used to separate the leaching liquid from solid to liquid, and the separated solid phase is cleaned and dried to form a silicon-containing raw material (silicon powder). The solution is introduced into a distillation kettle with a pressure of 0.2Mpa to carry out negative pressure ammonia distillation for 4 hours, and absorb the ammonia and carbon dioxide produced in the process of negative pressure ammonia distillation with water; filter the solution obtained after negative pressure ammonia distillation, filter 80 kilograms of the filter residue that obtains afterward, wherein contai...

Embodiment 2

[0031] 1 ton of organic copper-containing waste catalyst is pulverized in a pulverizer, and then immersed in a leaching kettle filled with 5 tons of ammonium carbonate solution with a concentration of 1.25 mol / liter, and the solution in the leaching kettle is continuously stirred, and the leaching kettle The temperature of the solution is controlled at 50 degrees, soaked for 6 hours, the leachate is separated from the solid and liquid by a centrifuge, the separated solid phase is cleaned and dried to form a silicon-containing raw material (silicon powder), and the separated copper ammonia The solution is introduced into a distillation kettle with a pressure of 0.3Mpa to carry out negative pressure ammonia distillation for 3 hours, and absorb the ammonia and carbon dioxide produced in the process of negative pressure ammonia distillation with water; the solution obtained after negative pressure ammonia distillation is filtered and filtered 82 kilograms of the filter residue that...

Embodiment 3

[0033] 1 ton of organic copper-containing waste catalyst is pulverized in a pulverizer, then immersed in a leaching kettle filled with 6 tons of ammonium carbonate solution with a concentration of 2 mol / liter, and the solution in the leaching kettle is constantly stirred, and the leaching kettle The temperature of the solution is controlled at 60 degrees, soaked for 4 hours, the leachate is separated from the solid and liquid by a centrifuge, and the separated solid phase is cleaned and dried to form a silicon-containing raw material (silicon powder). The solution is introduced into a distillation kettle with a pressure of 0.4Mpa to carry out negative pressure ammonia distillation for 2 hours, and absorb the ammonia and carbon dioxide produced in the process of negative pressure ammonia distillation with water; filter the solution obtained after negative pressure ammonia distillation, filter 84 kilograms of the filter residue that obtains afterward, wherein contain basic copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com