Liquid crystal display

A liquid crystal display and liquid crystal display panel technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problem of adjacent pixel pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

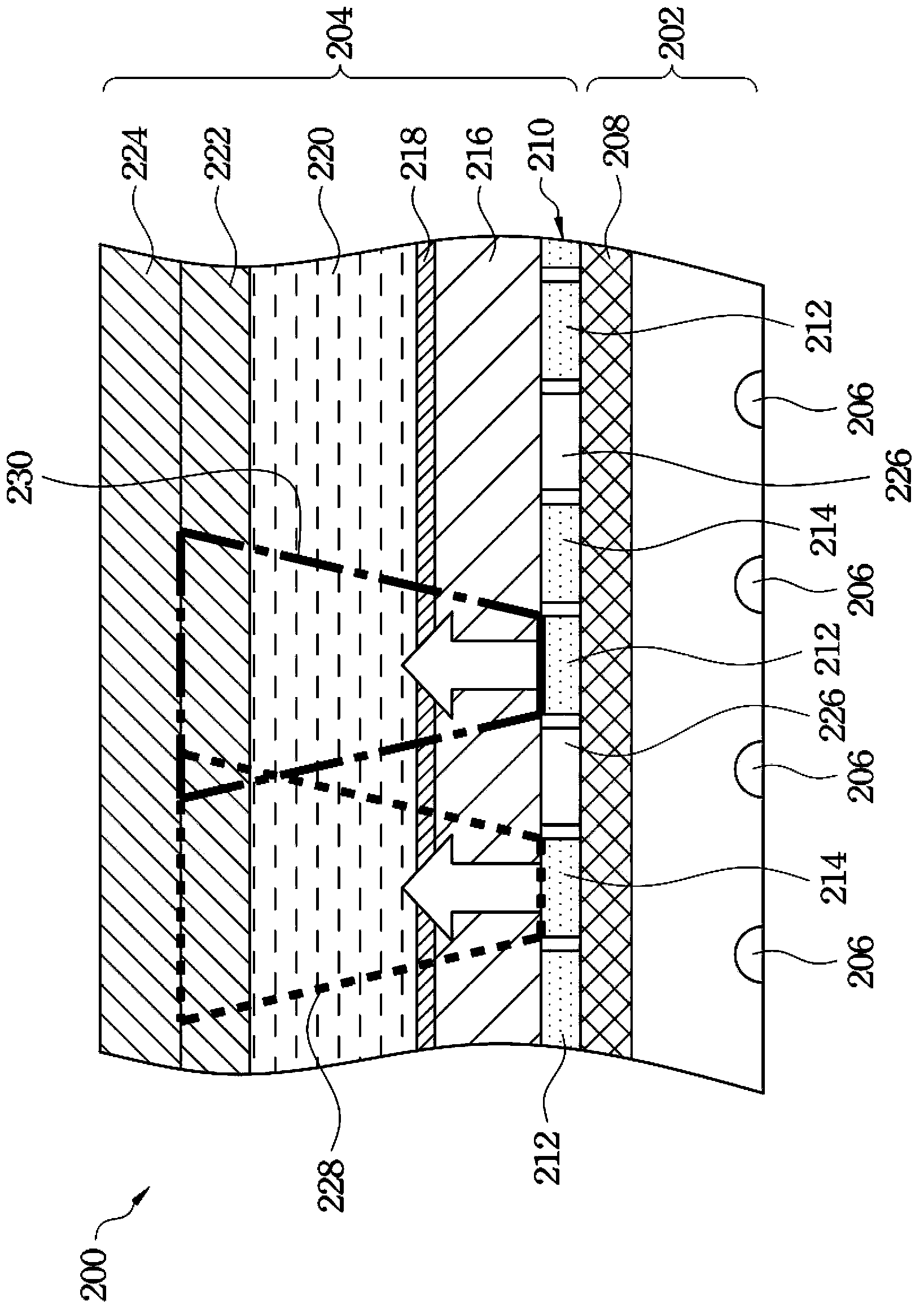

[0037] Please refer again figure 2, in order to prevent adjacent pixels of the liquid crystal display 200 from being polluted by red light or green light, the inventor proposes a solution of disposing a color filter (not shown) above the liquid crystal layer 220 . Use this color filter to filter out unnecessary colored light in pixels. However, the inventor believes that under the structure of the liquid crystal display 200, the thickness of the phosphor layer 210 should not be large, and there will be spaces between the particles of the phosphor, so that the blue light is likely to be emitted from the phosphor. These spaces of layer 210 are scattered out. Therefore, when the blue light passing through the red phosphor region 212 and the green phosphor region 214 is not completely absorbed, but part of the blue light passes through the phosphor layer 210 and exits, the red phosphor region 212 and the green phosphor The color of the light generated after the region 214 is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com