Colored concrete as well as preparation method and application method thereof

A technology of colored concrete and white cement, applied in the field of concrete, can solve the problems of no-suggestion, and achieve the effects of high durability, uniform color distribution, and improved durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The preparation method of colored concrete is as follows:

[0051] Step 1: Put white cement, fly ash, mineral powder, pigment, natural sand, crushed pebbles, slump retaining agent and polycarboxylate water reducer into their respective raw material bins for pre-homogenization;

[0052] Step 2: Carry out continuous batching according to weight ratio;

[0053] Step 3: Mix the prepared white cement, admixtures, pigments, coarse and fine aggregates in a forced mixer for 0.5-1 minute;

[0054]Step 4: Add water and admixture and stir for 0.5-1 minute to get colored concrete wet material.

[0055] The application method of colored concrete is as follows:

[0056] S1: After the colored concrete is poured, vibrate until the density is 2350-2450kg / cm 3 ;

[0057] S2: After finishing the vibration in S1, evenly brush a layer of protective agent on the surface of the colored concrete.

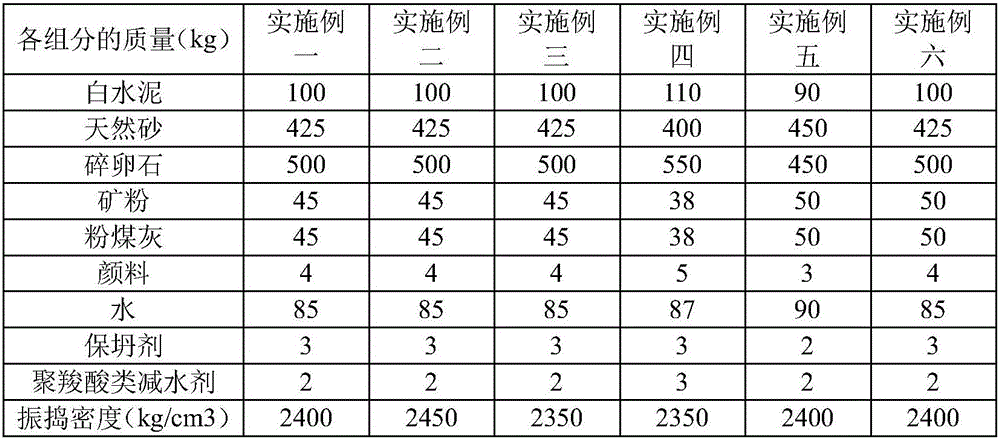

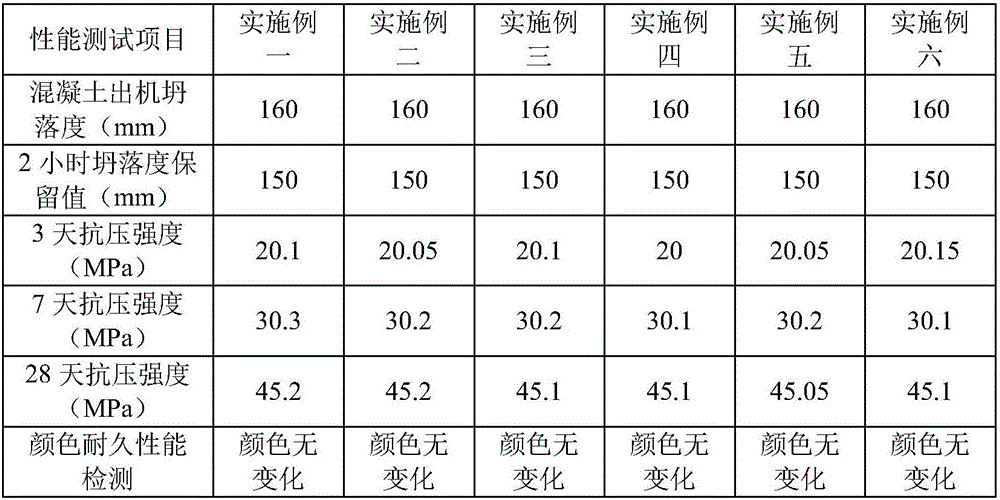

[0058] The difference of each embodiment is only that the quality of each component is diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com