Humidity controlling and drying method of banana slices using multi-mode ultrasound pretreatment

A technology of ultrasonic pretreatment and humidity control, which is applied in food ultrasonic treatment, food drying, preservation of fruits/vegetables through radiation/electrical treatment, etc. It can solve the problems of less research on pretreatment and achieve the effect of improving the drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

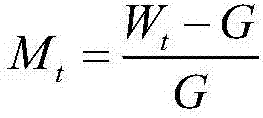

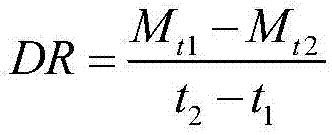

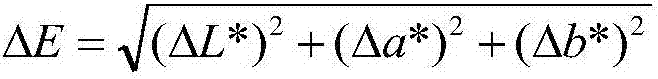

[0034] Pick five ripe fresh bananas of the same size, peel, devein, and slice. The slice thickness is 5±0.1mm. The ultrasonic mode is 60kHz, the power density is 150W / L, the ultrasonic pulse mode is 5s on, 5s off, and the ultrasonic pretreatment time for 30 minutes, and then carry out humidity-controlled drying, wherein the drying temperature is 80°C, and the relative humidity of the drying medium is 5%. Stop drying until the moisture content of the banana chips reaches 3-5%, and measure the maximum drying rate, rehydration rate and color change of the dried banana chips during the drying process. For the specific detection method, refer to Comparative Example 1.

Embodiment 2

[0036] Pick five ripe fresh bananas of the same size, peel, devein, and slice them. The thickness of the slices is 5±0.1mm. The ultrasonic mode is 40 / 60kHz. The power density of different ultrasonic frequencies is 150W / L. The pulse mode is to work for 5s, stop for 5s, ultrasonic pretreatment time is 15min, and then perform humidity-controlled drying, wherein the drying temperature is 80°C, and the relative humidity of the drying medium is 5%. Stop drying until the moisture content of the banana chips reaches 3-5%, and measure the maximum drying rate, rehydration rate and color change of the dried banana chips during the drying process. For the specific detection method, refer to Comparative Example 1.

Embodiment 3

[0038] Pick five ripe fresh bananas of the same size, peel, devein, and slice them. The thickness of the slices is 5±0.1mm. The ultrasonic mode is 20 / 40 / 60kHz. The power density of different ultrasonic frequencies is 150W / L. The ultrasonic working mode is synchronous. , the ultrasonic pulse mode is working for 5s, stopping for 5s, the ultrasonic pretreatment time is 10min, and then the humidity control drying is carried out, wherein the drying temperature is 80°C, and the relative humidity of the drying medium is 5%. Stop drying until the moisture content of the banana chips reaches 3-5%, and measure the maximum drying rate, rehydration rate and color change of the dried banana chips during the drying process. For the specific detection method, refer to Comparative Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com