Processing method for improving rehydration characteristics and reconstitution quality of dried shiitake mushrooms

A processing method and technology for dried shiitake mushrooms, which are applied in food drying, food science and other directions, can solve the problems of poor chewiness, loss of flavor and nutrients, and poor texture quality of rehydrated products, so as to promote the migration of water and reduce damage. effect of shortening the degree of drying and drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

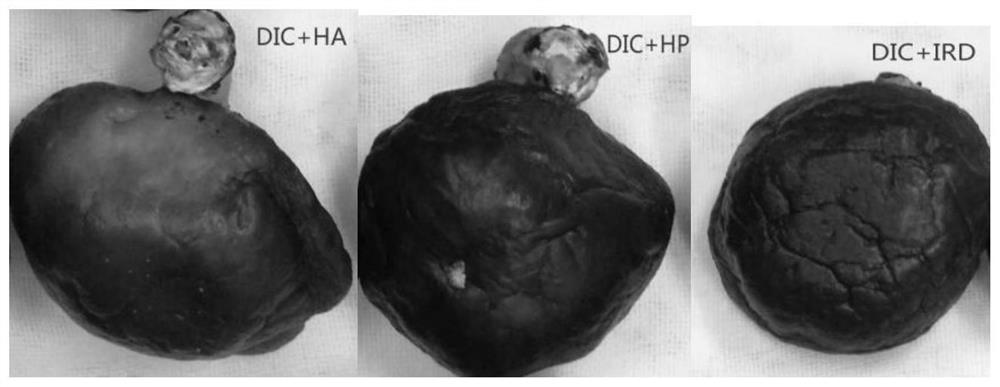

[0025] A processing technology that uses instantaneous high-temperature differential pressure flash steaming combined with low-temperature hot air drying to improve the rehydration characteristics and restoration quality of shiitake mushrooms. The process flow is as follows:

[0026] (1) Raw material processing: select intact mushrooms with a diameter of about 6 cm without mechanical damage, clean and remove the stems.

[0027] (2) Instantaneous high-temperature differential pressure drying: evenly lay the materials in step (1) on the tray of the instantaneous differential pressure treatment tank, the temperature is 95°C, the pressure is 0.8MPa, the heat preservation and pressure holding time is 20min, and the differential pressure treatment is 3 times; followed by vacuuming at 50 °C for 2.5 h to help fix the porous structure.

[0028] (3) Hot air drying: The sample after the instantaneous high temperature differential pressure treatment in step (2) is subjected to hot air dry...

Embodiment 2

[0031] The processing technology that utilizes instantaneous high-temperature differential pressure flash evaporation combined with low-temperature heat pump drying to improve the rehydration characteristics and restoration quality of shiitake mushrooms. The process flow is as follows:

[0032] (1) Raw material processing: select whole mushrooms without mechanical damage and about 6 cm in diameter, clean and remove the stems.

[0033] (2) Instantaneous high-temperature differential pressure drying: evenly lay the materials in step (1) on the tray of the instantaneous differential pressure treatment tank, the temperature is 95°C, the pressure is 0.8MPa, the heat preservation and pressure holding time is 20min, and the differential pressure treatment is 3 times; followed by vacuuming at 50 °C for 2.5 h to help fix the porous structure.

[0034] (3) Heat pump drying: heat pump drying is carried out on the sample after the instantaneous high temperature differential pressure dryin...

Embodiment 3

[0037] The processing technology that uses instantaneous high-temperature differential pressure flash steaming combined with low-temperature, medium-short-wave infrared drying to improve the rehydration characteristics and restoration quality of shiitake mushrooms. The process flow is as follows:

[0038] (1) Raw material processing: select whole mushrooms without mechanical damage and about 6 cm in diameter, clean and remove the stems.

[0039] (2) Instantaneous high-temperature differential pressure drying: evenly lay the materials in step (1) on the tray of the instantaneous differential pressure treatment tank, the temperature is 95°C, the pressure is 0.8MPa, the heat preservation and pressure holding time is 20min, and the differential pressure treatment is 3 times; followed by vacuuming at 50 °C for 2.5 h to help fix the porous structure.

[0040] (3) Medium-short wave infrared drying: The sample after the instantaneous high-temperature pressure difference drying in step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com