Production line and production technology for preparing river snail rice noodles

A production process, the technology of snail rice noodles, which is applied in the field of modulation snail rice noodles production line and its production technology, can solve the problems of not being able to meet the taste requirements of the public, unreasonable design of snail rice noodles, poor drying effect of production equipment, etc., and achieve controlled rehydration High efficiency, high rehydration rate, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

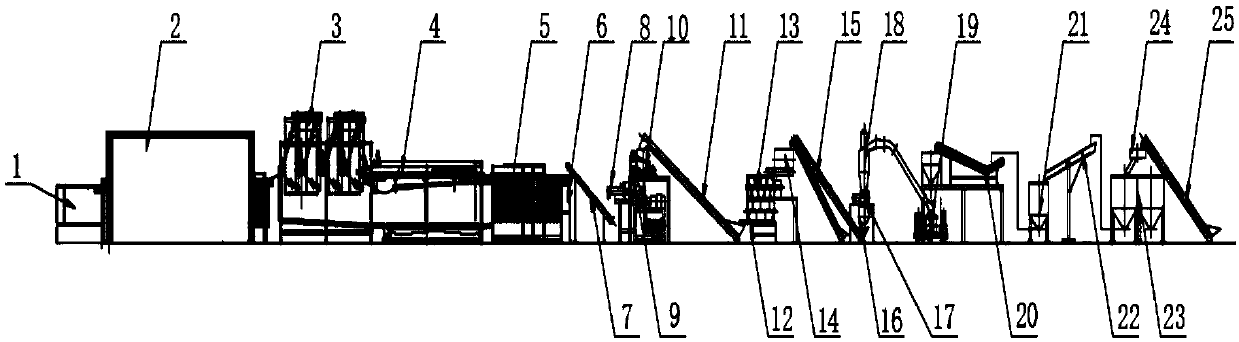

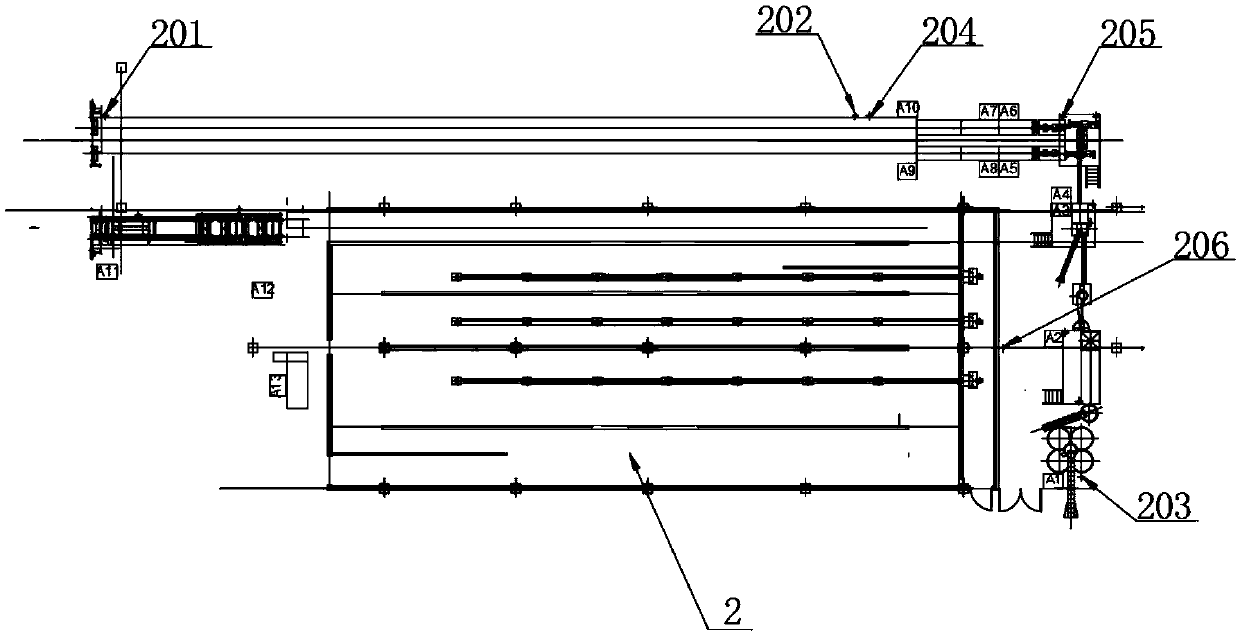

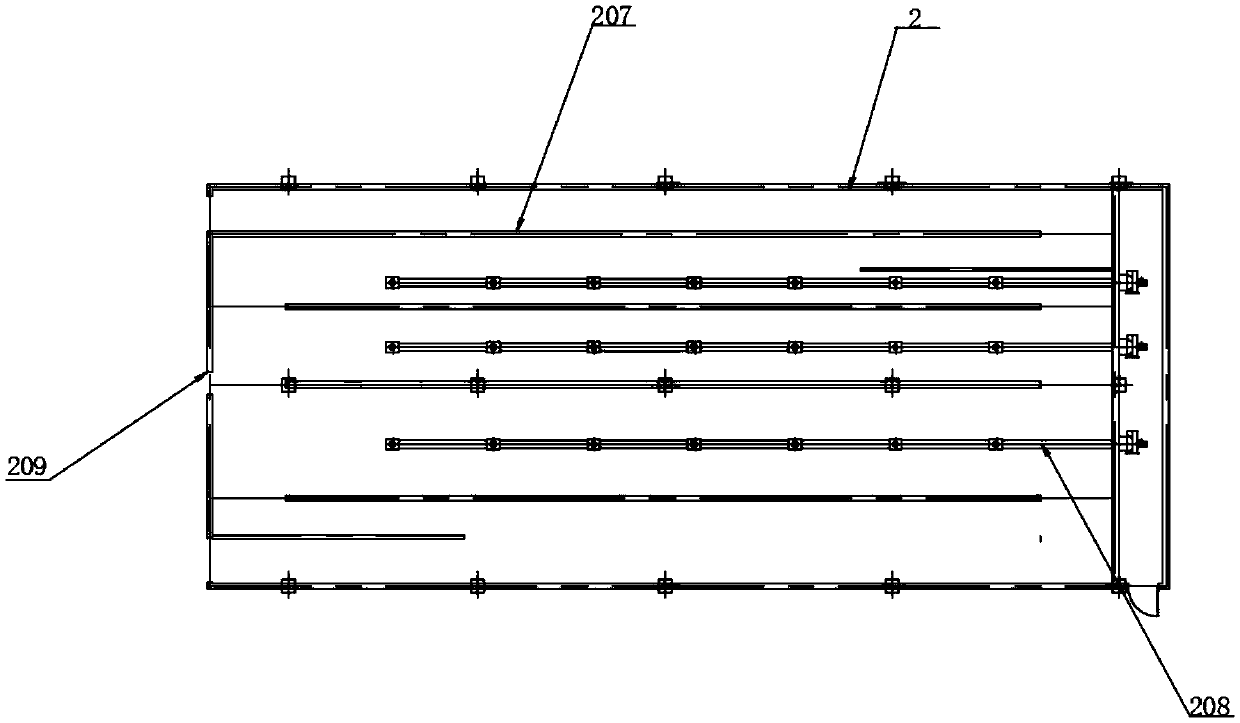

[0030] see Figure 1~4, in the embodiment of the present invention, a kind of modulation snail rice noodle production line and production technology thereof, comprise automatic drop rod cutting machine 1, one side of automatic drop rod cutting machine 1 is horizontally provided with drier 2, and the outside of drier 2 is respectively provided with The first compressed air pipe 201 and the first water inlet pipe 202, the first air inlet pipe 204, one end of the first compressed air pipe 201 is fixedly connected with the second compressed air pipe 206, and one end of the first water inlet pipe 202 is fixedly connected with the second inlet pipe. One end of the water pipe 203 and the first air inlet pipe 204 is fixedly connected with the second air inlet pipe 205. The inside of the dryer 2 is symmetrically provided with two first door openings 208. The height of the first door opening 208 is 3m and the width is 3m. There is a second door opening 209 at the middle position on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com