Freeze dried jackfruit pulp tablets and preparation method of tablets

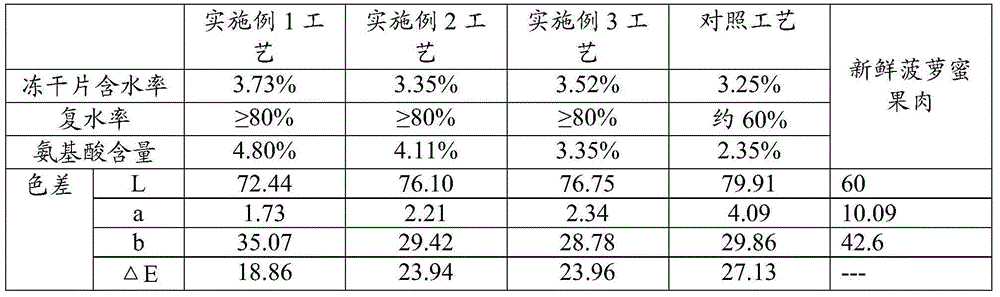

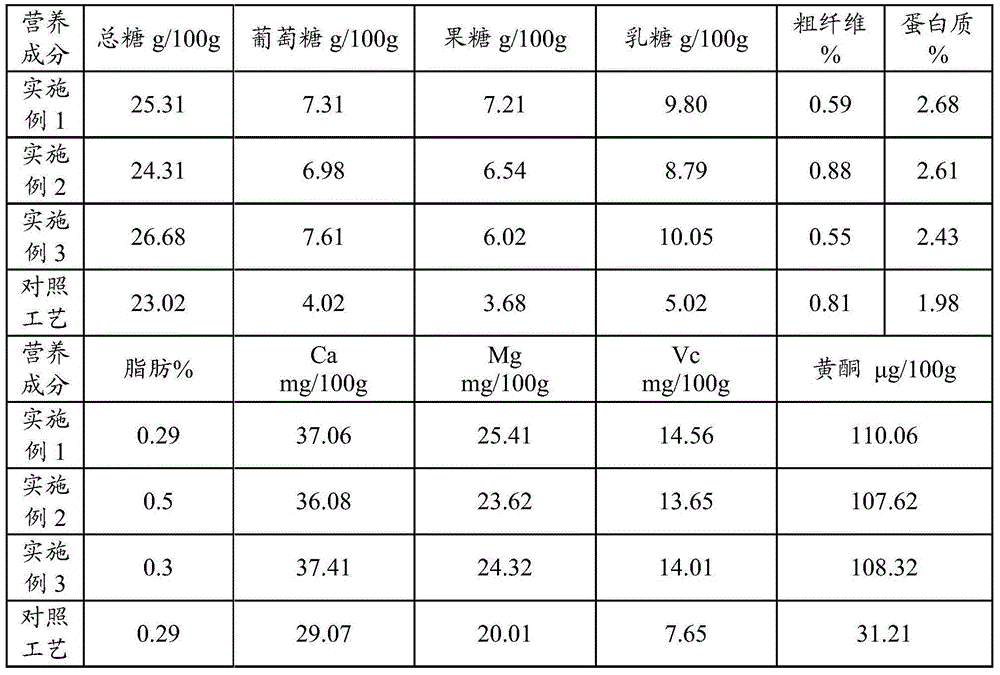

A technology for jackfruit and freeze-dried tablets, applied in the field of food processing, can solve the problems of low amino acid content, unsatisfactory effect, and low rehydration rate, and achieve the effects of high amino acid content, reduced energy consumption, and high rehydration rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: preparation method of the present invention

[0028] Select high-quality and ripe Malaysia No. 1 jackfruit, cut the peel, remove the shredded fruit and remove the seeds. Cut open the selected fresh jackfruit pulp, rinse and clean it with clean water, and then use 50ppm-100ppm sodium hypochlorite disinfectant to soak for disinfection and sterilization. After soaking, take it out and rinse it with clean water until there is no residual disinfectant on the surface. ,slice.

[0029] The treated jackfruit pulp was placed in a -20°C freezer for 24 hours, and the prefrozen jackfruit pulp was placed in a vacuum freeze-drying device with a vacuum degree of 30 Pa and a cooling temperature of -40°C. Vacuum freeze-drying is divided into three stages, the first stage is dried at a temperature of 50°C for 9 hours; the second stage is dried at a temperature of 45°C for 5 hours; the third stage is dried at a temperature of 40°C for 1 hour to obtain jackfruit Freeze-drie...

Embodiment 2

[0030] Embodiment 2: preparation method of the present invention

[0031] Select high-quality and ripe Malaysia No. 1 jackfruit, cut the peel, remove the shredded fruit and remove the seeds. Cut open the selected fresh jackfruit pulp, rinse and clean it with clean water, and then use 50ppm-100ppm sodium hypochlorite disinfectant to soak for disinfection and sterilization. After soaking, take it out and rinse it with clean water until there is no residual disinfectant on the surface. ,slice.

[0032] The processed jackfruit pulp was placed in a -30°C freezer for 2 hours for pre-freezing, and the pre-frozen jackfruit pulp was placed in a vacuum freeze-drying device with a vacuum degree of 40 Pa and a cooling temperature of -40°C. Vacuum freeze-drying is divided into three stages, the first stage is dried at 80°C for 10 hours; the second stage is dried at 70°C for 2 hours; the third stage is dried at 60°C for 3 hours to obtain jackfruit Freeze-dried pulp.

Embodiment 3

[0033] Embodiment 3: preparation method of the present invention

[0034] Select high-quality and ripe Malaysia No. 1 jackfruit, cut the peel, remove the shredded fruit and remove the seeds. Cut open the selected fresh jackfruit pulp, rinse and clean it with clean water, and then use 50ppm-100ppm sodium hypochlorite disinfectant to soak for disinfection and sterilization. After soaking, take it out and rinse it with clean water until there is no residual disinfectant on the surface. ,slice.

[0035] The processed jackfruit pulp was placed in a -10°C freezer for pre-freezing for 15 hours, and the pre-frozen jackfruit pulp was placed in a vacuum freeze-drying device with a vacuum degree of 50 Pa and a cooling temperature of -40°C. Vacuum freeze-drying is divided into three stages, the first stage is dried at 70°C for 11 hours; the second stage is dried at 60°C for 3 hours; the third stage is dried at 50°C for 2 hours to obtain jackfruit Freeze-dried pulp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com