Preparation method for fiber reinforced carbon-silicon carbide-zirconium carbide-based composite material

A fiber-reinforced, zirconium carbide-based technology is applied in the field of preparation of fiber-reinforced multiphase ceramic matrix composite materials, which can solve the problems of unfavorable industrialized production, high cost, long preparation period, etc., and achieves improved oxidation resistance and ablation resistance. , Conducive to industrialized production, the effect of shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

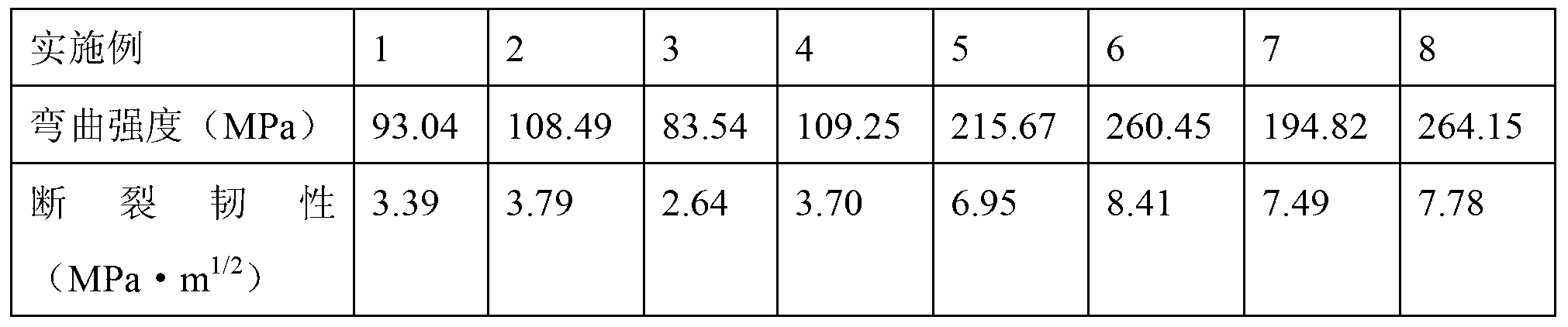

Examples

Embodiment 1

[0024] In this embodiment, the mass ratio of ZrC nano powder to phenolic resin is 0.02:1, and the selected two-dimensional carbon fiber cloth is two-dimensional T300 carbon fiber cloth. Its implementation method is carried out according to the following steps:

[0025] 1. Weigh 2 grams of ZrC nano powder (purity 99.0%, average particle size 50nm) on an analytical balance with an accuracy of 0.1 mg, weigh 80 grams of absolute ethanol on an ordinary balance, mix the two, stir evenly, and place Oscillation in the ultrasonic tank makes the ZrC nanometer powder dispersed evenly.

[0026] 2. After crushing the solid phenolic resin (properly crushing large pieces of resin), weigh 100 grams of resin and add it to the dispersion liquid prepared in step 1, place the mixed liquid in a 50°C oven and heat until the resin is completely dissolved, then Ultrasonic vibration is used to uniformly disperse the ZrC nanometer powder to form a slurry.

[0027] 3. After fully impregnating about 25...

Embodiment 2

[0031] The difference between this example and Example 1 is that the mass ratio of ZrC nano-powder to phenolic resin is 0.05:1 (ZrC nano-powder 5 grams), and the others are the same as Example 1.

Embodiment 3

[0033] The difference between this example and Example 1 is that the mass ratio of ZrC nano-powder to phenolic resin is 0.08:1 (ZrC nano-powder 8 grams), and the others are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com