Green oil silk-printing method for printed circuit board

A printed circuit board and silk screen printing technology, applied in printing, printing devices, etc., can solve problems such as green oil easily entering holes, affecting product performance and appearance, tin beads, etc., to prevent tin rings and tin beads hidden in holes , good electrical performance and appearance, the effect of good electrical performance and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The green oil screen printing method of embodiment 1PCB

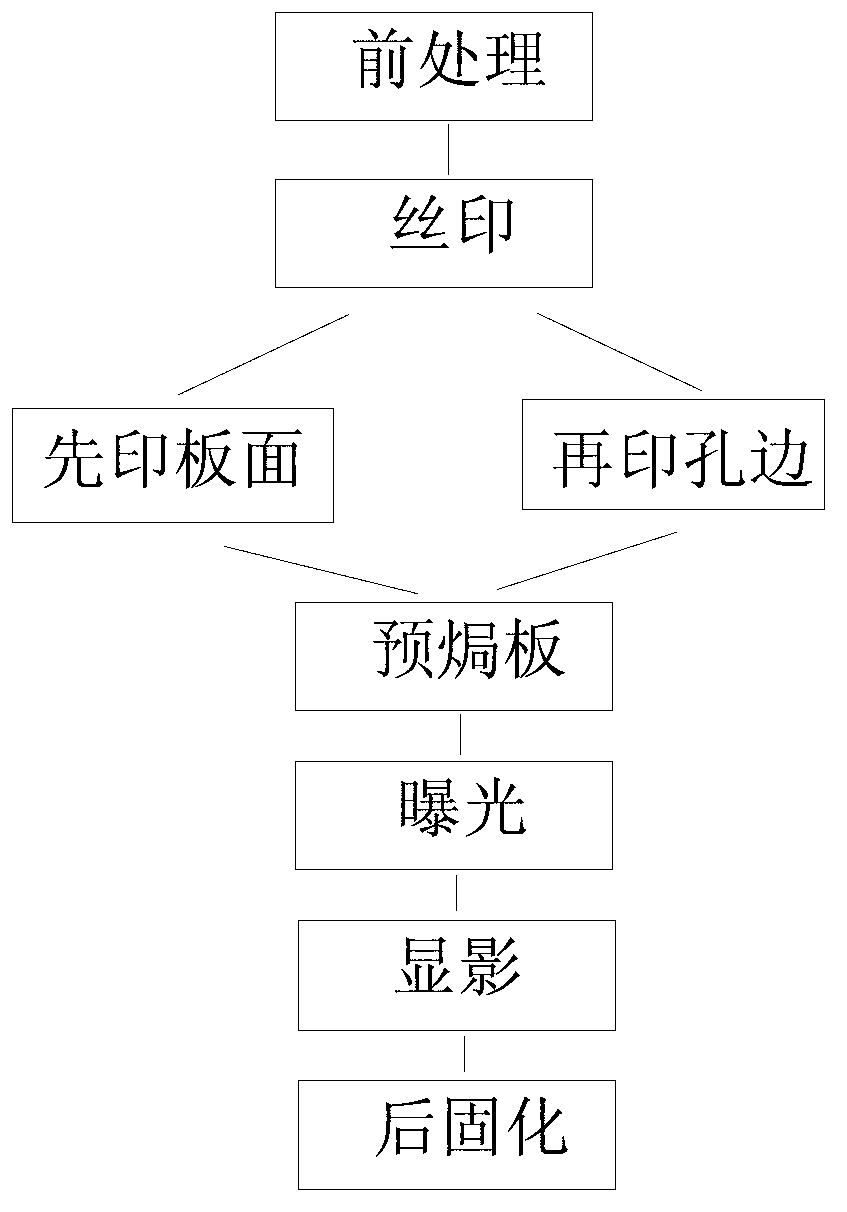

[0020] see Figure 1-3 As shown, a PCB circuit board green oil silk screen printing process aimed at small holes with green oil to cover oil and not plug holes, it includes the following processes: pre-treatment, silk screen, pre-baked board, exposure, development, post-curing, wherein the silk screen step Among them, the control parameters are: screen printing pressure 5kg / cm, screen printing speed 6m / min.

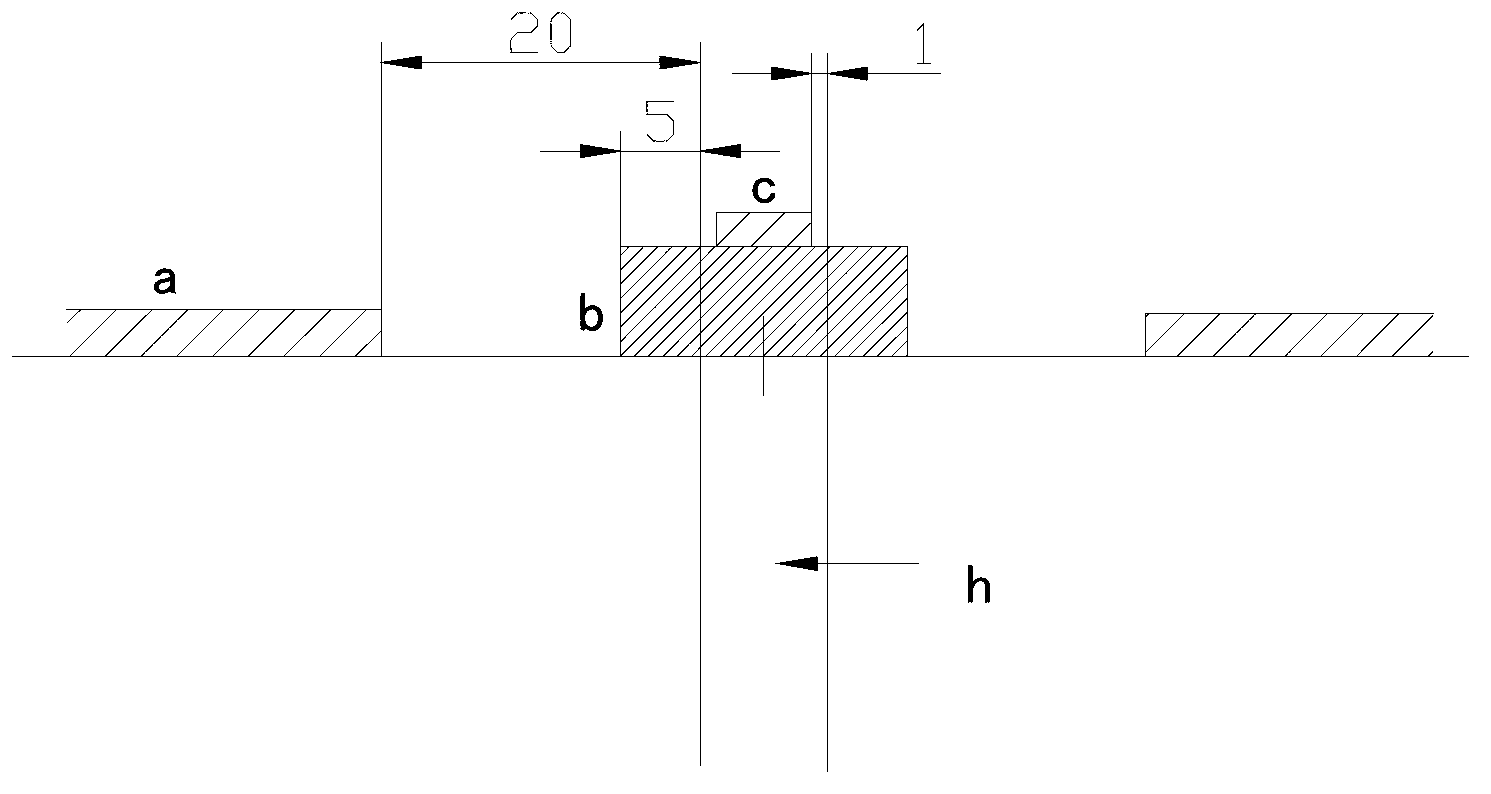

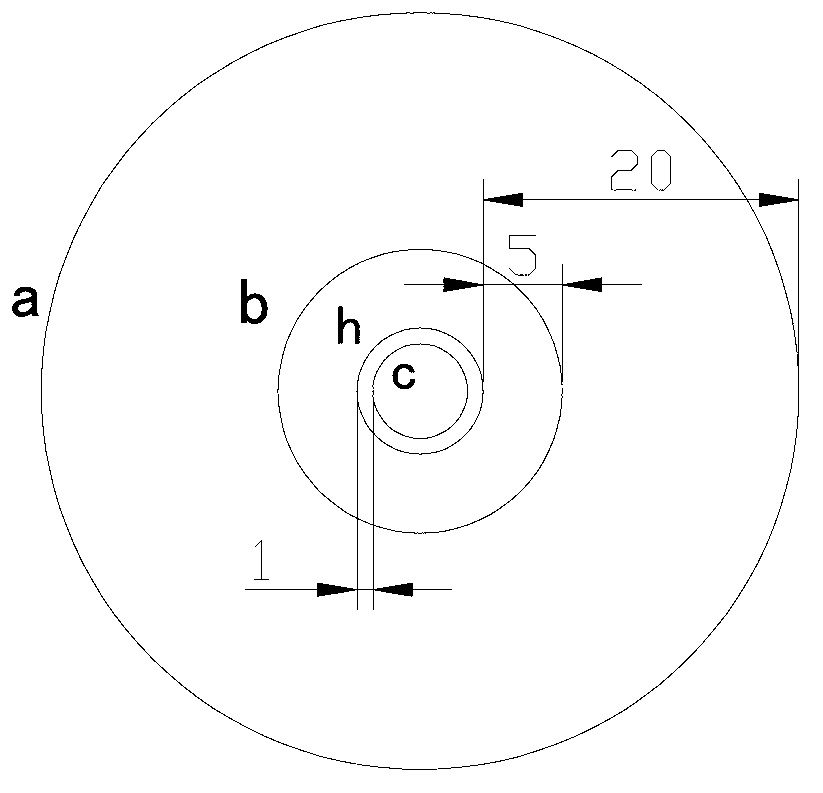

[0021] First, screen-print the board, the green oil viscosity is 110dps, preheat at 70°C for 45 minutes, and the mesh number of the screen-printed board is 36T / cm 2 ;The radius of the oil retaining PAD b corresponding to the drill hole h is 5mil larger than the radius of the drill hole h (Chinese is "mil", which is often used in PCB circuit boards, and its conversion unit is: 1mil=1 / 1000inch=0.00254cm);

[0022] Then screen-print the edge of the hole with a diameter of ≤0.4mm. The viscosity of the green oi...

Embodiment 2

[0026] The green oil screen printing method of embodiment 2PCB

[0027] Except that the green oil viscosity is 100dps when printing the board surface, preheat at 75°C for 45 minutes, and the mesh number of the screen printing drilling hole is 100T / cm 2 Except that other process parameters are all the same as in Example 1, the small hole green oil capping oil non-plugging silk screen printing method provided by this embodiment can well meet the quality requirements of production, and reduce the green oil plugging holes, dirty development, Bad defects such as tin rings on the edge of the hole after film printing and tin spraying, tin beads hidden in the hole, etc., make the PCB have good electrical performance and appearance, and the process of this method is simple and easy to operate, and the production efficiency is improved.

Embodiment 3

[0028] The green oil screen printing method of embodiment 3PCB

[0029] Except that the viscosity of the green oil is 120dps when printing the board surface, preheating at 65°C for 45 minutes, and the mesh number of the screen printing drilling hole is 110T / m 2 Except that other process parameters are all the same as in Example 1, the small hole green oil capping oil non-plugging silk screen printing method provided by this embodiment can well meet the quality requirements of production, and reduce the green oil plugging holes, dirty development, Bad defects such as tin rings on the edge of the hole after film printing and tin spraying, tin beads hidden in the hole, etc., make the PCB have good electrical performance and appearance, and the process of this method is simple and easy to operate, and the production efficiency is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com