Preparation method of1,5-naphthalene diisocyanate-based polyurethane microcellular elastomer

A technology of naphthalene diisocyanate and microporous elastomer, applied in 1 field, can solve the problems of high hardness, reduce other properties of products, affect product performance and service life, etc., and achieve the effect of expanding application scope and reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

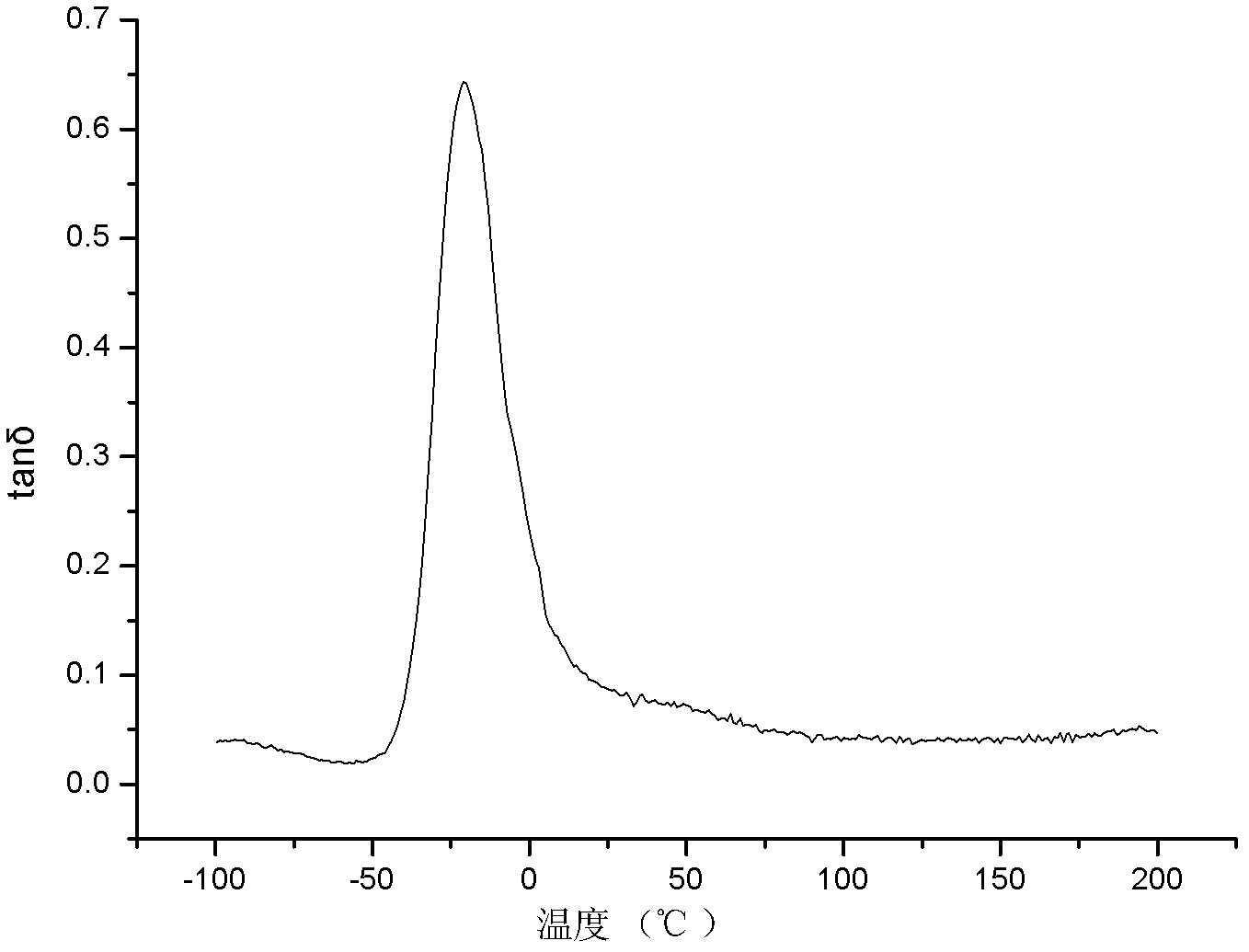

Image

Examples

Embodiment 1

[0036] 1000g molecular weight is 2000 polyadipate-butylene glycol ester and 286g NDI react 1h at 130 ℃ to obtain the prepolymer of-NCO%=5.64%; Chain extender component contains 20g 1,4-butanediol, 51g 4,4'-bis-sec-butylaminodiphenylmethane, 9g water, 10g composite catalyst, 15g surfactant; using a low-pressure foaming machine, mix the prepolymer and crosslinking agent according to the ratio of isocyanate index equal to 1 Components: inject the reaction material liquid into a mold at 80-110°C to manufacture microporous elastomer products, demould after 20-40 minutes, and then put it into an oven at 110°C for post-aging for 18 hours.

[0037] The product prepared according to this example was placed at room temperature for one week, and then its mechanical properties and hardness were measured.

[0038] Test mechanical properties with comparative example 1.

[0039] Test hardness with comparative example 1.

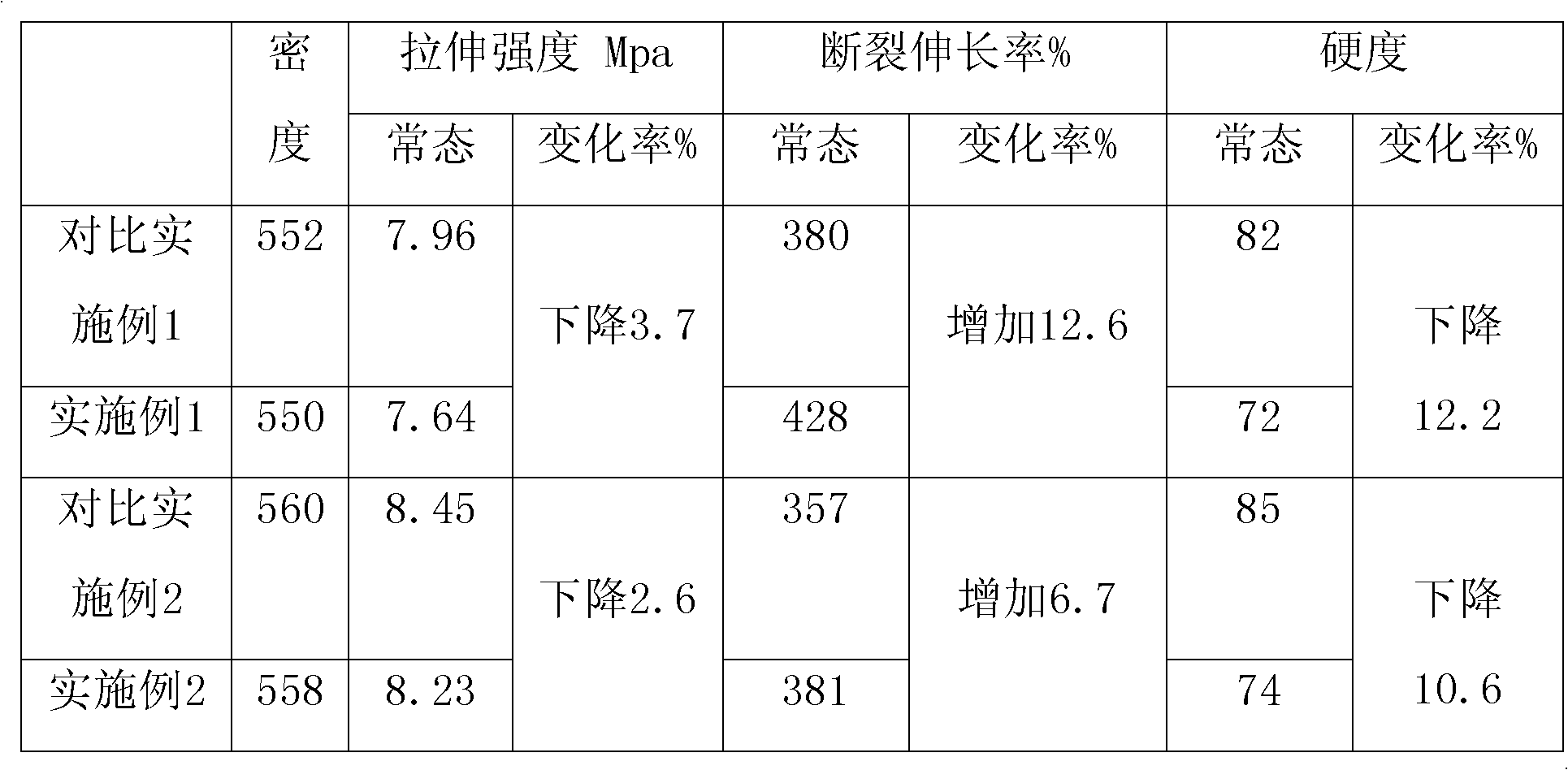

[0040] The test results are shown in Table 1.

Embodiment 2

[0042] 1000g of polyadipate-neopentyl glycol with a molecular weight of 2000 and 234g of NDI were reacted at 130°C for 1h to obtain a prepolymer with -NCO%=4.2%; the chain extender component contained 20g of 1,4-butanediol , 10g dimethylthiotoluenediamine, 9.25g N-N'di-sec-butyl-p-phenylenediamine, 5.4g water, 10g composite catalyst, 15g surfactant; using a low-pressure foaming machine, according to the isocyanate index is equal to 1 Mix the prepolymer and crosslinking agent components, inject the reaction material liquid into the mold at 80-110°C to make microporous elastomer products, demould after 20-40min, and then put it in an oven at 110°C for post-curing 18 hours.

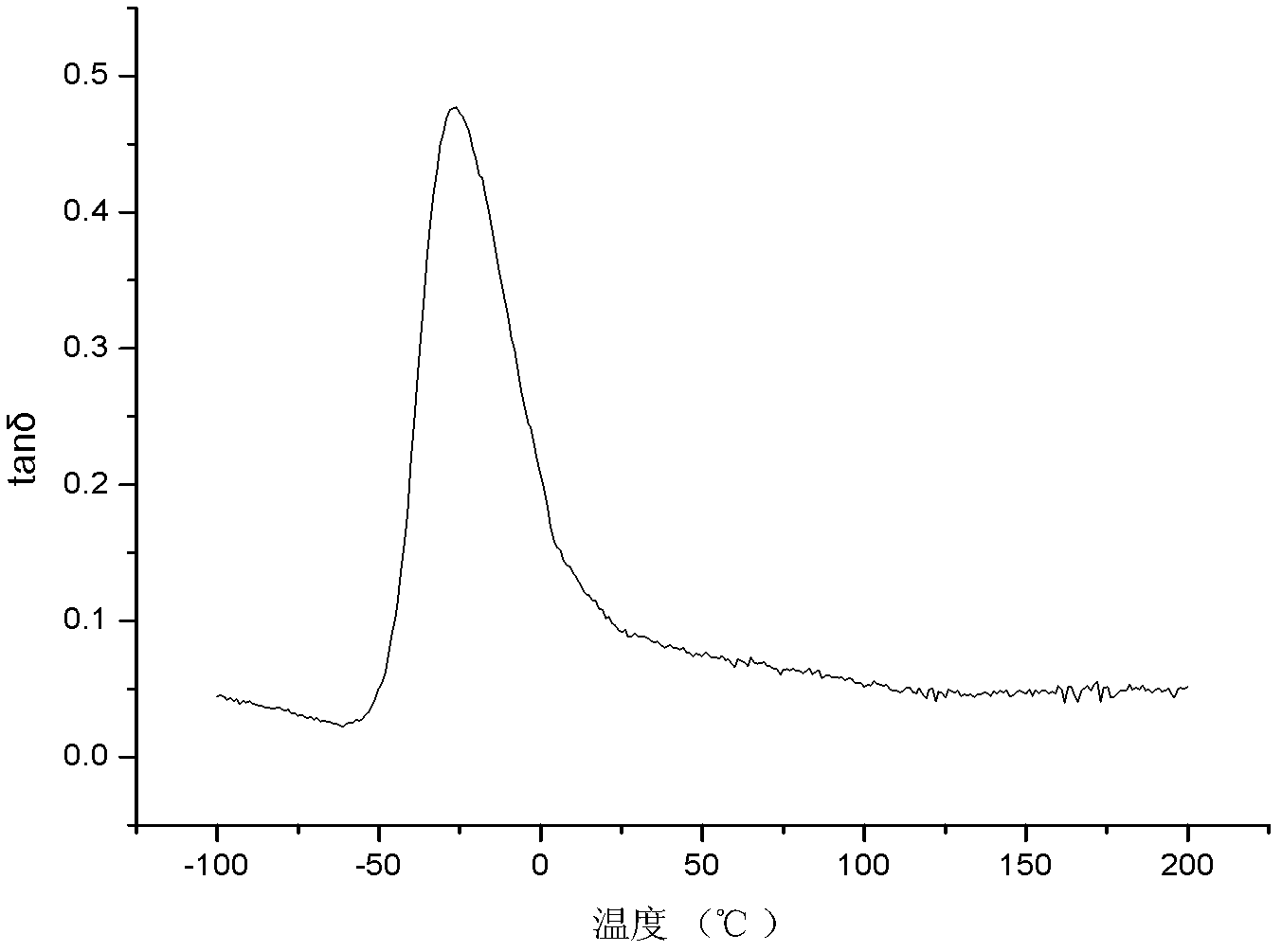

[0043] The product prepared according to this example was placed at room temperature for one week, and then its mechanical properties and hardness were measured.

[0044] Test mechanical properties with comparative example 1.

[0045] Test hardness with comparative example 1.

[0046] The test results are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com