Glass body of glass and method thereof

A glass cup and cup body technology, which is applied to water boiling utensils, cooking utensils, household utensils, etc., can solve the problems of high labor cost, aging and loose glue, and peculiar smell of glue, so as to achieve high production efficiency and extended service life. , The effect of less processing and production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

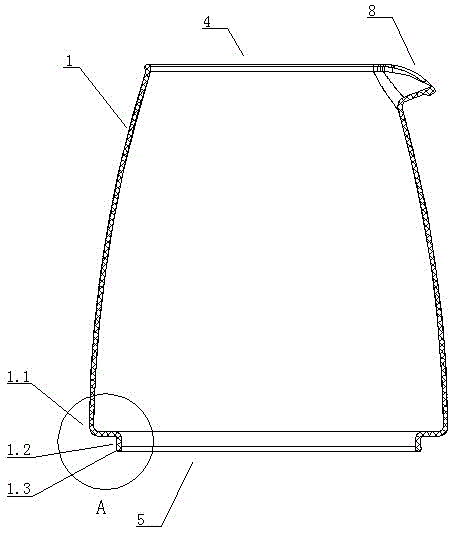

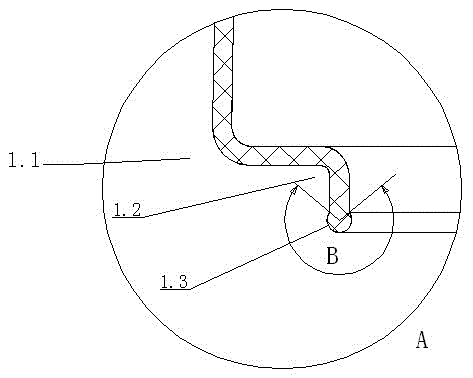

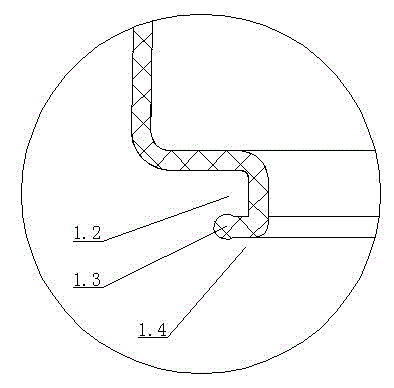

[0027] see Figure 1-Figure 7 , a glass cup body 1, comprising a cup body upper opening 4, a lower opening 5, a heating plate 3 arranged at the bottom of the glass cup body 1, a sealing ring 2 and a base 6, the upper opening 4 and the lower opening 5 of the cup body The rounded closing edge 1.3 is set, and the lower opening 5 junction of the heating plate 3 and the glass cup body 1 is provided with an annular sealing ring 2, and the sealing ring 2 is made of high temperature resistant, anti-aging elastic silica gel. The lower part of the glass cup body 1 is provided with an inwardly curved step portion 1.1 and an inner flange 1.2 connected to and arranged below the step portion 1.1. The lower opening 5 of the inner flange 1.2 is provided with a rounded closing edge 1.3, and the rounded closing edge 1.3 is set as Smooth curved surface, the lower opening 5 can be set as a rounded closing edge 1.3 downward; or the lower opening 5 can be set as a rounded closing edge 1.3 outward f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com