Glass kettle sealing and fixing structure and assembling method thereof

A sealed, fixed, glass technology, applied in water boiling utensils, heating devices, cooking utensils, etc., can solve the problems of external shape changes affected by structure, high production cost, not beautiful, and achieve beautiful appearance and production efficiency. High, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

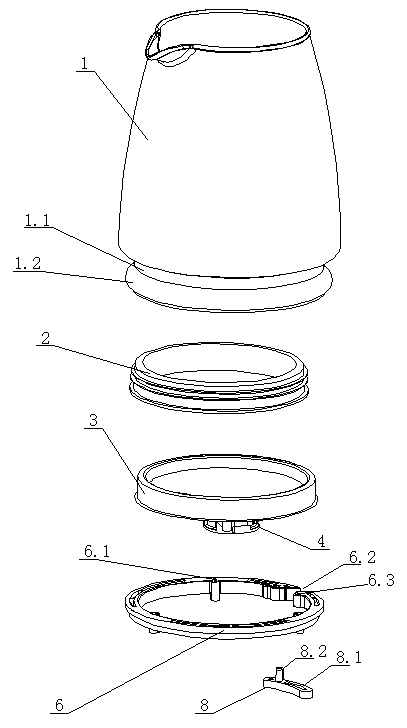

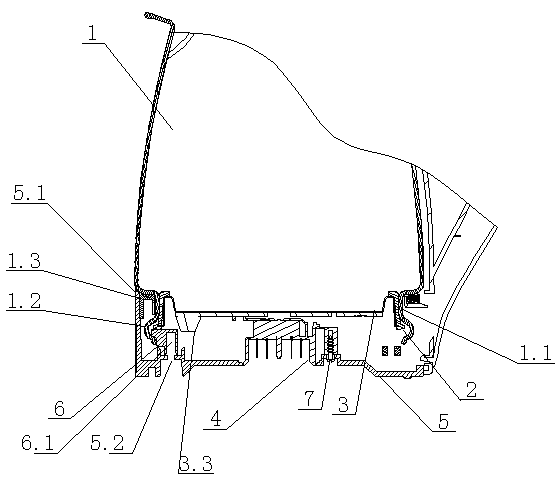

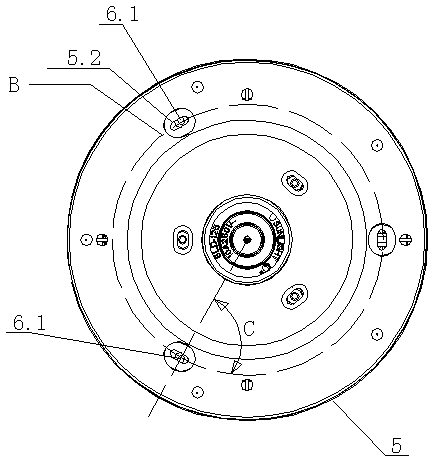

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0035] Examples see Figure 1-Figure 3 The difference between this embodiment and the first embodiment is that a fixing ring 6 is installed at the bottom of the heating plate 3 and the sealing ring 2 . Its assembly method includes the following steps:

[0036] 1) Stretch the sealing ring 2, put the heating plate 3 with the upper and lower ends of the circular structure into the sealing ring 2 under strong pressure;

[0037] 2) Gently bend the above components and put them into the stepped part 1.1 of the glass jug body 1 under strong pressure;

[0038] 3) Squeeze the opening of the fixed support ring 6; the diameter of the fixed support ring 6 shrinks and becomes smaller, enters the annular convex inner groove 1.2 of the glass pot body 1, places it on the bottom of the heating plate 3 and the sealing ring 2, and loosens the opening of the fixed support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com