Milk foam making kettle and method

A technology of milk foam and friction parts, which is applied in the fields of foaming containers, stirring, and liquid food heating. It can solve the problems of not being able to clean, not combining utensils, and inconvenient cleaning, etc., to achieve extended service life, high production efficiency, and sealing effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

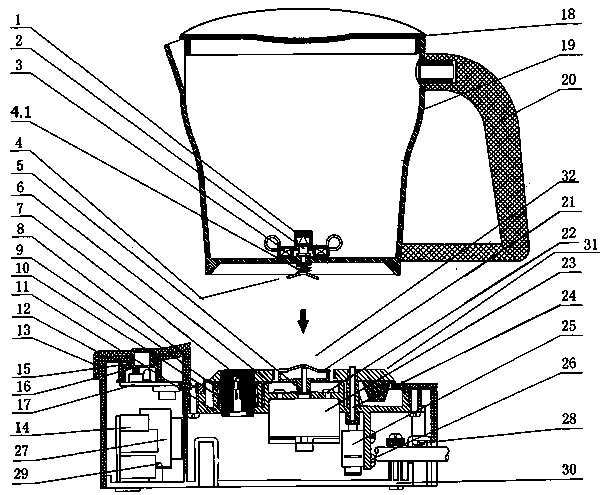

[0027] Such as figure 1 As shown, the main body of the milk frothing jug includes a container 19 and a heater 32. The upper part of the heater 32 is provided with a limiter 31 that can be inserted into the lower part of the container 19, and a rotatable The agitator 1, the heater 32 is provided with a transmission motor 23 that can drive the agitator 1, and the heater 32 is provided with a heater 6, a temperature control probe 7 and a micro switch 25 at the bottom surface of the limit position 31. The heater 32 described above is provided with a controller 14 electrically connected to the heater 6 , the temperature control probe 7 , the micro switch 25 and the transmission motor 23 . The container 19 is equipped with a handle 20, riveted with the stirring shaft 2, and the stirring shaft 2 is buckled with the stirrer 1, the elastic elastic friction part 4, the spring 4.1, the container mouth cover with the container cover 18; the heater is provided with the heater 6, Temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com