Medical stone and purple sand mixed mud pottery and preparation method thereof

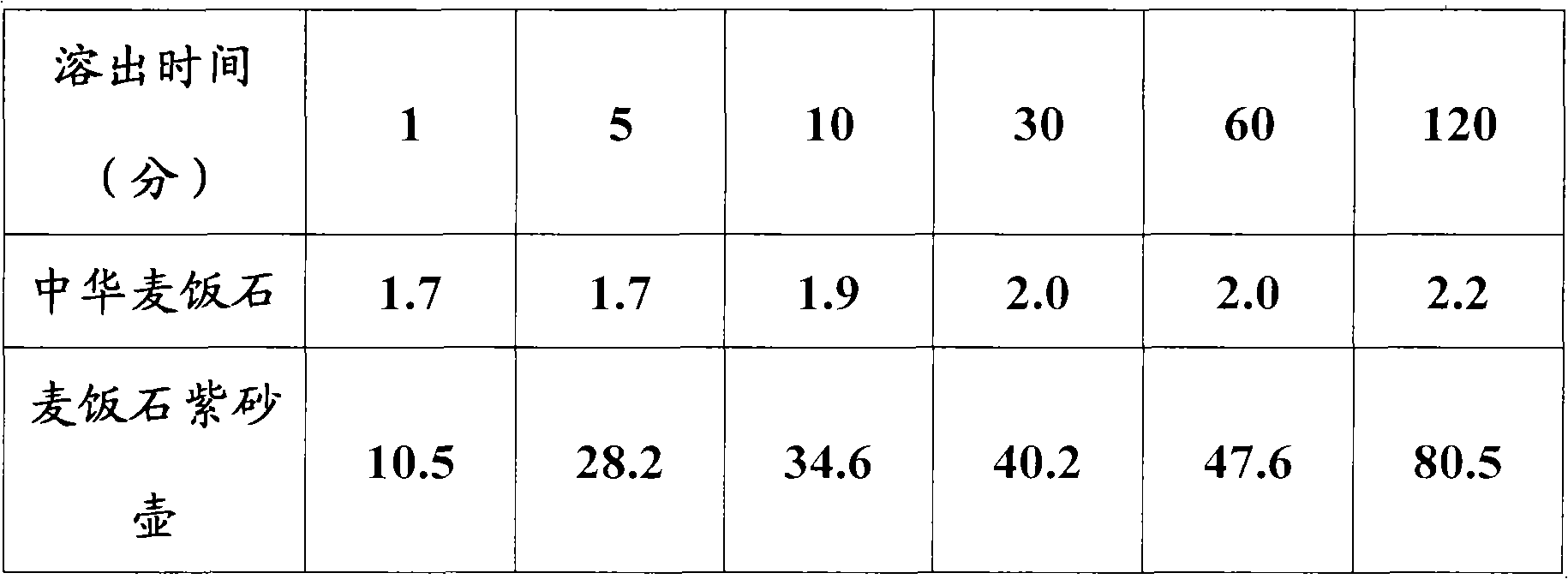

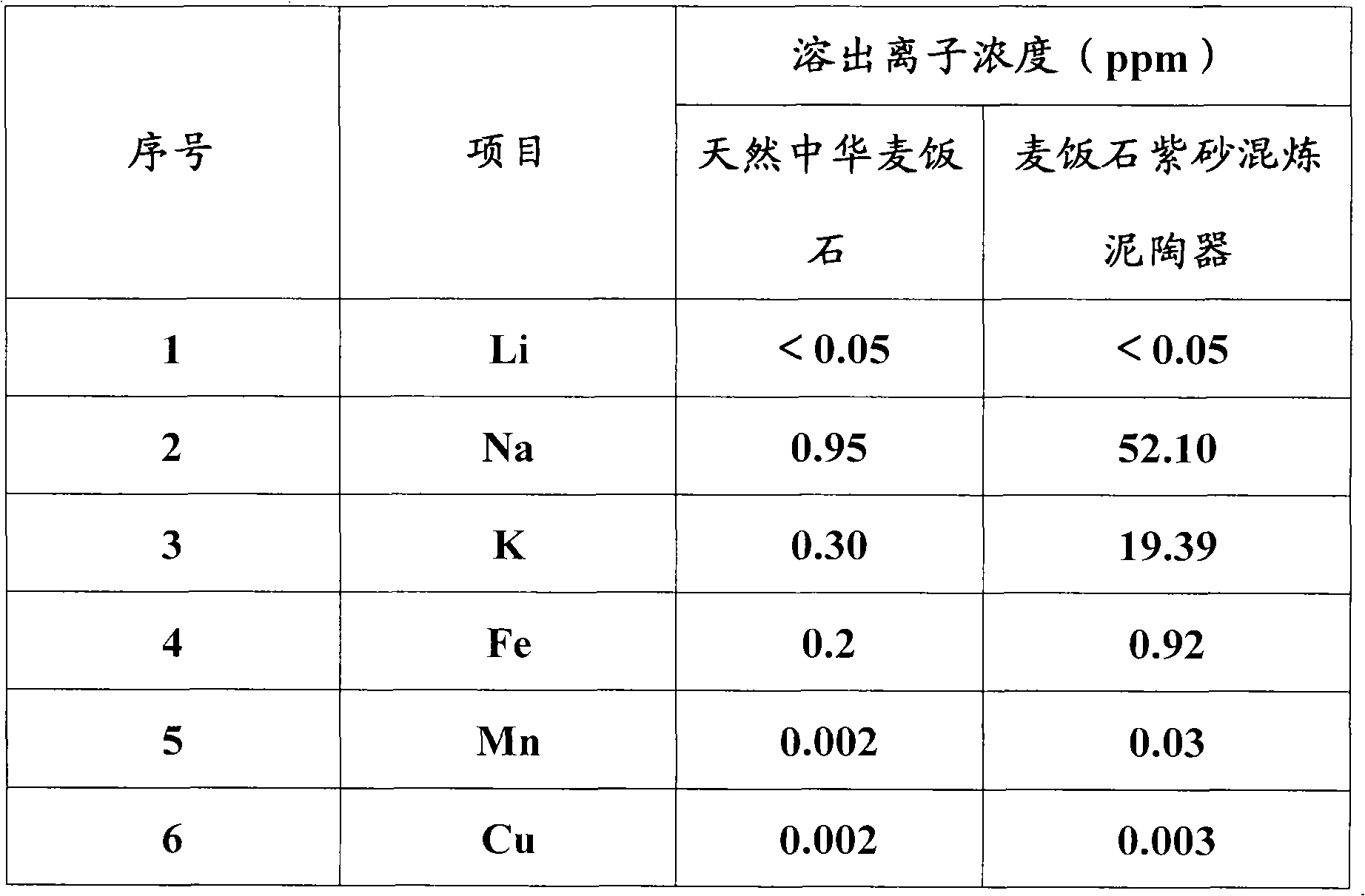

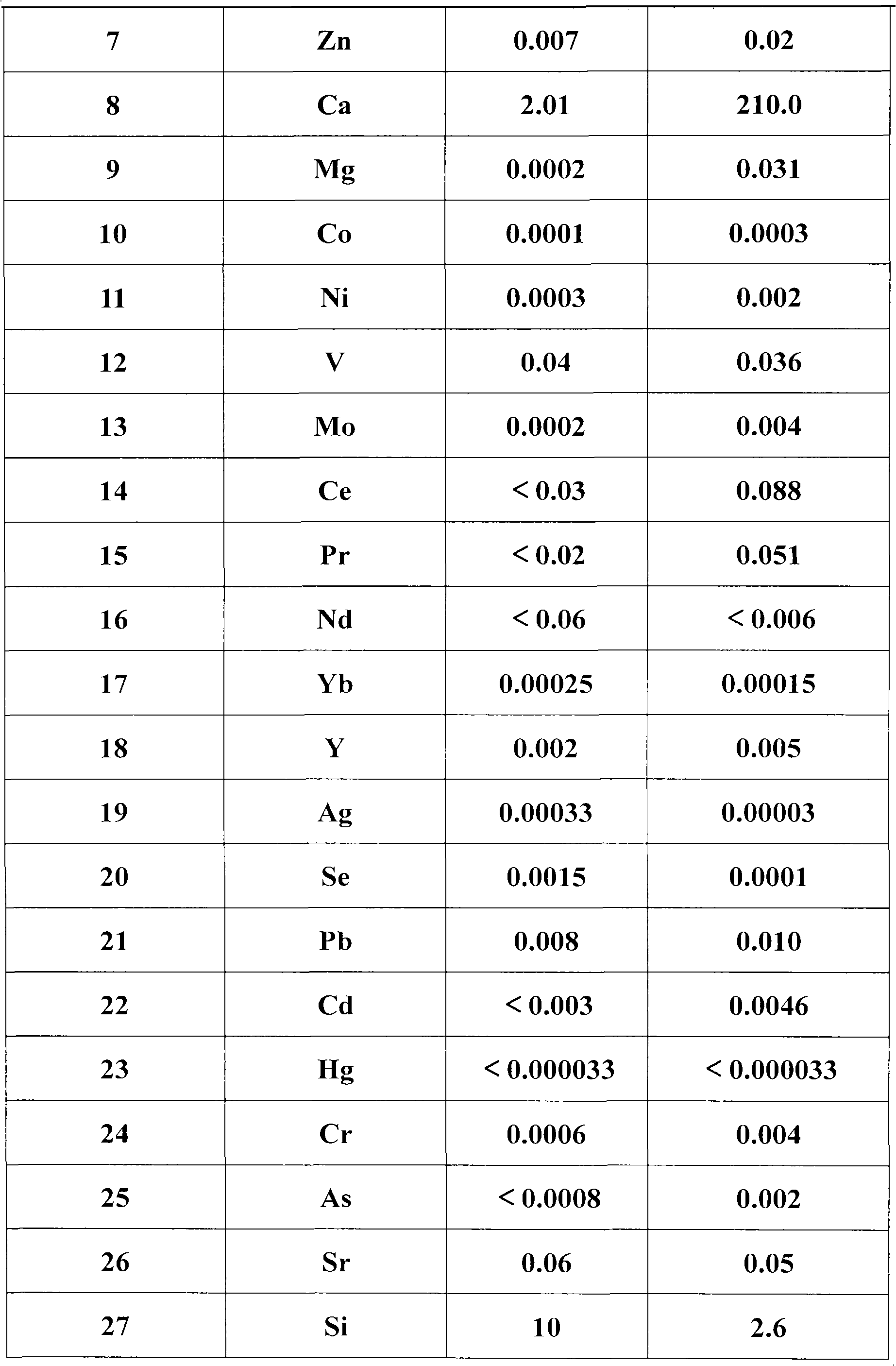

The technology of medical stone and purple sand is applied in the field of pottery and its preparation, which can solve the problems of difficult molding of utensils and unbeautiful surfaces, and achieve the effects of reducing the dissolution capacity, increasing the rate of dissolution ions, and enhancing the dissolution capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of this product is:

[0034] a. Mixing the natural medical stone with a particle size of 80-200 mesh in a ball mill pulverizer with the naturally stale purple sand in proportion, and grinding the mixture in a grinder or a stone mill to obtain a mixture powder;

[0035] b. Screen the ground and pulverized powder with a 40-mesh sieve, and remove the magnetite with a strong magnetic rod;

[0036] c. Add water to the mixture powder obtained after screening and iron removal, and use the elutriation method to remove mica flakes and some lighter debris suspended matter. The specific gravity of the mud is controlled below 1.7, and the filter method is used again with a strong magnetic Remove iron with a net, then blend evenly and soak in a vat for more than 24 hours;

[0037] d. Dry the soaked mud in a cylinder, beat it into mud or mechanically vacuum mud, seal and pack the refined mud, and make medical stone purple sand mixed mud;

[0038] e. Use medic...

Embodiment 1

[0046] The 100-mesh Chinese medical stone and 40% purple sand bottom groove blue mud that are respectively 50% by weight are pulverized into a mixture powder of 40-200 mesh size in a pulverizer, and the pulverized powder is screened with a 40-mesh sieve, and Remove the magnetite with a strong magnetic rod, add water to the obtained mixture powder, use the elutriation method to remove mica flakes and some lighter debris, impurity suspensions, and then mix 10% of the 50-mesh bottom tank green mud and gravel to mix evenly and lower the tank Soaking, the specific gravity of the mud should be controlled below 1.7, and the filter type should be used to remove iron again with a strong magnetic net, and the mud soaked for more than 24 hours will be dried in a cylinder, beaten into mud or mechanically hollowed into mud, and the refined mud will be sealed and packaged . Use the refined mud to make a blank by hand according to the purple sand molding process to make the green body of the...

Embodiment 2

[0057] 50% of the 80-120 mesh Chinese medical stone and 50% of the purple sand red brown mud are pulverized into a mixture powder of 40-200 mesh size in a pulverizer, and the pulverized powder is screened with a 40 mesh sieve. And use a strong magnetic rod to remove the magnetite, add water to the obtained mixture powder, use the elutriation method to remove mica flakes and some lighter debris, impurity suspended matter, and then blend evenly and soak in the tank. The specific gravity of the mud should be controlled at 1.7. Next, use the filter type to remove iron with a strong magnetic net again, dry the mud soaked for more than 24 hours, beat it into mud or mechanically hollow the mud, and seal the mud after refining. Use the refined mud to make a medical stone purple sand teapot by molding according to the purple sand molding process, and dry it naturally. After drying, the engraved green body is fired in an electric kiln at a temperature of 1150°C for 10 hours to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com