Assembly method of heating explosion-proof glass kettle

An assembly method and glass technology, applied in the direction of boiling water appliances and other directions, can solve the problems of hidden dangers, the glass body is easy to hit and burst, and achieve the effect of prolonging the service life, beautiful and elegant appearance, and good explosion-proof effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

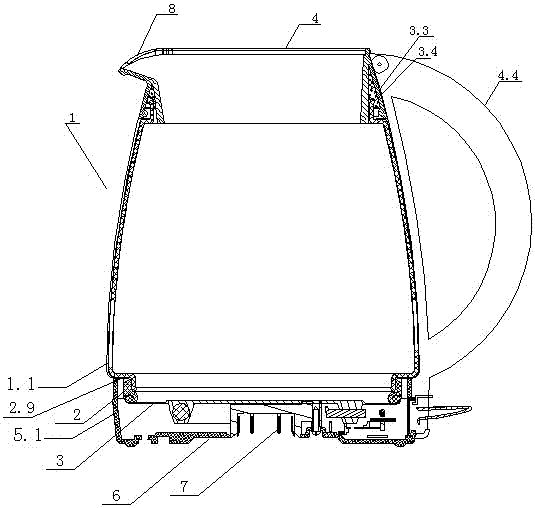

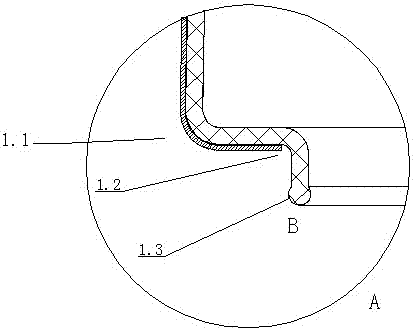

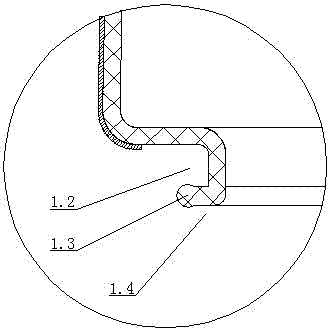

[0044] see Figure 1-Figure 8 , an assembly method 11 for heating an explosion-proof glass kettle, including an upper opening 4 of the cup body, a lower opening 5, a protective film 1.9, a shrinkage part or a spout part 3.3, a main body 1.6, a handle 4.4, glue 3.4, and is arranged on the glass body 11 bottom heating plate 3, sealing ring 2, fixed ring 2.9 and base 6, the upper opening 4 and the lower opening 5 of the cup body are provided with a rounded closing edge 1.3, and the lower opening 5 of the heating plate 3 and the glass cup body 11 is connected. An annular sealing ring 2 is arranged, and the sealing ring 2 is made of elastic silica gel with high temperature resistance and aging resistance. Heated explosion-proof glass cup body 1 is provided with a step 1.2 on the inner side of the upper opening 4 and the lower opening 5, and the step 1.2 is smoothly connected with the outside of the main body 1.6, and the bending part 2.0 between the step 1.2 and the main body 1.6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com