Patents

Literature

75results about How to "Churn fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-performance liquid chromatography separation and determination method for related impurities in fosfomycin trometamol raw material drug and preparations thereof and application thereof

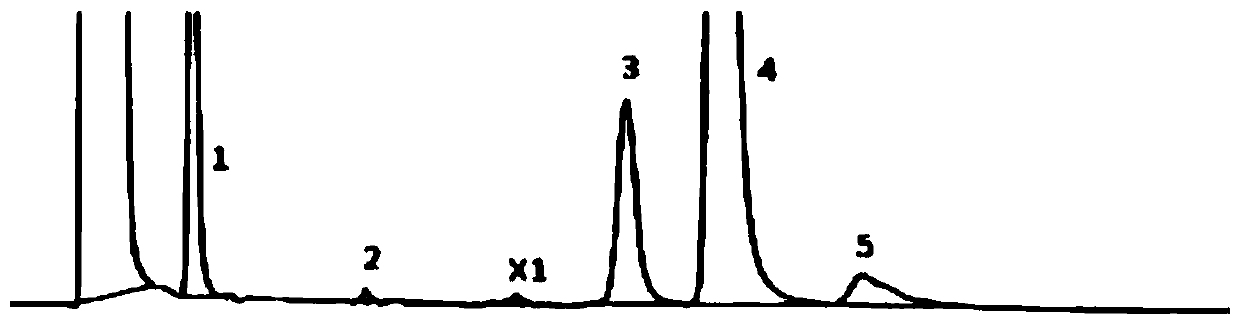

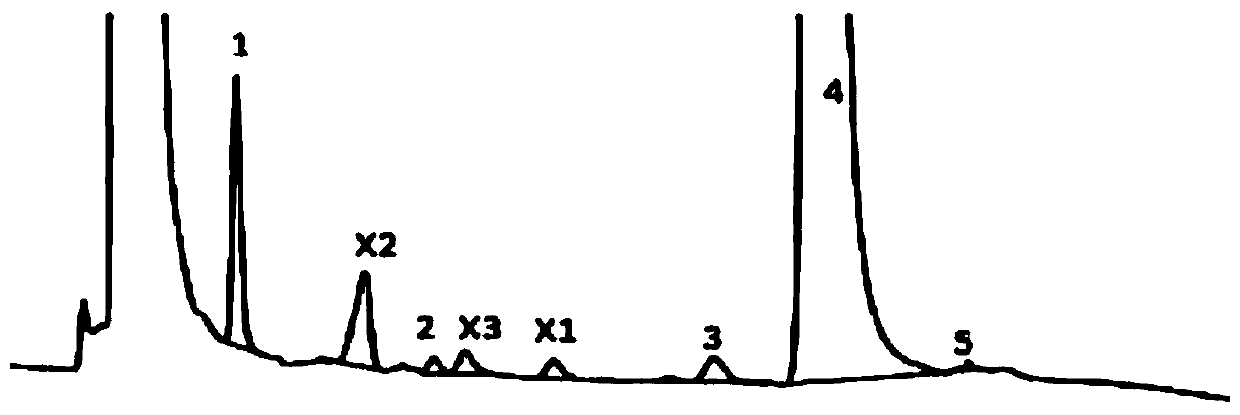

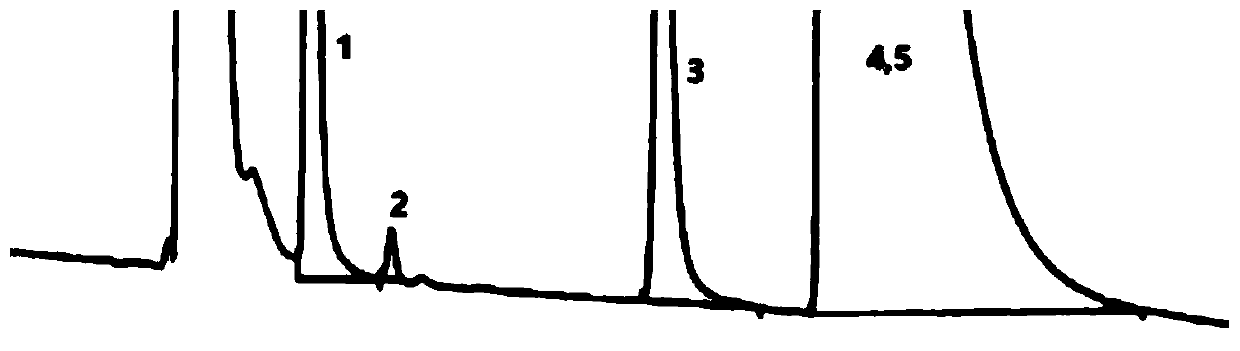

The invention discloses a high-performance liquid chromatography separation and determination method for impurities in a fosfomycin trometamol raw material drug and preparations thereof and an application thereof, aiming at separating the impurities. According to the method, the aminopropyl silane-bonded silica gel is used as a chromatographic column of a filler, a differential detector is used for detection; and a phosphate buffer solution and methanol-acetonitrile are mixed as a mobile phase; the method includes the following steps of: 1, preparation of a system suitability solution: wettinga raw material drug or a preparation with water, heating, and dissolving and diluting the raw material drug or the preparation by the mobile phase to obtain a solution A; dissolving and diluting theraw material drug or the preparation by using the solution A to obtain the system suitability solution; 2, preparation of a test solution: taking the raw material drug or the preparation, and adding the mobile phase for dissolving and dilution to obtain the set content of fosfomycin trometamol as the test solution; 3, preparation of a reference solution: diluting the test solution by using the mobile phase to obtain a solution containing fosfomycin trometamol equivalent to a mass concentration of 0.3-0.5% of the test solution as the reference solution; and 4, determination method: separately injecting the above three solutions into a liquid chromatograph, and calculating the content of each impurity in the raw material drug by using a principal component self-control method.

Owner:SHANXI C&Y PHARMACEUTICAL GROUP CO LTD

Peach tree planting method on hillside

ActiveCN105359913AHigh sweetnessPrevent quality degradationBio-organic fraction processingExcrement fertilisersGelatin spongeSweetness

The invention provides a peach tree planting method on a hillside. The method comprises the following steps of (1) preparing before planting, (2) planting, including planting peach tree seedlings in various cement framework groups on a hillside from the bottom to the top according to a height gradual increase order, and (3) applying fertilizer, wherein in the fertilizer applying step, one month after plantation, a plurality spherical gelatin sponge are placed around a root of each peach tree seedling; a sunward hillside with the gradient of 37 to 45 degrees is selected; peach tree seedlings are planted in various cement framework groups on a hillside from the bottom to the top according to the height gradual increase order; the peach tree seedlings are distributed in a step shape to ensure the peach tree seedlings to enjoy the sunshine to the largest extent; with thorough sunniness, peach sweetness can be enhanced; a problem of peach quality decrease due to uneven sunniness acquired by peach trees planted on a flat land and lack of sunniness to lower sides of the peach trees can be solved; and hillside stability can be improved when the peach trees are planted on the hillside.

Owner:哈威光电科技(苏州)有限公司

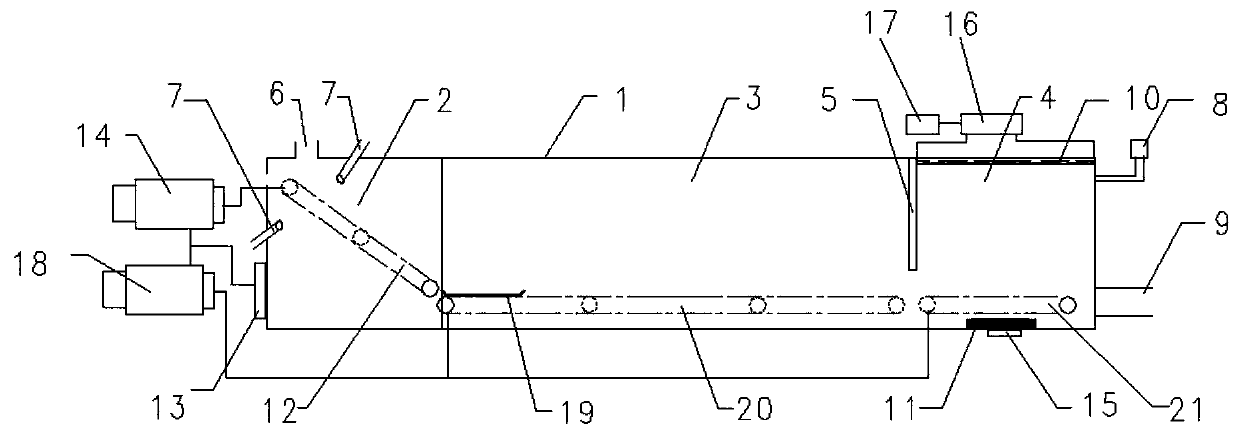

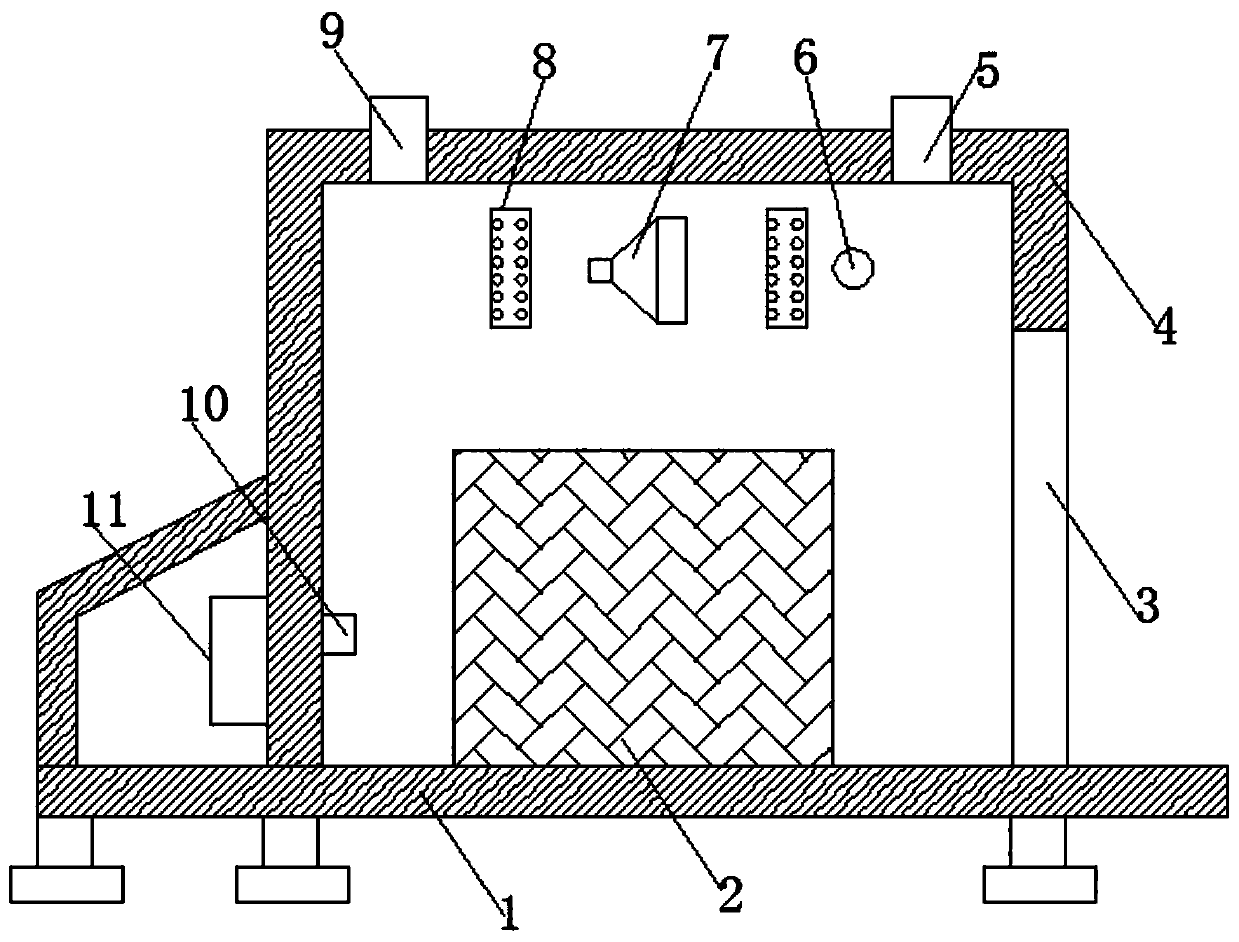

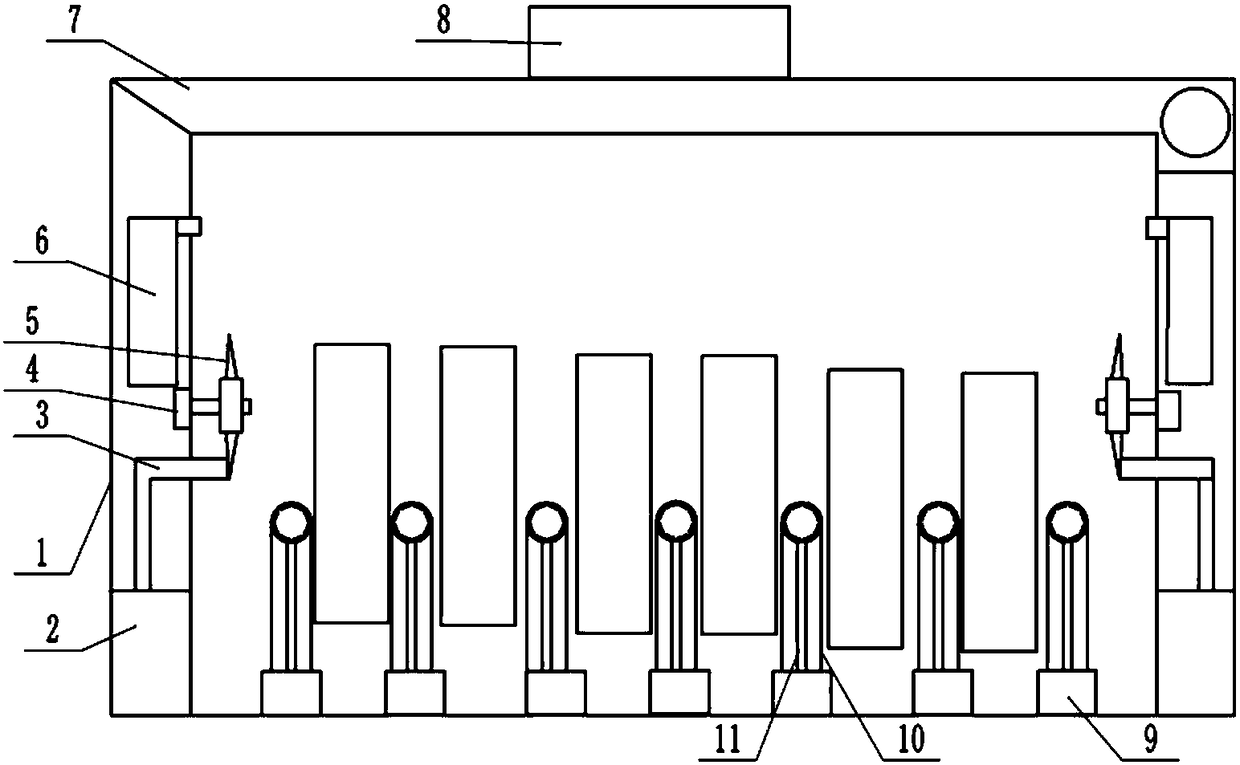

Making equipment of dried Gong pear slice and making method thereof

ActiveCN109527619AInhibits enzyme activityInhibits enzymatic browningFood treatmentElectricityMotor drive

The invention discloses making equipment of a dried Gong pear slice. The equipment includes a box body, the box body is equipped with an atomization chamber, a permeation chamber and a drying chamberfrom the head to the tail in order. The atomization chamber is communicated with the permeation chamber, the permeation chamber and the drying chamber are separated by a liftable baffle plate, and theatomization chamber is provided with a feed inlet and pipelines for introducing atomization liquid. The drying chamber is connected to a vacuum pump, and is equipped with an openable and closeable discharge port, and the inner wall of the drying chamber is provided with a cooling pipeline and a far-infrared electric heater. The three chambers in the box body are all equipped with conveying mesh belts. The outer side wall of the box body is equipped with a control plate and two motors driving the conveying mesh belts to move. The control plate is in electric connection with the two motors, anda switch in electrical connection with the far-infrared electric heater is disposed outside the box body. The equipment provided by the invention can perform physical and chemical color protection onthe Gong pear slice during preparation of the dried Gong pear slice, and the dried Gong pear slice has good color.

Owner:BAISE UNIV

Method for planting orange trees on mountain slope

ActiveCN105453976AHigh sweetnessPrevent quality degradationExcrement fertilisersAmmonium nitrate fertilisersOrange TreeSweetness

The invention provides a method for planting orange trees on a mountain slope. The method comprises the following steps of (1) preparation before plantation, (2) plantation, including planting orange tree seedlings in different cement frameworks along the mountain slope from the bottom to the top according to an order of orderly increased height, and (3) fertilizer application, including placing a plurality of spherical gelatine sponge surrounding a root of each orange tree. The mountain slope is sunward with gradient from 37 to 45 degrees; the orange tree seedlings with various heights are orderly planted in different cement frameworks from the bottom to the top along the mountain slope according to the order of increased height; the orange tree seedlings can be distributed in a step shape and sunlight is ensured for orange tree seedlings to the largest extent; with adquate sunniness, orange sweetness can be increased; a problem of low quality of oranges due to uneven sunlight when orange trees are planted on the flat land and leaves of the lower side of the orange trees cannot be illuminated; and mountain slope stability can be enhanced with the orange trees planted on the mountain slope.

Owner:重庆橙杨生态农业有限公司

Method for planting rice in saline-alkali land of Yellow River irrigation district

InactiveCN106386295AImprove salinizationLower pHBioloigcal waste fertilisersAmmonium salt fertilisersSteepingNutrient

The invention discloses a method for planting rice in a saline-alkali land of the Yellow River irrigation district. The method comprises the steps that (S1) seedling culture is carried out; (S2) calcium sulfate powder is scattered in a ploughed and stirred saline-alkali paddy field with loose and soft soil, ploughing and stirring are conducted again, the paddy field is leveled, water is injected till the water level is 5-10 cm higher than the flat soil surface, and field steeping is continued for 7-10 days; (S3) water accumulated on the field surface is discharged, washing with flowing water is conducted for one time, a soil conditioner is applied, ploughing and leveling are conducted again, water is injected till the water level is 3-7 cm higher than the water surface, and rice seedlings are inserted; and (S4) additional fertilizers are applied periodically to supplement rice nutrients till the rice gets mature. The method for planting the rice in the saline-alkali land of the Yellow River irrigation district disclosed by the invention has the advantages that operations are simple; the programming degree is high; promotion is easy; the planting cost is low; soil salinization can be improved; a soil pH value can be reduced; soil fertility can be increased; and the yield of the rice planted in the saline-alkali land can be increased by 20%-30%.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

Configuration method for light-potentially rocky desertification environmental plant hedge in karst region

ActiveCN106612698AReduce churnIncrease coverageAgriculture gas emission reductionSoil-working methodsLand consolidationTrifolium repens

The invention discloses a configuration method for light-potentially rocky desertification environmental plant hedge in karst region. The configuration method comprises selection of plant hedge planting type, land consolidation, plant hedge planting, late stage watering management, later stage pruning management forming plant hedge configuration form of pyracantha fortuneana, climbers+shrubs+herbs, climbers+small trees+herbs, herbs+shrubs; the plant hedge configuration form of pyracantha fortuneana, climbers+shrubs+herbs, climbers+small trees+herbs, herbs+shrubs is obtained in the method, control of soil erosion is conducted concerning light-potentially rocky desertification in karst region, the surface coverage is increased, the surface flow rate is reduced, the soil erosion is decreased, and the soil fertility is improved and preserved. Cash crops such as Hypericum monogynum, pyracantha fortuneana, Trifolium repens, and Prunus Humilis Bunge are planted. Crop yield is high, terrace stability and economic incomes of peasants are improved, the usage rate of the soil in karst region is increased, and the method is especially accepted by peasants in light-potentially rocky desertification environment.

Owner:GUIZHOU NORMAL UNIVERSITY

Wood drying kiln

InactiveCN110173964AProof qualityGuaranteed qualityDrying gas arrangementsDrying machines with non-progressive movementsInstabilityNational standard

Owner:安徽繁盛木业包装有限公司

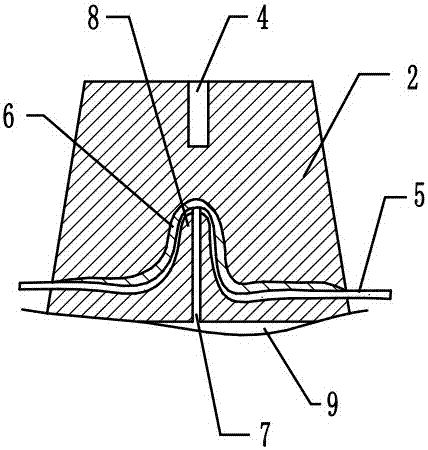

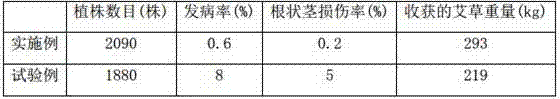

Planting method for wormwood

InactiveCN107087488AReduce pests and diseasesAvoid damageWatering devicesPlant cultivationSite managementSoil preparation

The invention relates to the technical field of plant planting and cultivating, in particular to a planting method for wormwood. The planting method comprises the following steps of film mulching and soil preparation, ploughing and seedling planting, field management, seedling harvest and plant dividing; thin film is placed at the bottoms of field ridges during film mulching and soil preparation, during plant dividing and seed overturning, the thin film is shaken to loosen soil on the upper portions of the field ridges, and then wormwood roots are selected out directly. According to the planting method of the wormwood, the thin film can reduce the loss of water on the upper portions of the field ridges, pests and diseases of the wormwood roots are reduced, and the damage to the wormwood roots in plant dividing and seed overturning can be prevented.

Owner:贵州务川八爷农场有限公司

Production process for preparing novel carburant from carbon solid waste material

ActiveCN111302753AWeakened water retentionEasy to hardenSolid waste managementProcess engineeringEnvironmental engineering

The invention discloses a production process for preparing a novel carburant from a carbon solid waste material. A binder which is low in cost, high in viscosity, non-toxic, odorless, green and environment-friendly is selected to replace coal pitch. Carbon solid waste is subjected to a series of procedures of crushing, screening, purifying, stirring, mixing, kneading, profiling, drying, cooling and packaging, and through the step of water locking, the carbon solid waste is convenient to form, good in toughness and high in strength.

Owner:江苏嘉明碳素新材料有限公司

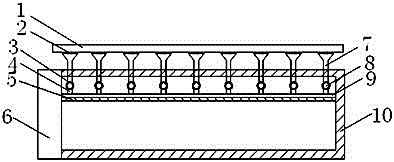

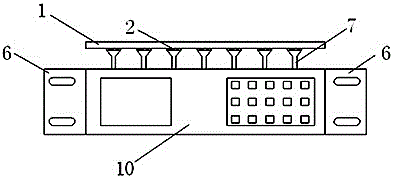

Door control server

InactiveCN106598182AChurn fastImprove cooling efficiencyDigital data processing detailsIndividual entry/exit registersEngineeringCopper

The invention discloses a door control server. The door control server comprises a shell; mounting plates are arranged on two sides of the shell; a heat conduction plate is arranged in the shell; the periphery of the heat conduction plate is connected with the inner walls of the shell; a heat absorption layer is arranged at the bottom of the heat conduction plate; a plurality of copper pipes are arranged above the heat conduction plate; two ends of each copper pipe are connected with the inner walls of the shell; a plurality of heat conduction rods are arranged at the bottoms of the copper pipes; the bottoms of the heat conduction rods are connected with the heat conduction plate; the copper pipes are filled with volatile liquid; a plurality of transmission pipes are arranged at the tops of the copper pipes; the top of each transmission pipe extends to the position above the shell; a condensation plate is arranged at the top of each transmission pipe; and a heat dissipation plate is arranged above the shell. The door control server is simple in structure, relatively low in cost, economic and practical, and can have relatively good heat dissipation performance; and elements in the door control server can be protected.

Owner:NANLING ZHILIAN ELECTRONICS TECH

Preparation method of inflation pool with permanent antibacterial function

InactiveCN106515055AAntibacterial agent natural long-lasting antibacterialPlay a supporting roleHollow wall articlesHollow articlesAntibacterial effectHeavy metals

The invention provides a preparation method of an inflation pool with a permanent antibacterial function. A process of bonding a double-layer PVC material on warp-knitted and weft-inserted cloth is adopted; the inner layer of PVC material mainly achieves the waterproof effect; the outer layer of PVC material mainly achieves the antibacterial effect; the warp-knitted and weft-inserted cloth achieves the support effect; marbles are added; a natural replacement mode is used for using all antibacterial agent in the whole outer layer of PVC material to not only achieve the surface antibacterial effect; expanded vermiculite powder is added to achieve the following main effects: (1) a certain absorbing effect is achieved on a nanosilver antibacterial agent to prevent quicker loss of nanosilver under acid conditions; and (2) a certain absorbing and treating effect is achieved on other impurities in water, in particular heavy metals. The preparation method of the inflation pool with the permanent antibacterial function achieves natural and permanent antibacterial effect of the antibacterial agent through adding nanosilver, marble leftovers and expanded vermiculite powder in traditional PVC films.

Owner:长兴勇强塑胶有限公司

Working method of pork refrigeration equipment

ActiveCN108592470AEasy to openEasy to closeLighting and heating apparatusDomestic refrigeratorsImpellerAir pump

The invention belongs to the field of refrigeration devices and specifically relates to a working method of pork refrigeration equipment. The equipment comprises a cabinet; a top of the cabinet is hinged with a cover plate for sealing; multiple air pumps are installed at the bottom of the cabinet with intervals; the air pump is provided with a rubber pipe; the rubber pipe is provided with an air pipe therein; the air pipe is connected with an output end of the air pump; a top of the rubber pipe is provided with a ball; the circumferential surface of the ball is provided with a plurality of through grooves; the inside of the ball is provided with an expansion sleeve; a surface of the expansion sleeve is provided with a plurality of spurs in the through grooves, and the expansion sleeve is connected with the air pump; a refrigerator for cooling is provided at the upper portion of the side wall of the cabinet; a water tank is arranged in the side wall of the cabinet; a side wall of the cabinet is provided with a horizontal tube leading to the inside of the cabinet; the horizontal pipe is connected with the water tank, and an impeller driven by the motor is arranged between the horizontal pipe and the refrigerator; the edge of the impeller abuts the outlet of the horizontal tube. This program can avoid pork adhesion, prevent pork damage and keep pork moisture.

Owner:重庆三欣冷冻食品有限公司

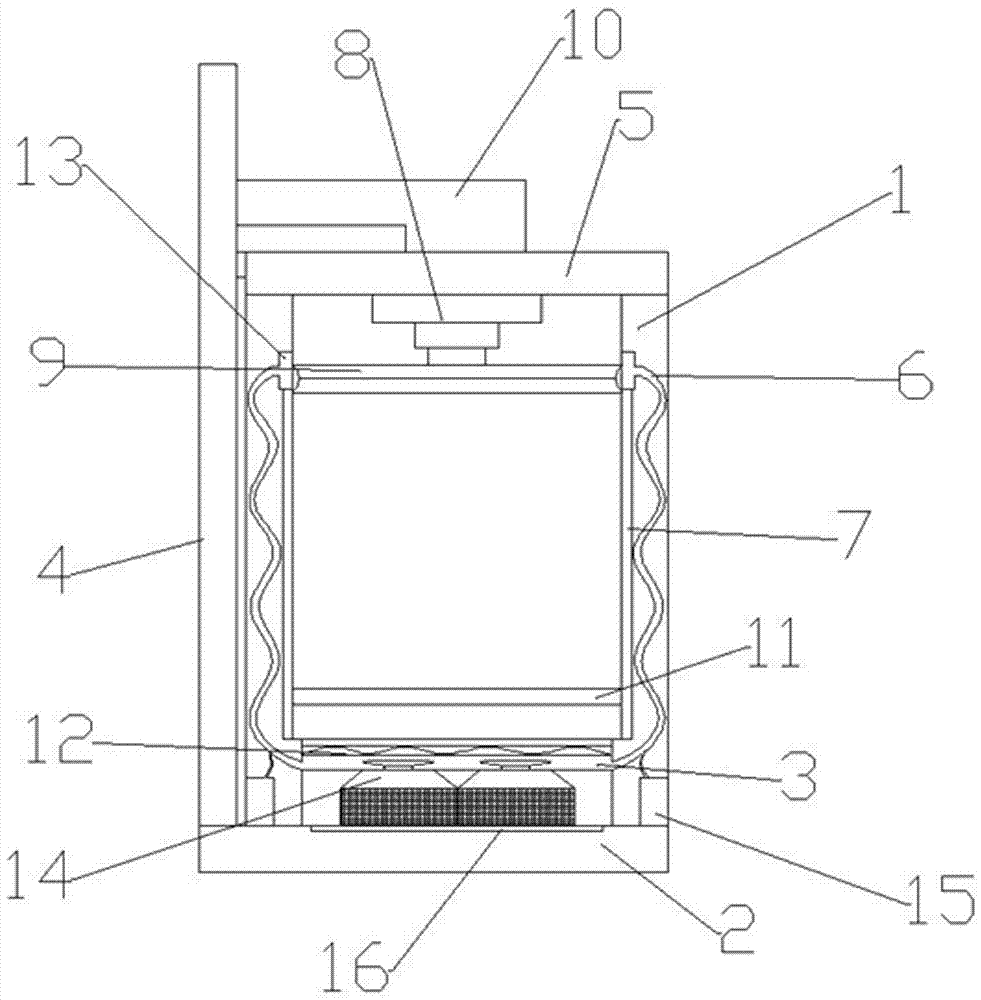

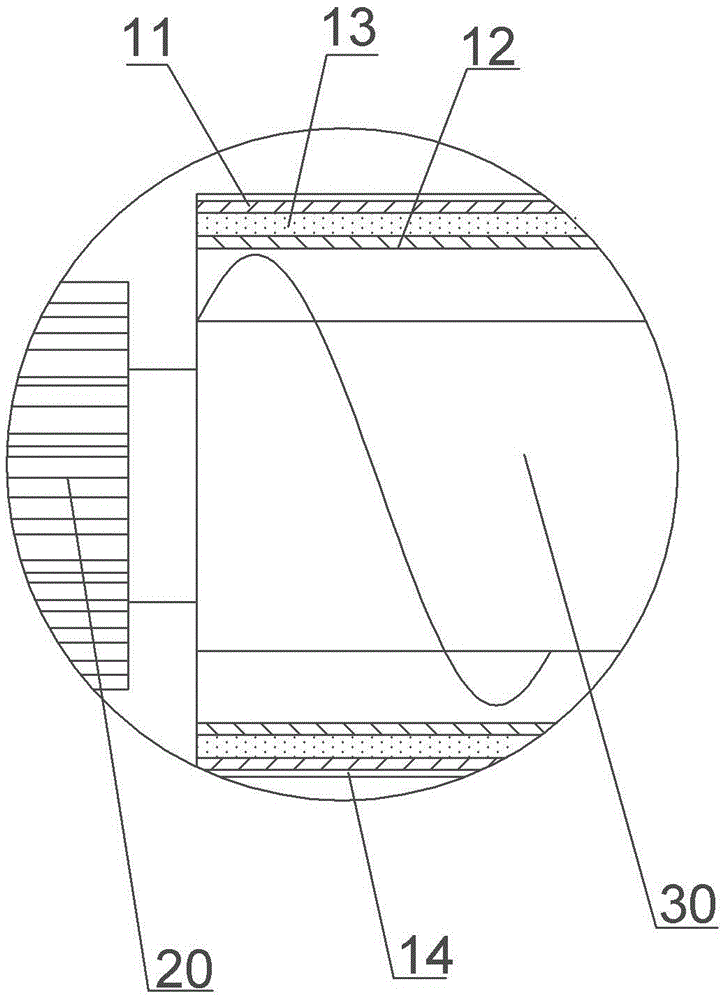

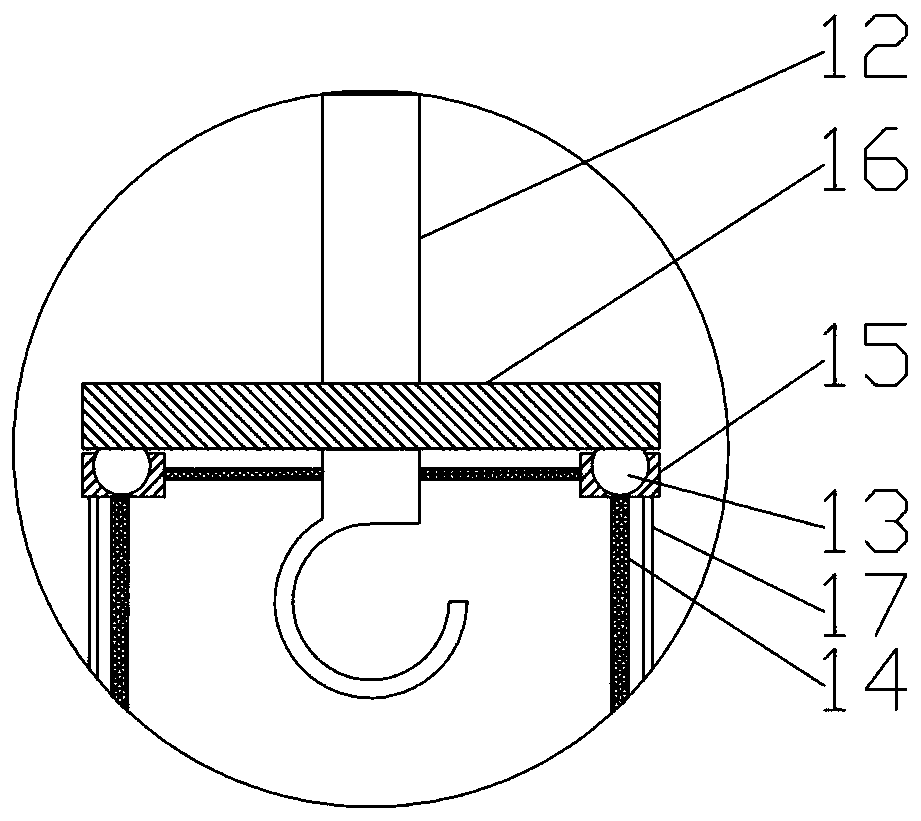

Rapid clothes dryer

InactiveCN108004741AIncrease contact areaImprove drying efficiencyTextiles and paperLaundry driersAgricultural engineeringEnergy conservation

The invention discloses a rapid clothes dryer, and belongs to the technical field of drying equipment. The upper end of the rapid clothes dryer is a rack cover 5, the rack cover 5 is connected with alifting rack 4 through a connecting device, the lower end of the rack cover 5 is connected with an air pressure device 8, the lower end of the air pressure device 8 is connected with a piston 9, a rack is arranged at the lower end of the rack cover 5, an air collecting opening 13 is formed in the upper end of the rack 1, a condenser pipe 6 is arranged in an interlayer of the rack 1, a water collecting tank 15 is arranged at the lower end of the condenser pipe 6, an insulating plate 7 is arranged on the inner side of the rack 1, a stopping plate 11 is arranged on the bottom of the rack 1, a drying device 3 is arranged at the lower end of the stopping plate 11, the drying device 3 is provided with a heating resistance wire 12, a drying fan 14 is arranged at the lower end of the heating resistance wire 12, and is placed on a rotary wheel plate 15, and the whole device is placed on the base 2. The rapid clothes dryer is high in clothes drying efficiency; the time is short; and the energy is saved.

Owner:吴迪

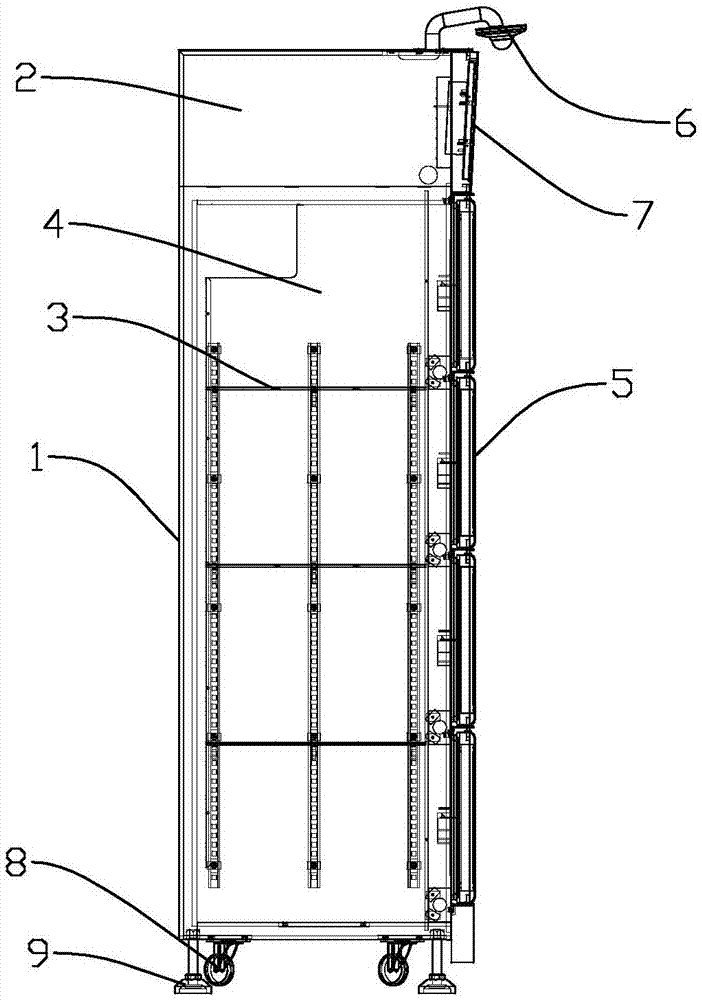

Novel intelligent vending machine

The invention discloses a novel intelligent vending machine. The novel intelligent vending machine comprises a shell, a refrigeration system and a control system; the shell is divided into a pluralityof cavities through clapboards, each cavity is opened and closed through an independent door body, the refrigeration system is arranged above the shell and used for refrigerating the interior of theshell, through holes are formed in the clapboards, and the control system controls the operation of the refrigeration system and opening and closing of the door bodies. According to the novel intelligent vending machine of the structure above, by dividing the interior of the shell into the cavities and controlling opening and closing of the cavities through the independent door bodies, any one cavity which needs to be opened can be opened just by opening the corresponding door body, and too quick energy loss caused by opening of all the cavities is avoided; in addition, the refrigeration device is independently arranged above the shell, pipelines can be centralizedly distributed, and the pipeline layout can be simplified just making an output end of the refrigeration device communicated with the cavities.

Owner:广东思迈尔智能科技有限公司

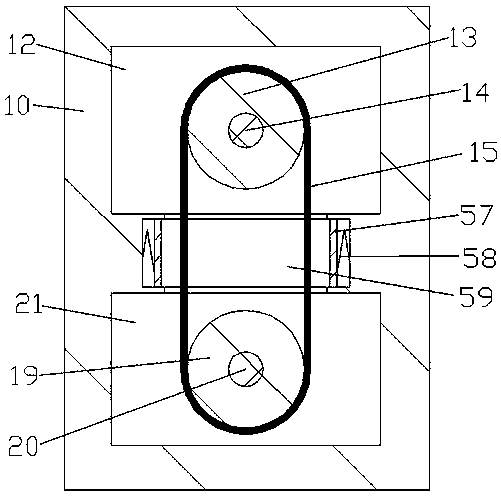

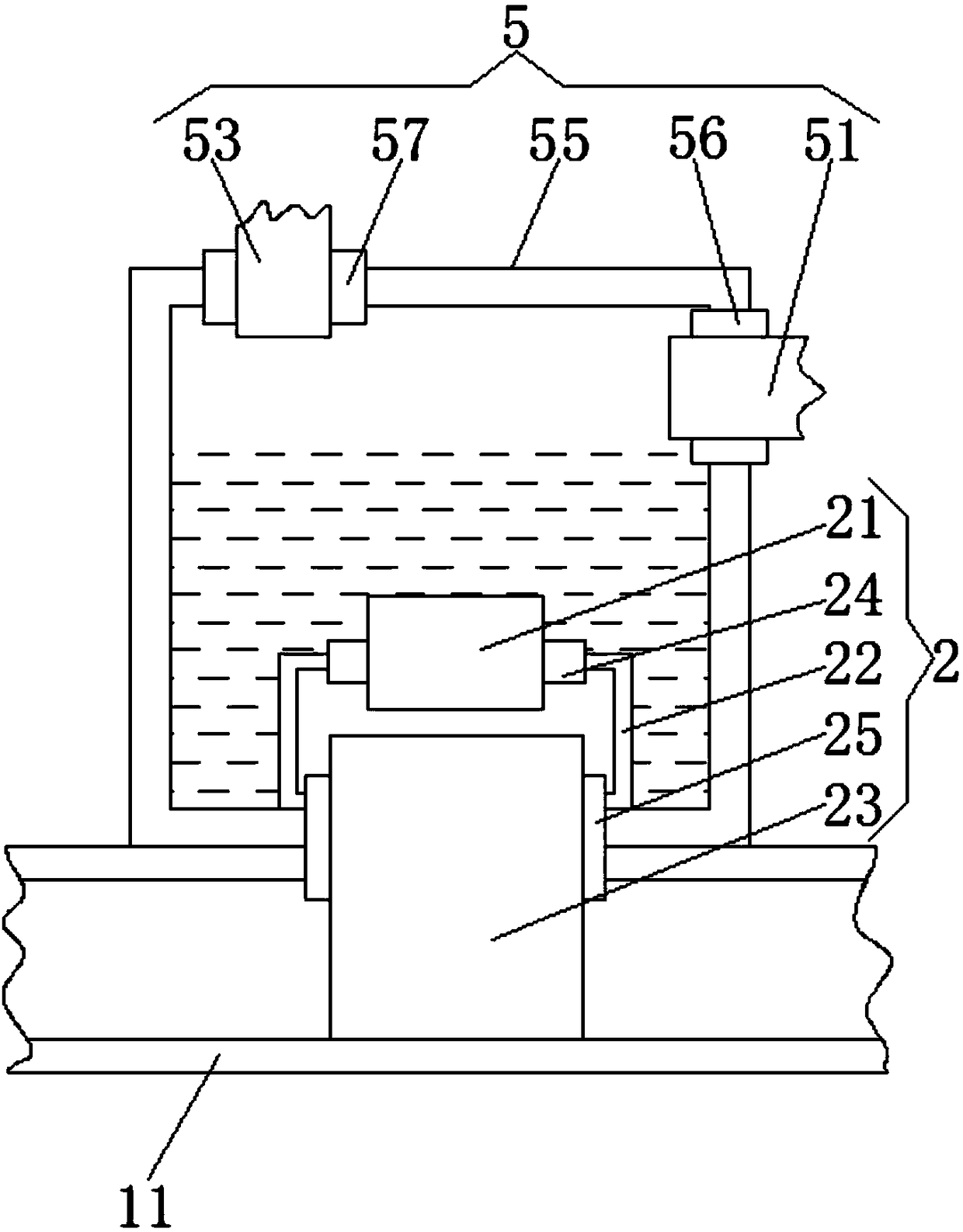

Continuous sugar cooking device

InactiveCN105533087AEvenly heatedAvoid insufficient caramelizationConfectionerySweetmeatsElectricityThermal energy

The invention belongs to the field of sugar cooking equipment, and specifically discloses a continuous sugar cooking device. The continuous sugar cooking device comprises a sugar cooking pipe, a motor, a stirring shaft, and a controller. The sugar cooking pipe is provided with a material inlet. The material inlet end of the sugar cooking pipe is provided with the motor, which is rotatingly connected to a motor output shaft; the output terminal of the motor is connected to one end of the stirring shaft, the stirring shaft is provided with a blade, the sugar cooking pipe is provided with a jacket layer, water with a temperature higher than 75 DEG C is filled in the jacket layer, a magnetic member is arranged in the internal wall of the sugar cooking pipe, a temperature sensor is arranged in the sugar cooking pipe, the motor and the temperature sensor are both electrically connected to the controller, and the discharge end of the sugar cooking pipe is provided with a blower fan which can accelerate the flowing out of air. The rotation of stirring shaft can generate thermal energy, which is used to heat sugar, at the same time, the heating temperature is controlled through the temperature sensor and the controller, the quality of sugar cooking is improved, and the time is saved.

Owner:CHONGQING TANHULU FOOD CO LTD

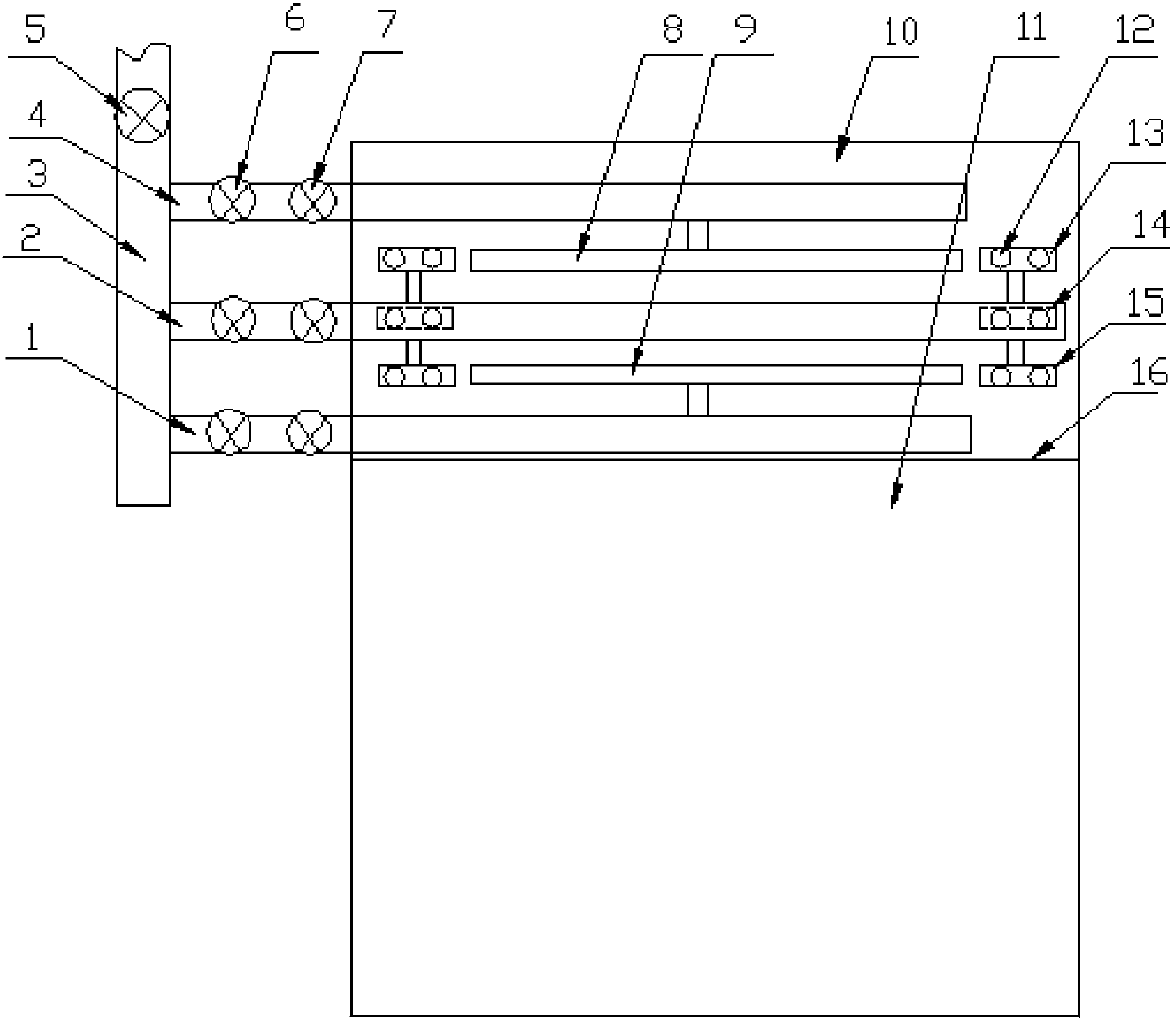

Sintering ignition furnace and ignition control process thereof

PendingCN107830736AEnhanced side fire strengthEnsure ignition strengthFurnace typesGaseous fuel burnerZone meltingGas burner

The invention provides a sintering ignition furnace and an ignition control process thereof and belongs to the field of sintering ignition devices. The sintering ignition furnace comprises an ignitionchamber, and one or more rows of side edge nozzle gas pipes are additionally arranged in the ignition chamber. A plurality of rows of side edge nozzles are arranged at the two ends of each side edgenozzle gas pipe correspondingly, and each row of side edge nozzles comprises the one or more side edge nozzles which all communicate with the corresponding side edge nozzle gas pipes. According to thesintering ignition furnace and the ignition control process thereof, aiming at the problems that in the prior art, as for an ignition furnace, the middle of a material surface is prone to being super-fused, and the ignition effect on the two sides is poor, the sintering edge ignition intensity can be guaranteed, and a middle area can also be not super-fused under ignition.

Owner:MAANSHAN IRON AND STEEL COMPANY

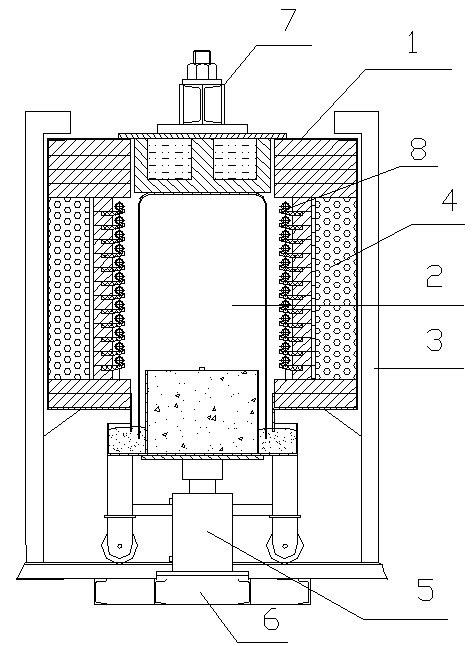

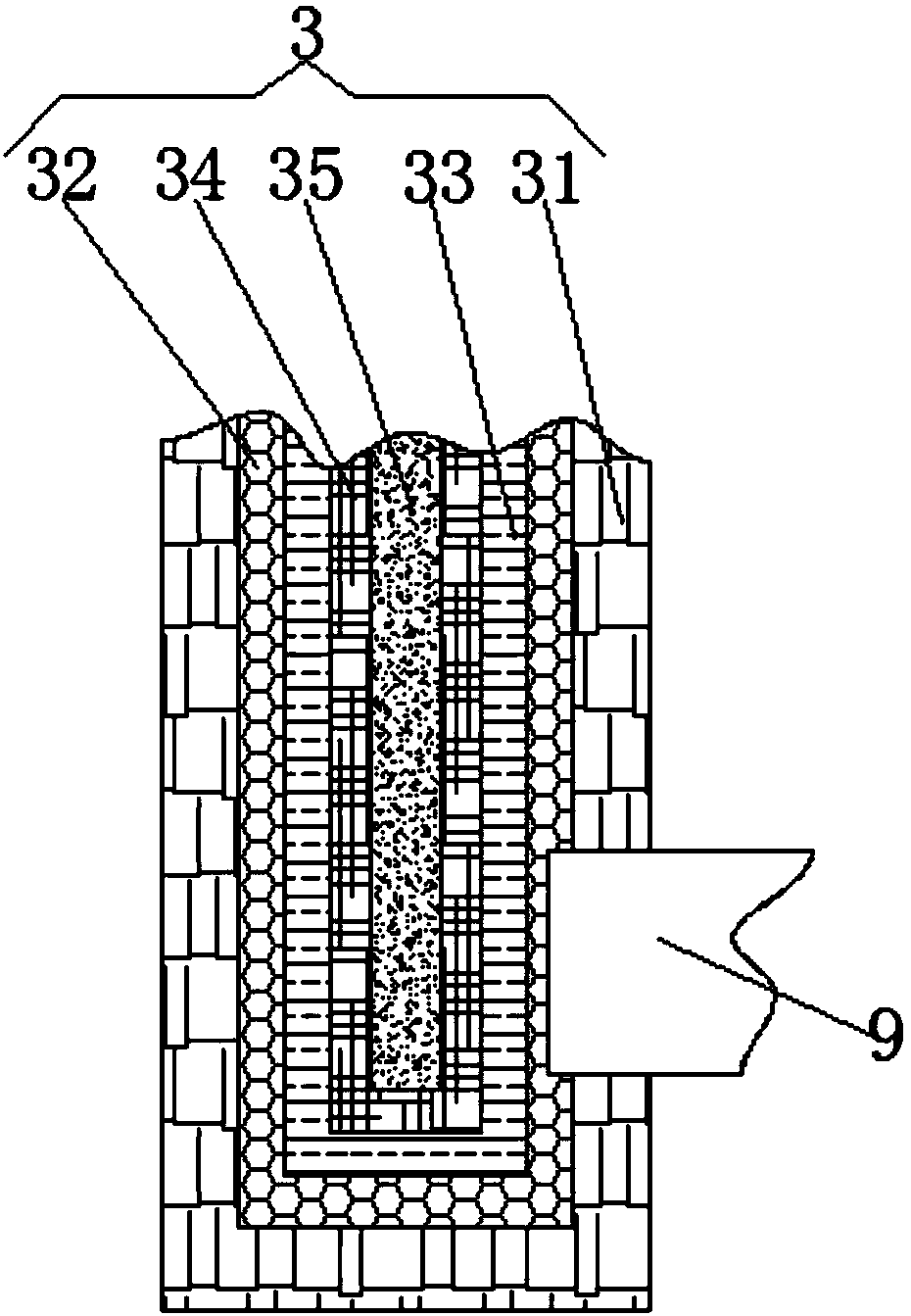

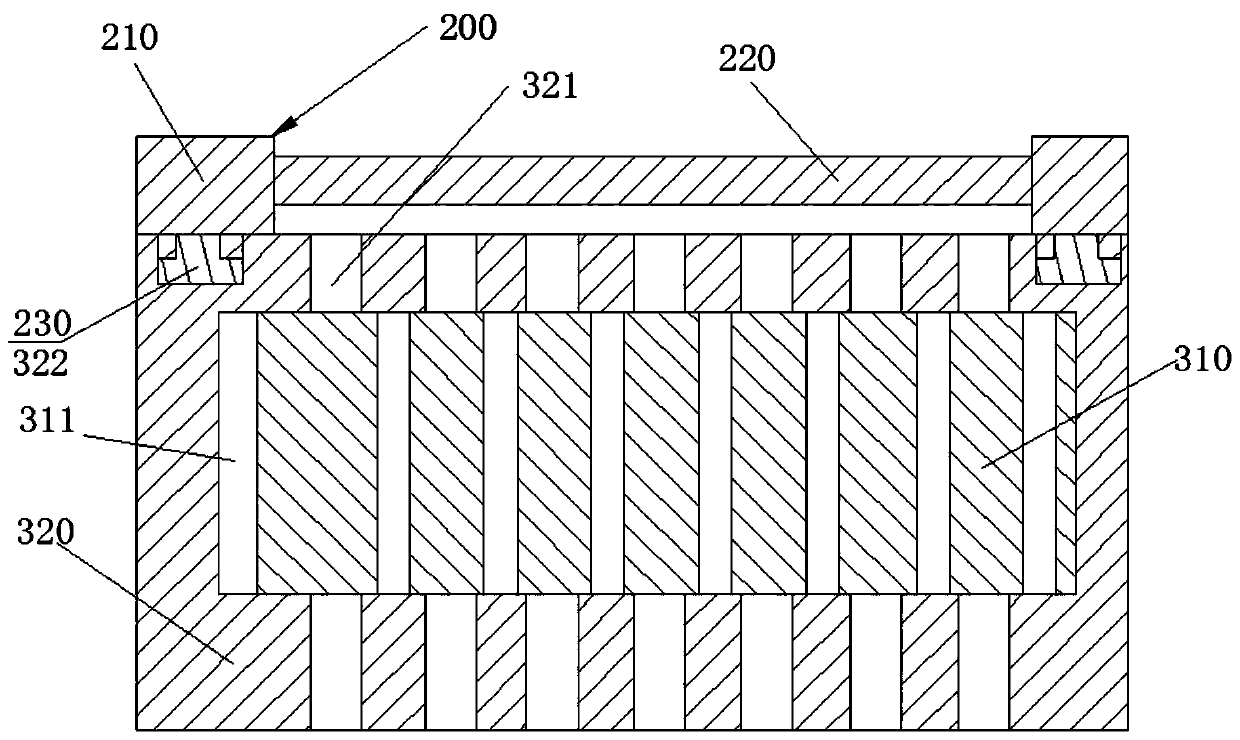

Two-post pressurizing furnace

InactiveCN103453775APrevent falling offExtend your lifeElectric heating for furnacesMonolithic liningsBrickMetallurgy

The invention provides a two-post pressurizing furnace. The pressurizing furnace comprises a furnace body, a furnace pipe, a furnace lining, a guide post, a top cylinder and a base, wherein the furnace lining comprises brick layers and fireproof fibre layers, the brick layers are located on one side adjacent to the furnace pipe, certain spaces between the brick layers in the furnace lining are used for fixing heating elements, so as to effectively prevent the heating elements from falling off in the working process; the fixing effect is better, so that the life of the heating elements can be prolonged. The two-post pressurizing furnace has the beneficial effects that the furnace lining is made from the brick layers and the fireproof layers, therefore, on the one hand, the service life of the heating elements can be effectively prolonged by the structure of the brick layers; on the other hand, the fireproof fibre layer can guarantee that the heat quantity in the whole inner furnace does not run off too fast, so as to play a role in saving energy to a certain degree.

Owner:JIANGSU GAOHAO IND FURNACE

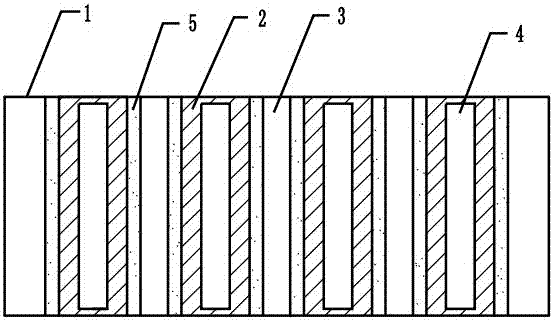

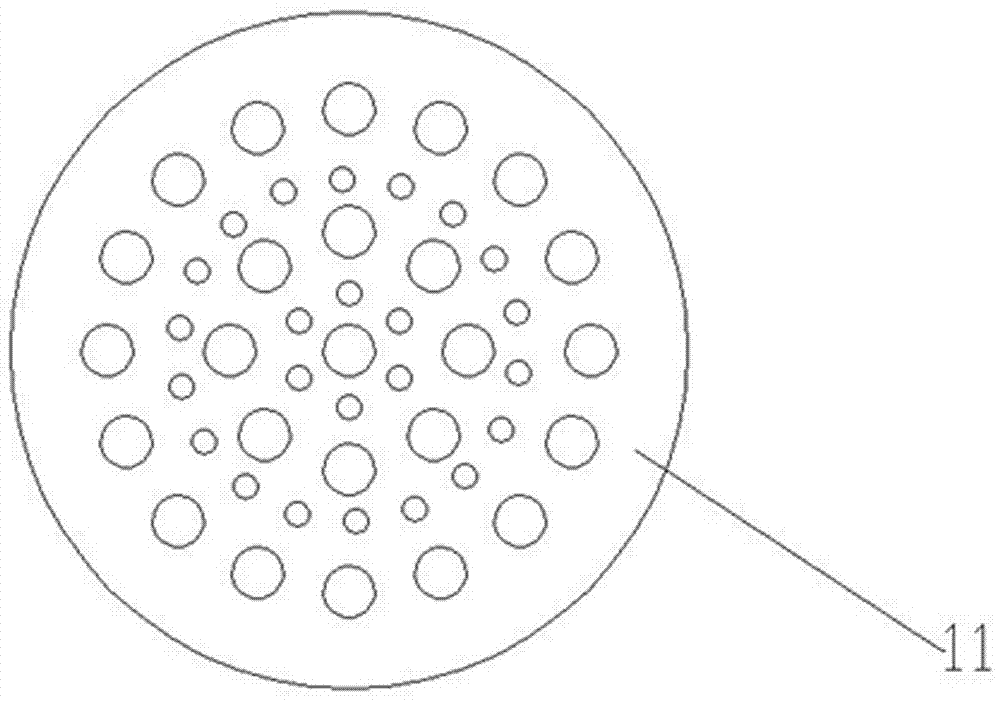

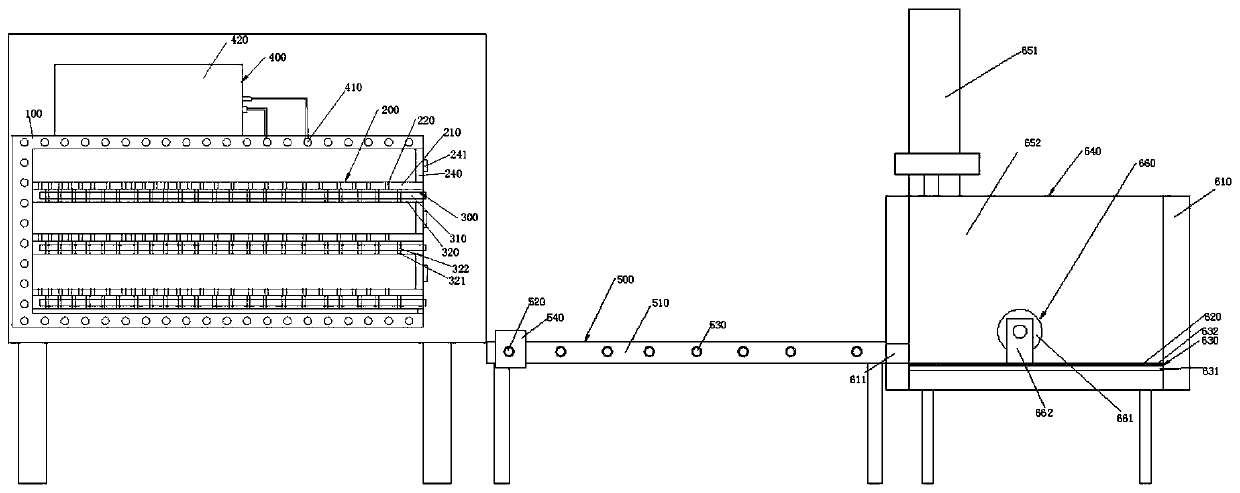

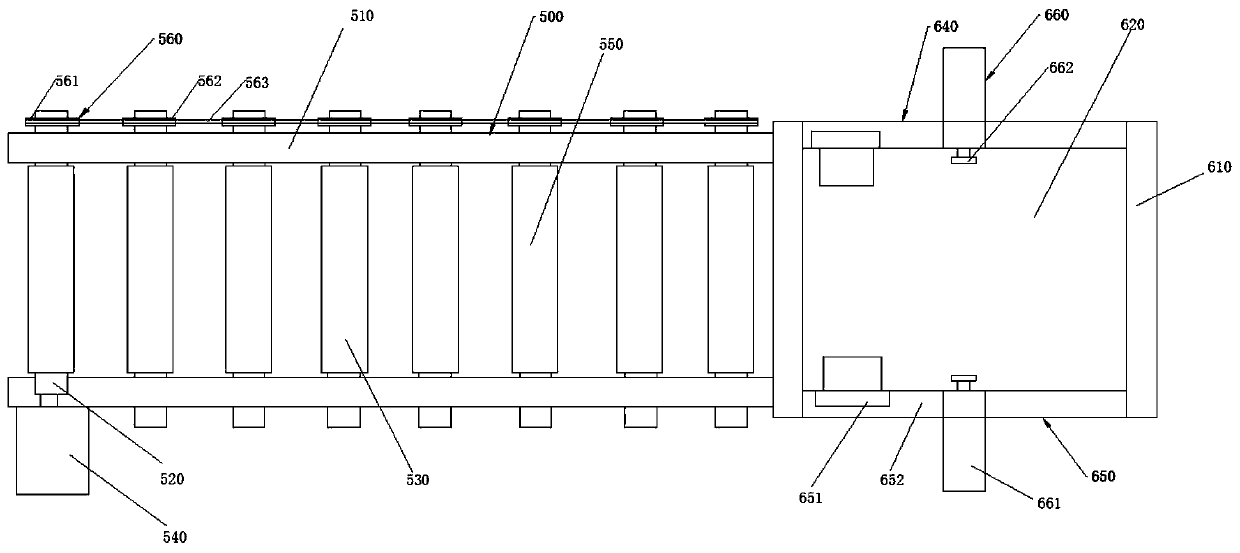

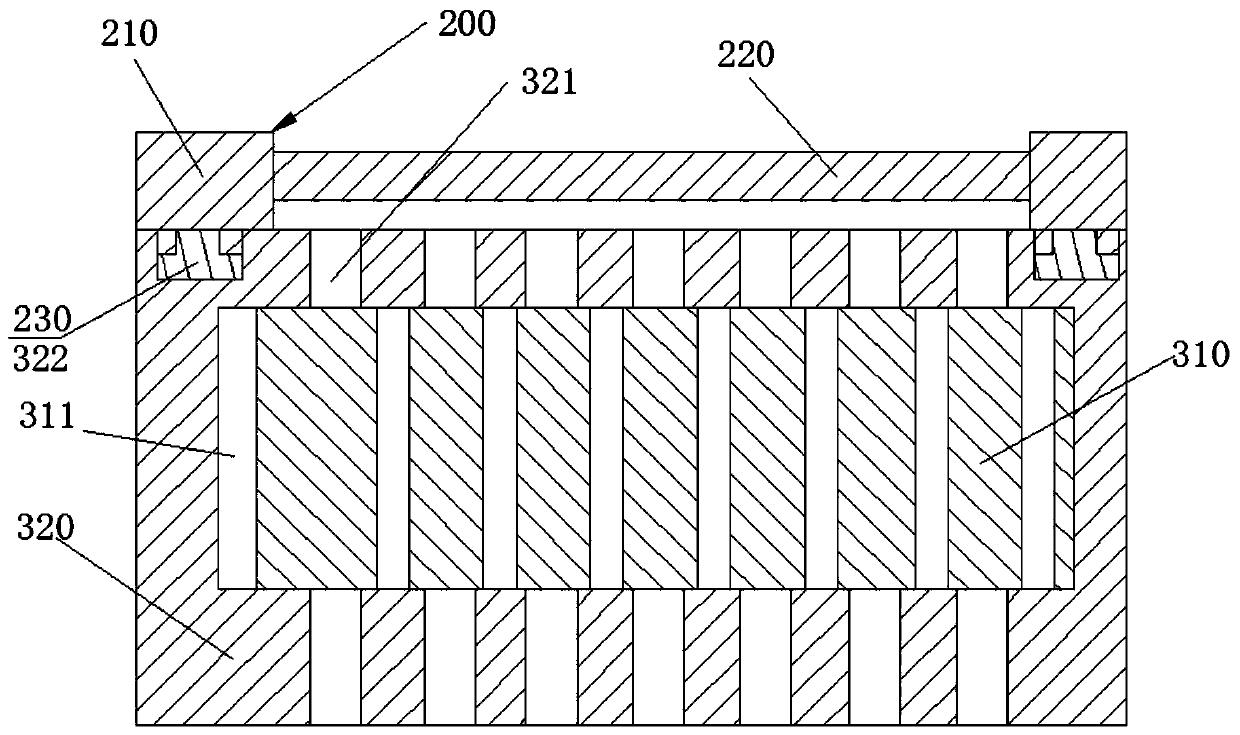

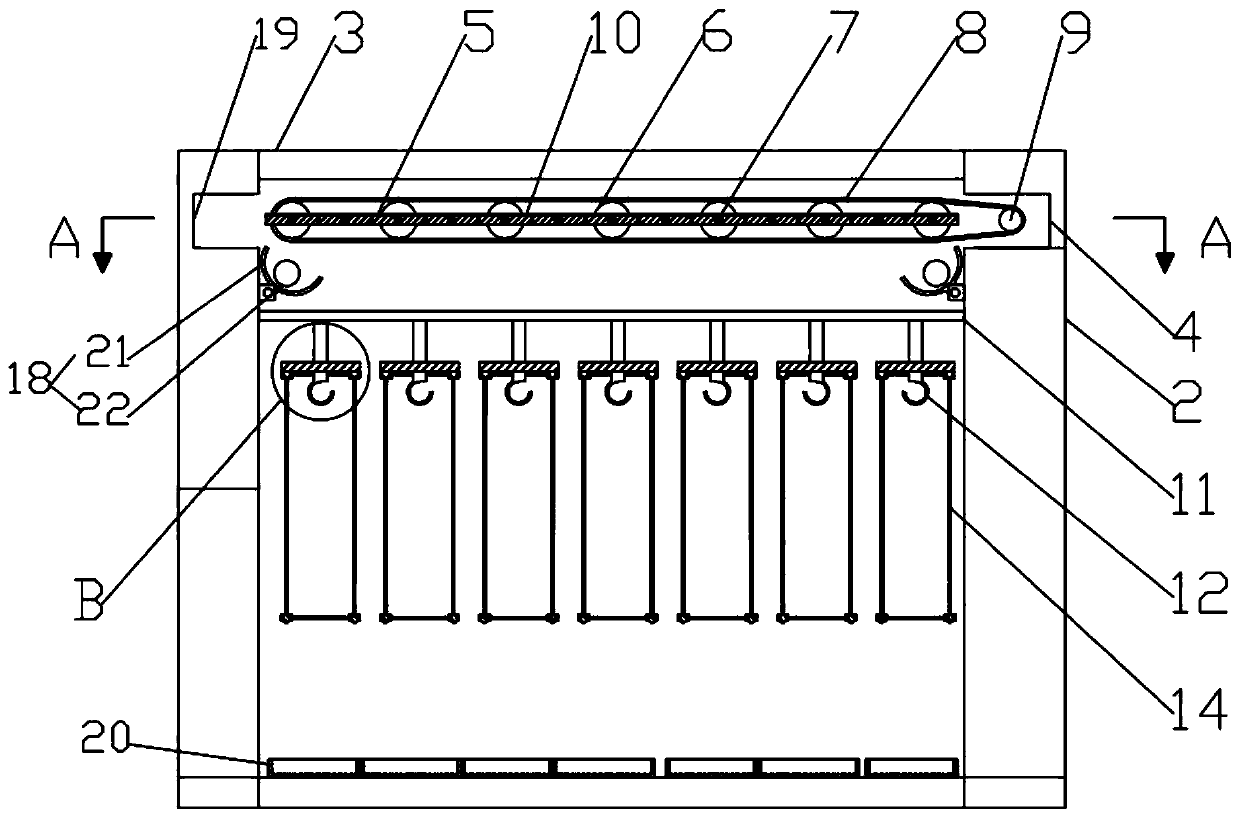

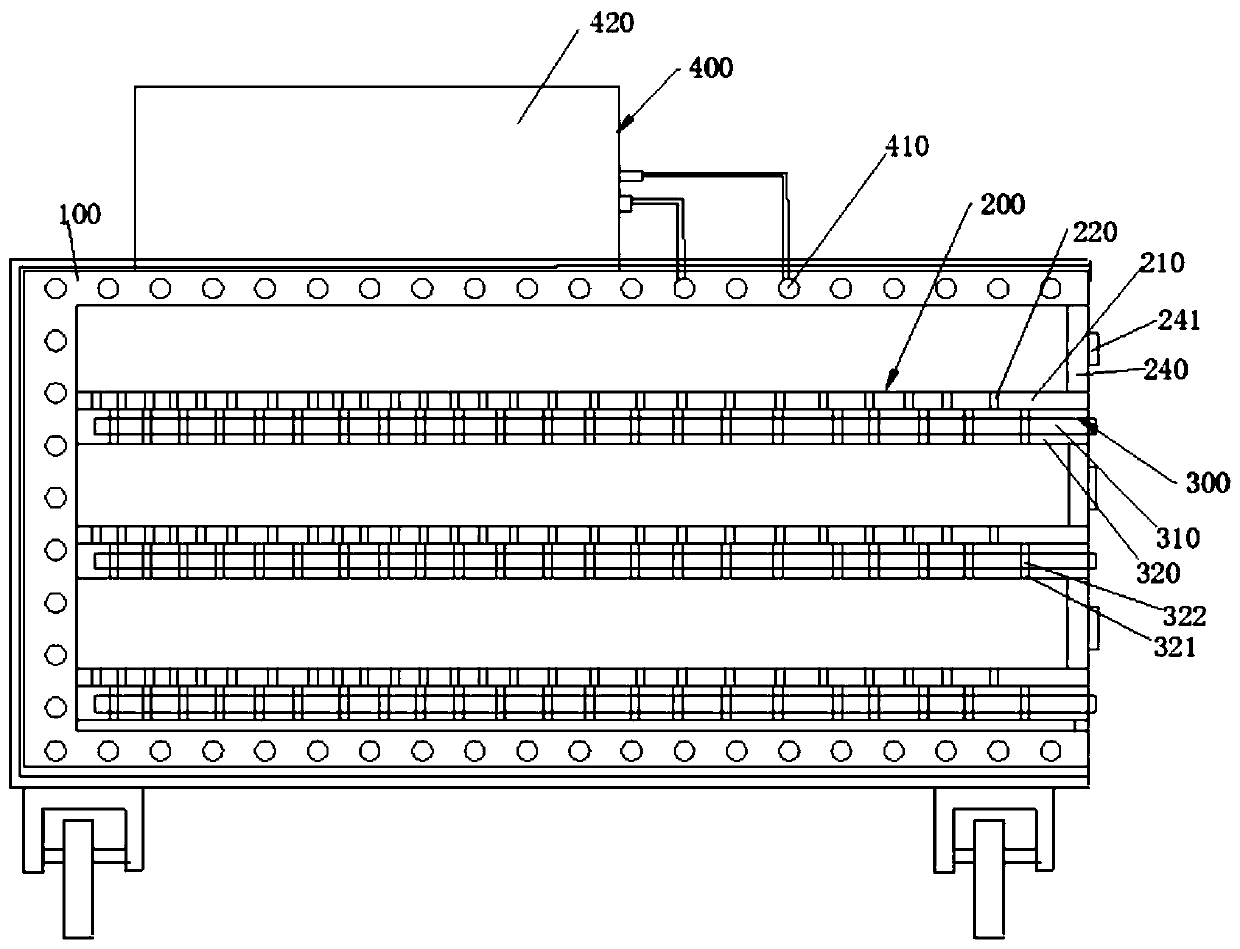

Production line for processing ground bricks

ActiveCN109940749AImprove uniformity and efficiencyAvoid losing heat too quicklyDischarging arrangementCeramic shaping plantsHeating systemEngineering

The invention provides a production line for processing ground bricks. The production line comprises a box body, drying supports, separating plates and a heating system, wherein the plurality of separating plates are arranged in the height direction of the box body, the separating plates are arranged in the same direction of the box body, each separating plate comprises an inner plate and an outerplate, a containing cavity is formed in the outer plates, the outer plates are arranged in a containing cavity, a plurality of through holes I are formed in the outer plates in a penetrating mode, and a plurality of through holes II are formed in the inner plates; the inner plates and the outer plates are in transverse sliding connection, so that the through holes I can communicate and can be staggered as well, the drying supports are all arranged on each outer plate, the drying supports are in sliding connection with the outer plates, and sealing door sheets are arranged at the front ends ofthe drying supports correspondingly; and the heating system comprises oil pipes and a heat conduction oil furnace, wherein the heat conduction oil furnace is arranged on the box body, and the oil pipes are distributed in the side wall of the box body, an oil inlet and an oil outlet of the heat conduction oil furnace communicate with the oil pipes correspondingly.

Owner:丽水市知源科技有限公司

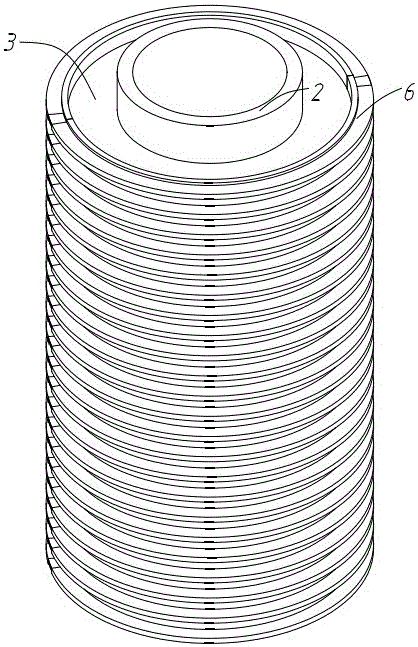

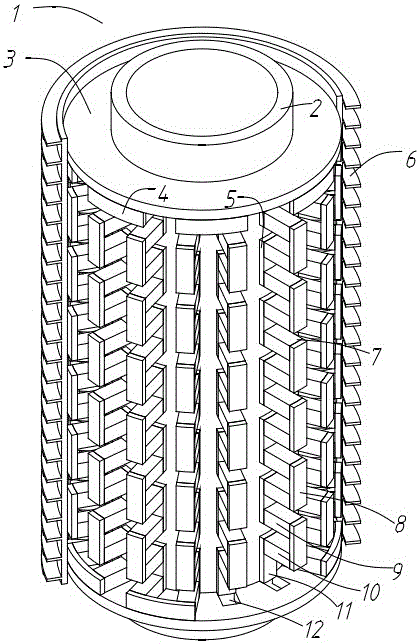

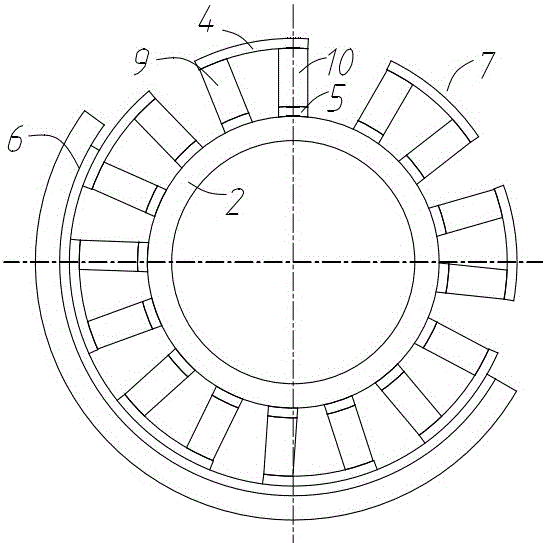

Cylindrical heat source thermoelectric generation device

InactiveCN106602932ASolve the problem of not being able to fit effectivelyReduce conductionGenerators/motorsOne-hotEnergy recovery

The invention discloses a cylindrical heat source thermoelectric generation device in the field of energy recovery technology. The device comprises a plurality of P-type semiconductors, a plurality of N-type semiconductors, a plurality of hot-end conductive plates and a plurality of cold-end conductive plates. One P-type semiconductor, one hot-end conductive plate, an N-type semiconductor and a cold-end conductive plate are serially connected in an end-to-end manner, thereby forming a PN junction. All PN junctions are connected in an end-to-end manner, thereby forming a semiconductor chain. The semiconductor chain is arranged in a repeated manner along the axial direction of the external wall of the cylindrical heat source. All hot-end conductive plates are fixedly connected with the external wall of the heat source. All cold-end conductive plates are connected with the inner surface of a heat radiator. The external wall of the heat source is directly used as the heat-end substrate of a thermoelectric generation module. When the heat source operates and radiates heat to outside, because the heat end of the thermoelectric generation module is the outer wall and no superfluous heat conduction process exists, relatively high hot-end temperature and relatively high temperature increase speed are obtained, thereby improving heat conduction efficiency and realizing higher thermoelectric generation efficiency.

Owner:JIANGSU UNIV

Ventilating cabinet

The ventilating cabinet with arm port on the door consists of a casing, a console, a blower, an exhaust pipe and a door. On the door, there are arm ports with glove and self sealing device. Inside the ventilating cabinet, there may be air intake pipeline and air regulating valve as required. The present invention is used mainly for chemical, physical, biochemical and other experiments.

Owner:刘继洲

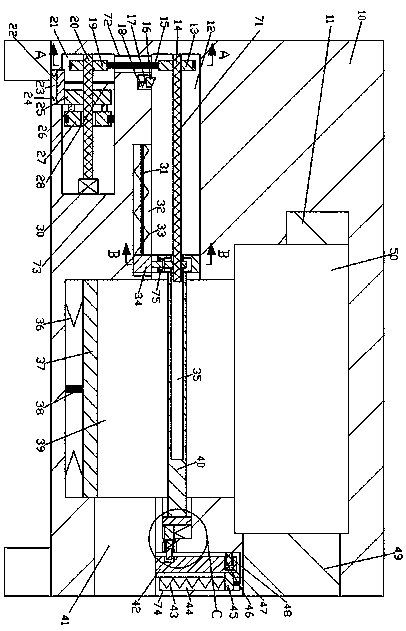

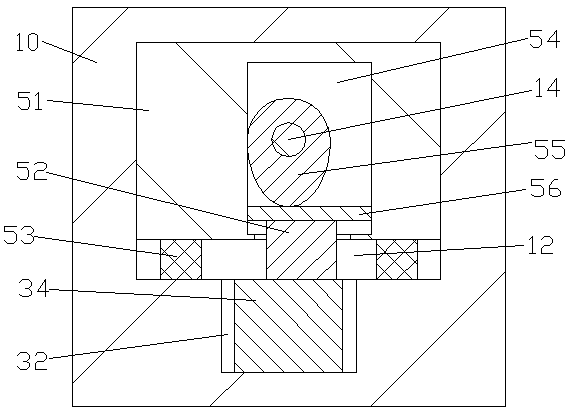

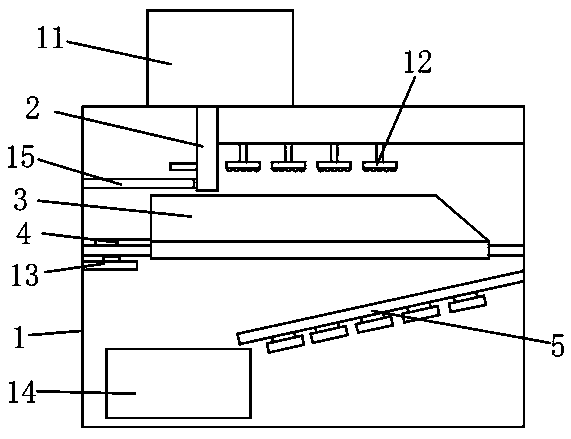

An automated high temperature environment test chamber

ActiveCN110465334BReduce exchangeChurn fastWeather/light/corrosion resistanceEnclosures/chambersThermodynamicsEngineering

The invention discloses an automated high-temperature environment test box, which comprises a test box, wherein a heating chamber with a rightward opening is arranged in the test box, a heat insulation glass for isolating the heating chamber and the external space is arranged in the heating chamber, a heat generation block is fixed on the left end wall of the heating chamber, a support chamber with an upward opening is arranged in the lower end wall of the heating chamber, a through chamber communicated to the external space and the support chamber is arranged in the right end wall of the support chamber, a cutting mechanism capable of sealing the through chamber is arranged in the upper end wall of the through chamber, and a moving chamber with a rightward opening is arranged in the leftend wall of the support chamber. According to the present invention, during the working of the automated high-temperature environment test box, when the object is taken out midway or finally, the heatexchange between the external space and the heating chamber can be reduced through the sealing of the sealing plate and the heat insulation plate so as to avoid the rapid heat loss in the heating chamber, such that the set temperature can be reached quickly when the next temperature rise is detected so as to save the energy.

Owner:东莞市赛准科技有限公司

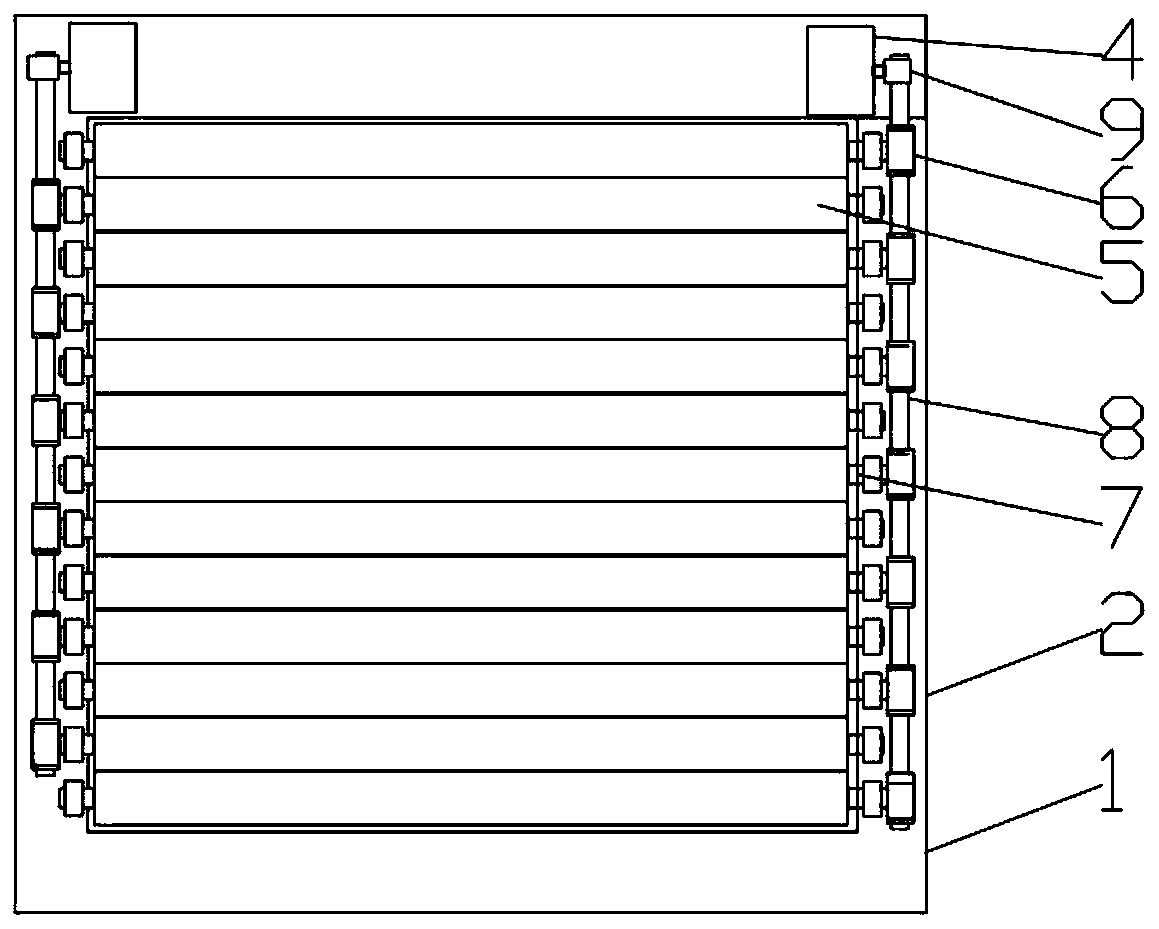

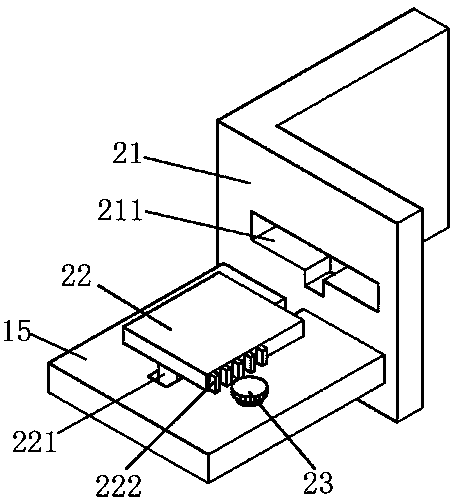

Sun-cured air drying room

ActiveCN110670919AChurn fastPrecise and labor-saving control adjustmentAgriculture tools and machinesAgricultural buildingsDrive shaftSprocket

The invention discloses a sun-cured air drying room. The room comprises a main body, wherein the main body comprises two parallel wall bodies, a transparent top plate is arranged at the top of the main body, a brightness adjusting device is arranged below the top plate, the brightness adjusting device comprises a motor, transmission chain wheels, transmission shafts, chains and a plurality of shading strips arranged in parallel, the transmission shafts are arranged at the two ends of each shading strip, the transmission shafts are connected with the main body through bearings, the transmissionchain wheels are arranged on the transmission shafts, a driving chain wheel is arranged on an output shaft of the motor, and the driving chain wheel is connected with the transmission chain wheels through the chains. According to the technical scheme, sunlight can enter the air drying room through the transparent top plate, the rotation angle of the shading strips is controlled through the motor,the area, shielding the sunlight, of the shading strips is changed, and the shielded area and the area irradiated by sunlight are alternated under the driving of the motor, so that the situation of too fast water losing caused by food exposure is prevented, and meanwhile, the control and adjustment are more accurate and labor-saving by adopting the motor.

Owner:溆浦县龙潭天然食品有限公司

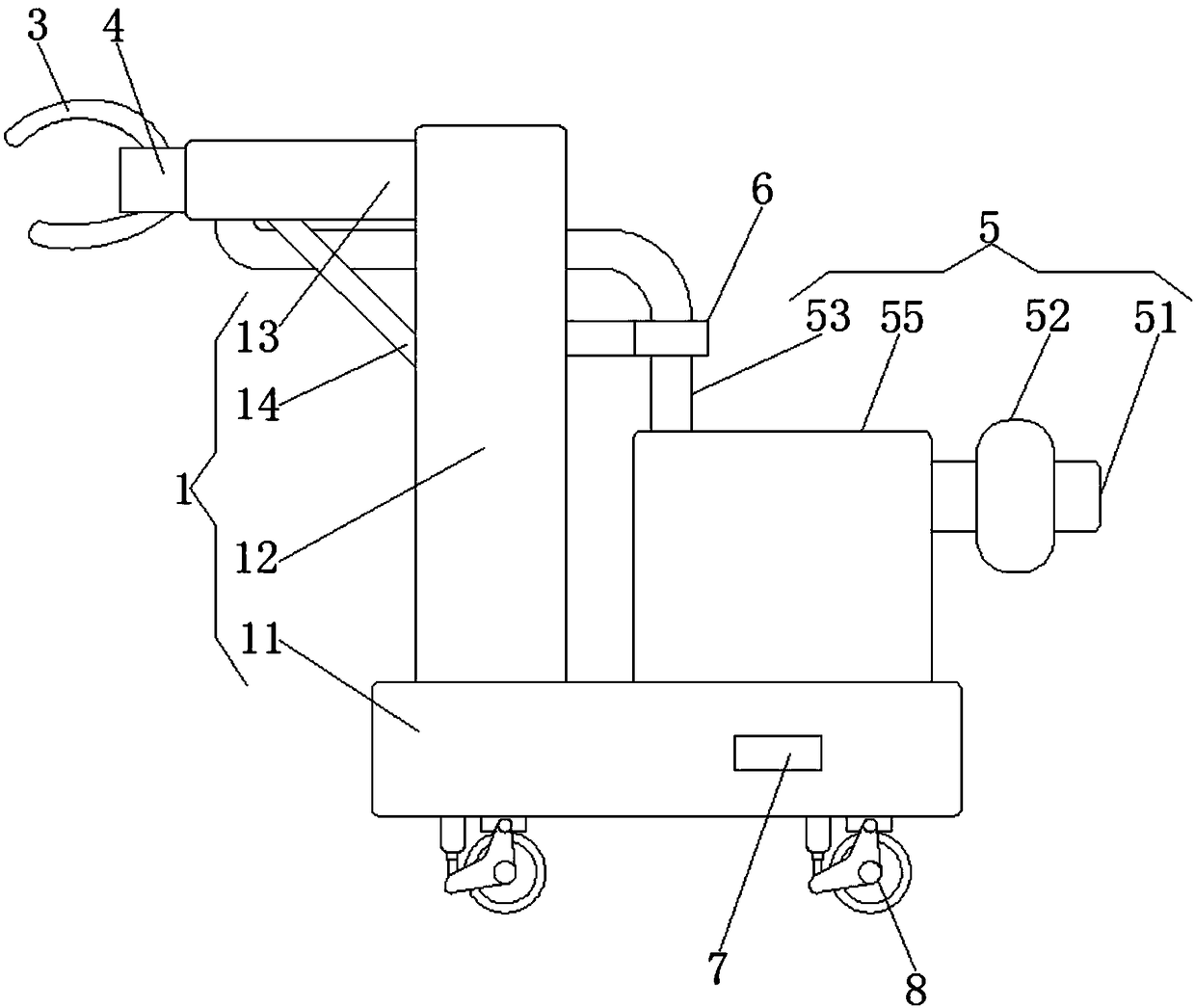

Joint health device for rheumatoid immunity

InactiveCN108272547AFirmly connectedPrevent leakageTherapeutic coolingTherapeutic heatingEngineeringBattery pack

The invention discloses a joint health device for rheumatoid immunity, and relates to the technical field of medical instruments. The joint health device for the rheumatoid immunity comprises a supporting mechanism, a heating mechanism and a physiotherapy mechanism, wherein the supporting mechanism is formed by connecting a base, a first supporting column, a second supporting column and a supporting rod together, the heating mechanism comprises a heating device, a sealing table and a battery pack, the direct center of the top of the sealing table is provided with a first opening, a first sealing ring is fixedly connected to the first opening, the direct center of the bottom of the sealing table is provided with a second opening, and a limited block is fixedly connected to the second opening. The joint health device for the rheumatoid immunity has the advantages that water in a water tank can be heated by the heating device, so that the water can turn into steam and be transported out through a transporting mechanism, a heating layer is hollow and communicated with a shunt tube, so that the physiotherapy mechanism can be fully filled with the steam, and the heating physiotherapy mechanism is balanced, so that hot compress can be conducted on patients' joints.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

Blueberry tissue culture seedling long-distance transport packaging method

InactiveCN104891043AAvoid damageAvoid churnWrappers shrinkageLiving organism packagingWater flowSeedling

The invention discloses a blueberry tissue culture seedling long-distance transport packaging method. A blueberry tissue culture seedling long-distance transport packaging device comprises a box body and a box cover; net partitions are arranged in the box body; the net partitions are laid flat on a protruding pad which is arranged at the bottom of the box body; the heat sealing on blueberry tissue culture seedling roots with matrixes can be implemented through local heating on a polyethylene composite film, the blueberry tissue culture seedling roots and the lower portions are encapsulated to avoid the loss of moisture, and root encapsulated blueberry tissue culture seedlings are placed on the net partitions respectively. According to the blueberry tissue culture seedling long-distance transport packaging method, the heat sealing on the blueberry tissue culture seedling roots can be implemented through the local heating on the polyethylene composite film so as to effective avoid the blueberry tissue culture seedling roots from being damaged during placement, meanwhile the too rapid water loss of the roots is avoided, and meanwhile the seedling retting and rotting caused by extrusion, water accumulation and the like is avoided due to the fact that the tissue culture seedlings are separated from the accumulated water at the box bottom.

Owner:凤阳金小岗农林科技产业发展有限公司

Method for preserving, sprouting and cultivating gold-rimmed nanmu seeds

InactiveCN107439090AImprove germination rateImprove survival rateCultivating equipmentsHorticulture methodsTemperature controlManagement process

The invention discloses a method for preserving, sprouting and cultivating gold-rimmed nanmu seeds. The cultivating method comprises the following steps: (1) collecting and treating the seeds; (2) preserving the seeds; (3) laying a seedbed; (4) sprouting; (5) sowing; (6) managing cultivation. According to the method, water and light are controlled in the whole process from the seed preservation to the cultivation management and a beneficial environmental condition is supplied for the sprouting growth of the gold-rimmed nanmu seeds. A water sprayer and a temperature control unit are adopted for guaranteeing the seed preservation and increasing the germination rate of the seeds in the reuse process; the sprouting is performed in a sprouting instrument, the comprehensive environment during sprouting is more effectively controlled and the germination rate of the seeds is increased; in the cultivation management process, the humidity, temperature and light are controlled, an excellent surviving environment is supplied and the survival rate is further increased.

Owner:重庆红池林农业开发有限公司

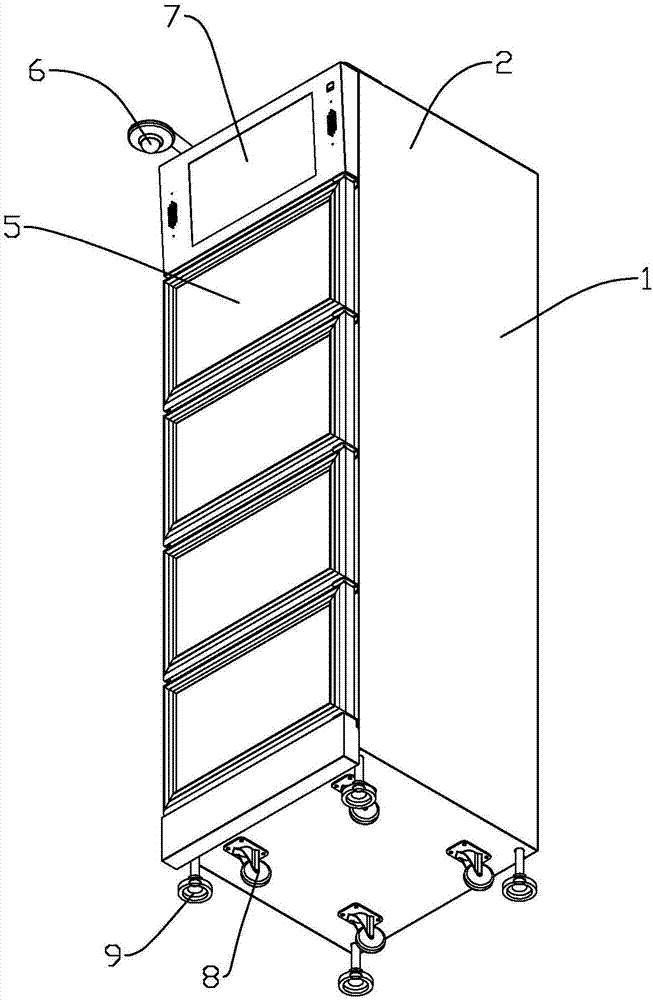

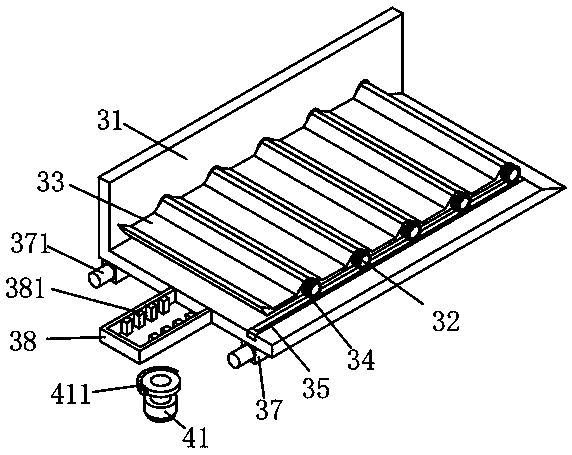

Drying machine with heat preserving function

ActiveCN109855399AAvoid wastingChurn fastDrying chambers/containersDrying machines with local agitationHeat conductingEngineering

The invention provides a drying machine with a heat preserving function. The drying machine comprises a box body, drying brackets, partition plates and a heating system. A heat preserving and heat insulating layer is arranged on the outer side of the box body. A metal layer is arranged on the outer side of the heat preserving and heat insulating layer. Rolling wheels are arranged on four corners of the bottom of the box body. The rolling wheels are universal wheels. The multiple partition plates are arranged in the height direction of the box body. The partition plates are arranged in the length direction of the box body. The partition plates comprise inner plates and outer plates. A containing cavity is formed in each outer plate. Each outer plate is arranged in the corresponding containing cavity. Each outer plate is provided with a plurality of first through holes in a penetrating manner. Each inner plate is provided with a plurality of second through holes. The inner plates and theouter plates are transversely connected in a sliding manner, and the first through holes can communicate or intersect. Each outer plate is provided with one drying bracket. The drying brackets and the outer plates are connected in a sliding manner. A sealing door plate is arranged at the front end of each drying bracket. The heating system comprises an oil pipe and a heat conducting oil furnace.The heat conducting oil furnace is arranged on the box body. An oil inlet and an oil outlet of the heat conducting oil furnace communicate with an oil pipe.

Owner:丽水市知源科技有限公司

Method for preparing siliconized graphite structure material

The invention discloses a method for preparing a siliconized graphite structure material. A nanoscale transition metal element is uniformly added into reduced graphite oxide through a graphite oxide hydrothermal method. When the transition metal element is used as a catalyst, the distribution is more uniform, the uniform formation of silicified graphite is facilitated, and meanwhile, the reactiontemperature and the reaction time are greatly reduced due to the high activity of a nanoscale material and the high catalytic performance of the transition metal. No vacuum protection or pressurization is needed in the reaction process, so that the reaction energy consumption is greatly reduced.

Owner:江苏嘉明碳素新材料有限公司

A hedgerow configuration method for light-potential rocky desertification environment in karst area

ActiveCN106612698BReduce churnIncrease coverageAgriculture gas emission reductionSoil-working methodsLand consolidationPyracantha fortuneana

Owner:GUIZHOU NORMAL UNIVERSITY

Ameliorant combination suitable for secondary saline-alkaline soil in irrigation areas of Yellow River

InactiveCN106336872AAvoid secondary salinizationSimple structureBiocideAgriculture tools and machinesSlagAdditive ingredient

The invention discloses an ameliorant combination suitable for secondary saline-alkaline soil in irrigation areas of the Yellow River. The ameliorant combination comprises, by weight, 120-180 parts of a soil loosening agent, 250-400 parts of citric acid residue, 160-200 parts of diatomite of 1,250-2,000 meshes, 120-160 parts of ammonium molybdate, 80-120 parts of sodium selenite, 30-60 parts of seaweed slag, 8-20 parts of straw ash, 800-1,200 parts of coconut residuum and 10-14 parts of microbes. The soil loosening agent is a mixture obtained by crushing peat, dry pine needle, vermiculite, natural zeolite and peanut shell according to the mass ratio of 5:3:1:2:1. According to the ameliorant combination suitable for secondary saline-alkaline soil in irrigation areas of the Yellow River, various nutritional ingredients are reasonably cooperated, and various components are combined mutually, influence each other and coordinate with each other. Then, soil secondary saline-alkalization caused by random fertilization can be avoided.

Owner:SHANDONG SUNWAY LANDSCAPE TECH

A reversible food processing and drying device

ActiveCN109028904BChurn fastDry evenlyDrying gas arrangementsDrying solid materialsBiotechnologyEngineering

The invention provides a turnover type food processing and drying device. The turnover type food processing and drying device comprises a drying box and a material storage box fixedly connected abovethe drying box, a material guide device is arranged below the material storage box, a turnover type drying device is arranged in the drying box, below the material guide device, a plurality of ceramicheating lamps are arranged above the turnover type drying device, a vibrating device is arranged on one side of the turnover type drying device, a first supporting plate is arranged in the drying box, the vibrating device is fixedly connected with the first supporting plate and is far away from one side of the vibrating device, a wind power drying device is arranged in the drying box, the wind power drying device is obliquely arranged, in the drying box, and a material collecting box is arranged in the drying box.

Owner:安徽佰味葫芦电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com