Cylindrical heat source thermoelectric generation device

A thermoelectric power generation, cylinder technology, applied in the directions of generators/motors, electrical components, etc., can solve the problems of small contact area, insignificant effect, increase generator monomers, etc., to reduce the process of heat conduction and speed up the cold end Heat dissipation and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

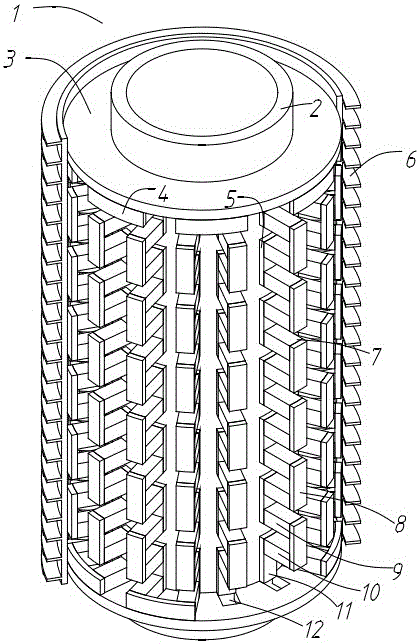

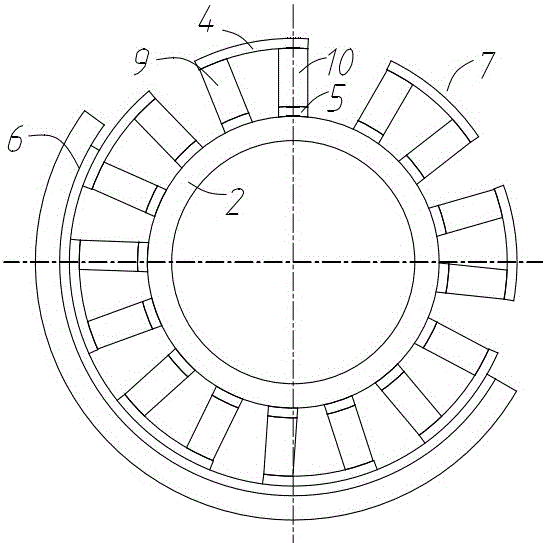

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only for the present invention but not intended to limit the scope of the present invention. It should be noted that, in order to facilitate the display of the device structure, the size of the illustration is not the same as that of the actual device, nor is it proportional.

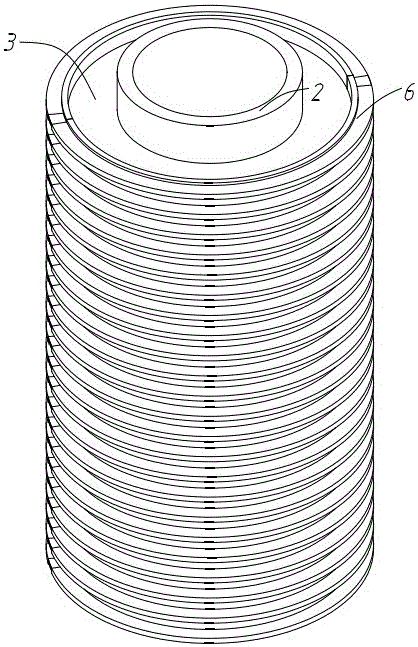

[0017] Such as figure 1 with figure 2 As shown, the cylindrical heat source thermoelectric power generation device 1 of the present invention is installed on the heat source outer wall 2 of a cylinder, including a plurality of P-type semiconductors 9, N-type semiconductors 10, hot-end conductive sheets 5 and cold-end conductive sheets 8, a plurality of P-type semiconductors 9 and N-type semiconductors 10 are connected in series through a plurality of cold-end conductive sheets 8 and hot-end conductive sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com