Drying machine with heat preserving function

A drying machine and functional technology, applied in the direction of drying machine, static material drying machine, drying, etc., can solve the problems of heat loss, waste of energy, etc., to avoid heat waste, improve uniformity and efficiency, and avoid heat loss Effects that drain too quickly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiment:

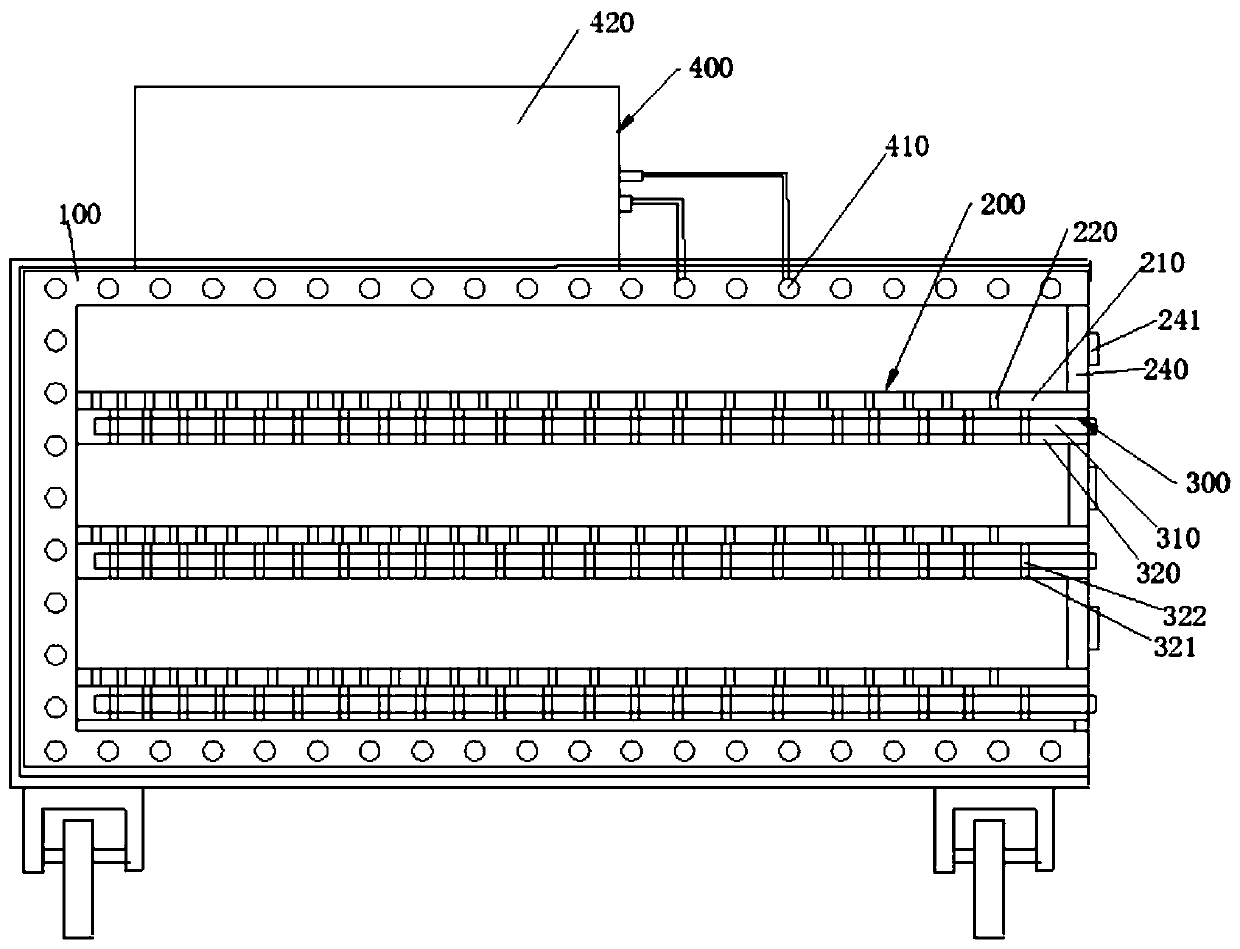

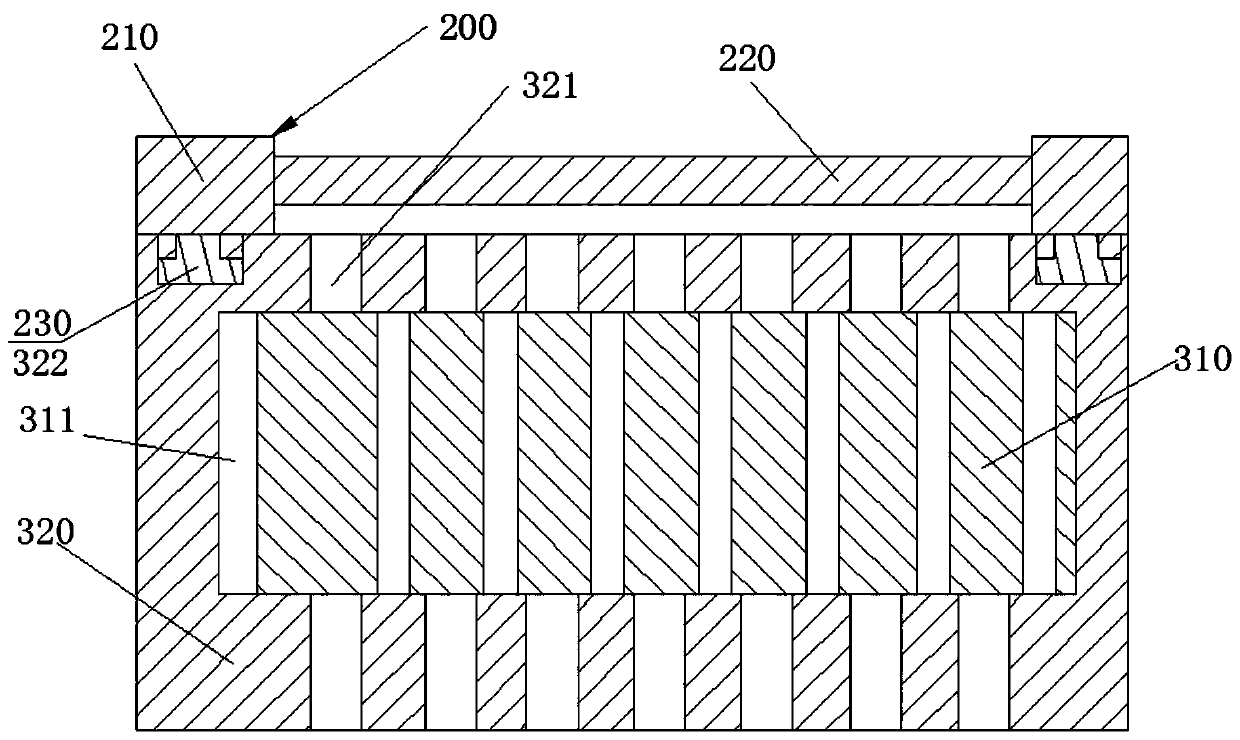

[0016] Such as figure 1 and figure 2 As shown, a dryer with heat preservation function includes a box body 100, a drying bracket 200, a partition plate 300, and a heating system 400. The outer side of the box body 100 is provided with a heat insulation layer 110, and the heat insulation layer 110 A metal layer 120 is provided on the outside, and four corners of the bottom of the box body 100 are provided with rollers 130, which are universal wheels, and a plurality of partition plates 300 are arranged along the height direction of the box body 100, and the partition plates 300 are arranged along the The reading direction of 100 is set. The partition plate 300 includes an inner plate 310 and an outer plate 320. The outer plate 320 is provided with an accommodation cavity. The outer plate 320 is arranged in the accommodation cavity. The inner plate 310 is provided with a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com