Sintering ignition furnace and ignition control process thereof

A technology of ignition control and sintering point, which is applied in the direction of furnace, burner, furnace type, etc., can solve the problems of poor ignition effect and easy over-melting of material surface, etc., and achieve the effect of ensuring ignition intensity and enhancing side ignition intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

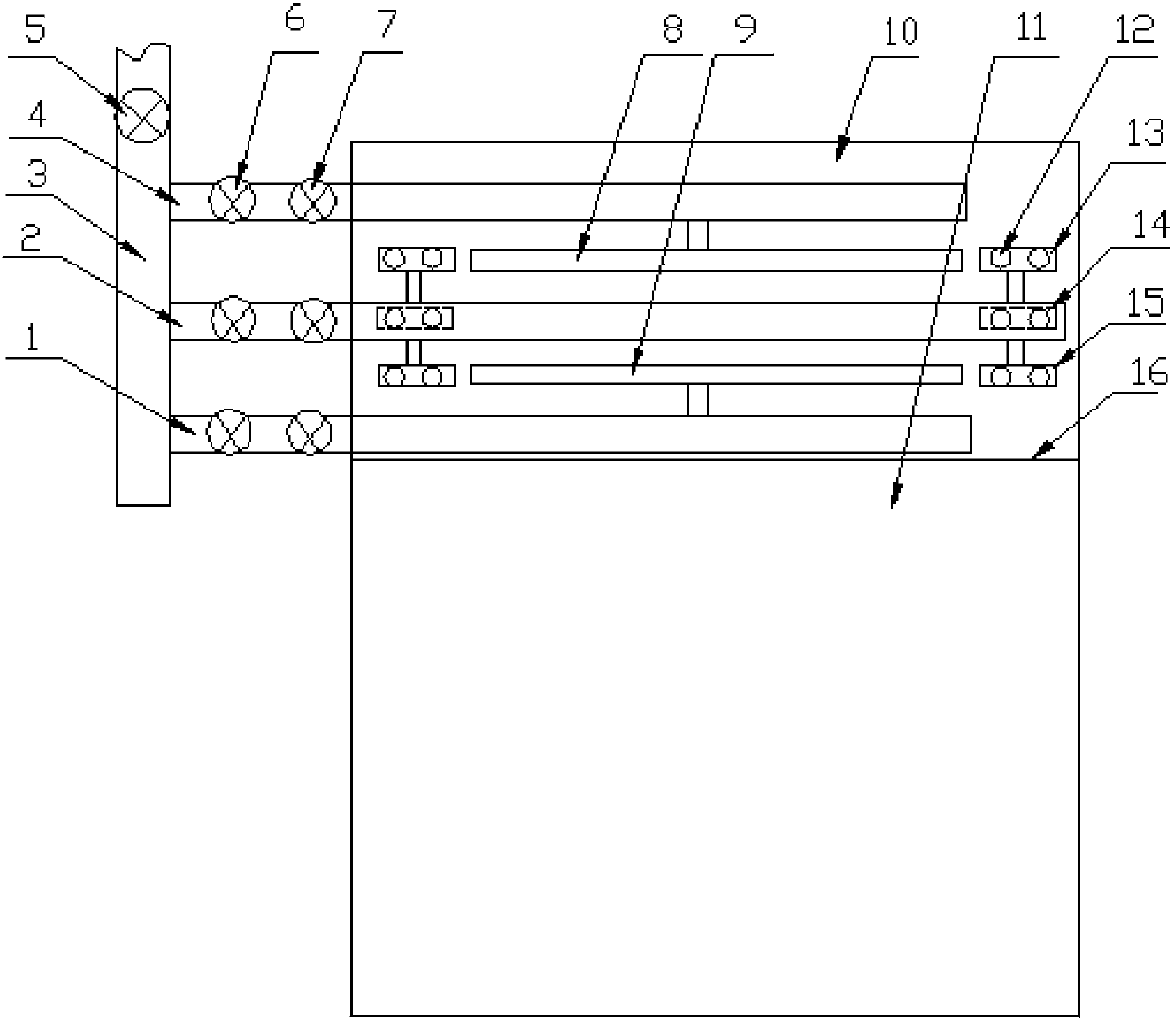

[0031] A sintering ignition furnace includes an ignition chamber 10, and more than one row of side burner gas pipes 2 are added in the ignition chamber 10, and several rows of side burner gas pipes 2 are provided at both ends of the side burner gas pipes 12. The side burner gas pipe 2 is no longer provided with a burner, relying on the ignition intensity of other gas pipe consoles in the middle of the car, and several groups of side burners 12 provided at both ends of the side burner gas pipe 2 are for the two sides of the trolley. Zone ignition to enhance the intensity of side ignition and control the effect of edge ignition on both sides.

Embodiment 2

[0033] A sintering ignition furnace, each row of side burners 12 has one or more pieces, all of which are connected to the side burner gas pipes 2 . The number of side burners 12 in each row can be determined according to the specific working conditions on site. Each row of side burners 12 is arranged along the lateral direction of the edge areas on both sides of the trolley, which can finally ensure the lateral direction of the edge area of the trolley. , to enhance the side ignition intensity and control the edge ignition effect on both sides.

Embodiment 3

[0035] A sintering ignition furnace has one or more rows of side burners 12 in total, all of which are in communication with gas pipes 2 of the side burners. The number of rows of side burners 12 can be determined according to the specific working conditions on site. Each row of side burners 12 is arranged along the longitudinal direction of the edge areas on both sides of the trolley, which can finally ensure the longitudinal direction of the edge areas of the trolley. Enhance the side ignition intensity and control the edge ignition effect on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com