Method for preparing large-size aluminum oxide-yttrium aluminum garnet eutectic ceramic through horizontal orientation zone melting crystallization

A yttrium aluminum garnet, horizontally oriented technology is applied in the field of preparing alumina-yttrium aluminum garnet eutectic ceramics, which can solve the problems of poor eutectic quality and many growth defects, and achieves large size, large action area, room temperature and temperature. Outstanding high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

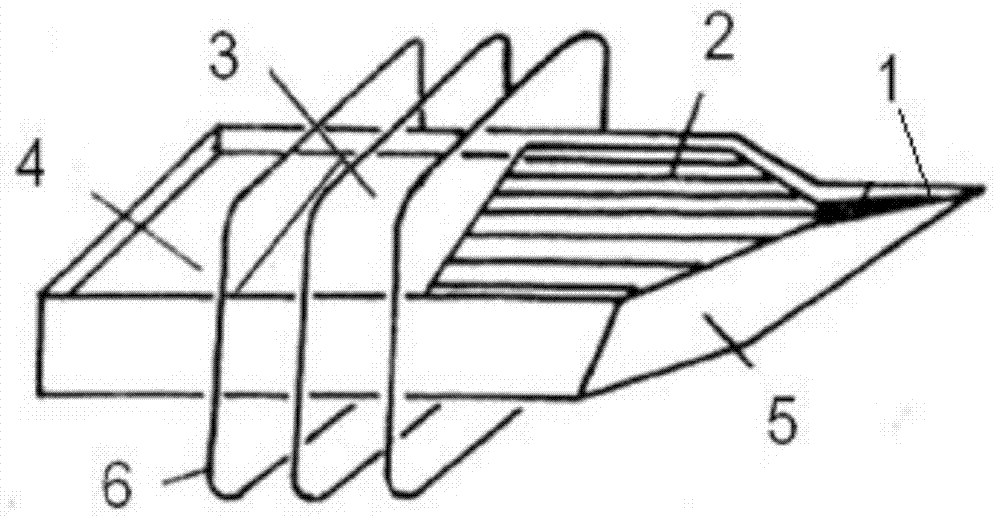

[0018] Specific implementation mode 1: In this implementation mode, a method for preparing large-scale alumina-yttrium aluminum garnet eutectic ceramics by melting and crystallizing in a horizontal orientation zone is carried out according to the following steps:

[0019] 1. Mixing of ceramic materials: Weigh 81.5mol% Al according to molar ratio 2 o 3 and 18.5 mol% of Y 2 o 3 , mixed to obtain the mixture, then wet ball milled with ethanol for 5h to 12h, dried, put into a cylindrical plastic mold, and pressed into a rod body of φ30mm×150mm by cold isostatic pressing with a hydraulic press, and sintered at high temperature in an air atmosphere, the sintering temperature The temperature is 1500°C, the sintering time is 5h-10h, and the rod-shaped raw material 4 is obtained;

[0020] 2. Chemical material: Wash the molybdenum boat-shaped crucible 3 to 5 times with alcohol, then vertically embed the YAG seed crystal 1 into the tip of the cleaned molybdenum boat-shaped crucible 4,...

specific Embodiment approach 2

[0032] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the sintering time in step 1 is 8 hours. Others are the same as the first embodiment.

specific Embodiment approach 3

[0033] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the heating element 6 in step 2 is a welded tungsten heating element; the heating element 6 is a flat box type. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com