Method for preparing Cr/CrN/Cu-TiN film on surface of stainless steel operation instrument

A surgical instrument, stainless steel technology, applied in the field of thin film preparation on the surface of stainless steel instruments, can solve the problems of unclean cleaning, incomplete disinfection and sterilization, etc., and achieve the effect of cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

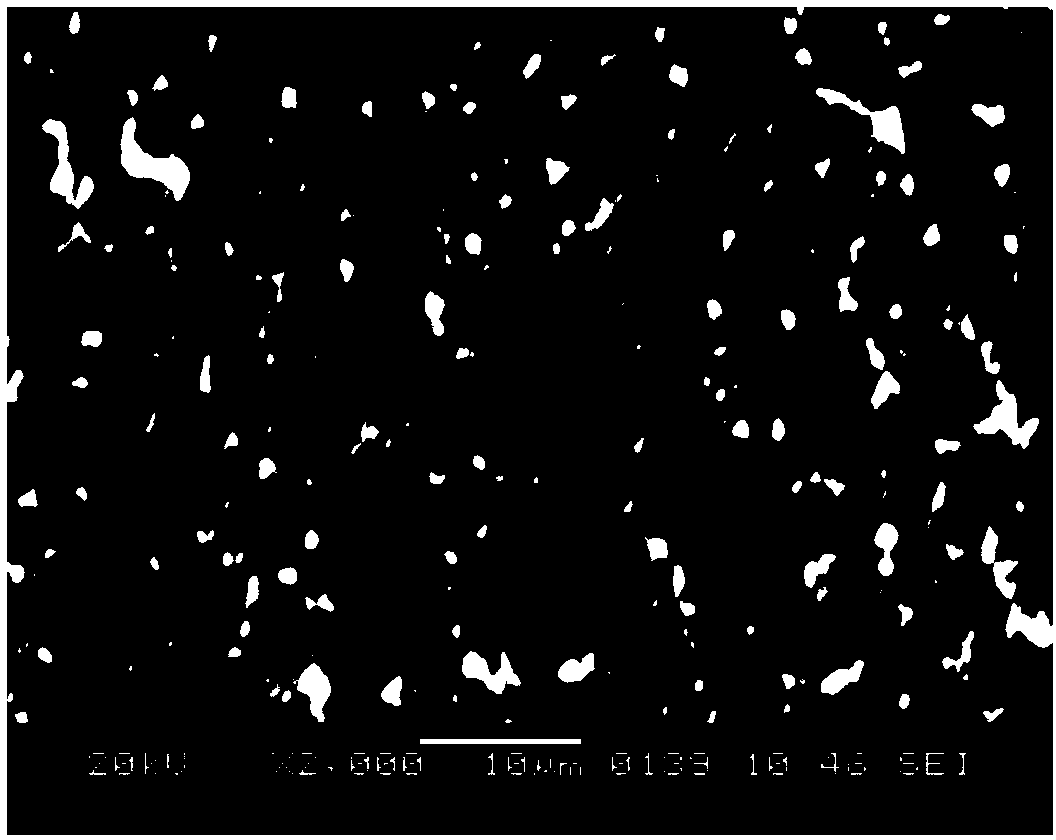

Image

Examples

specific Embodiment approach 1

[0019] Embodiment 1: This embodiment is a method for preparing a Cr / CrN / Cu-TiN film on the surface of a stainless steel surgical instrument, specifically as follows:

[0020] 1. Ultrasonic cleaning: First, use sodium hydroxide aqueous solution with a concentration of 40g / L as the cleaning agent at an ultrasonic frequency of 40kHz to ultrasonically clean the stainless steel surgical instruments for 10 minutes to 20 minutes, and then use alcohol with a mass fraction of ≥99.7% as the cleaning agent in the ultrasonic cleaning Ultrasonic cleaning at a frequency of 40kHz for 10min to 20min, and finally using distilled water as a cleaning agent at an ultrasonic frequency of 40kHz for 5min to 15min to obtain cleaned stainless steel surgical instruments;

[0021] 2. Chemical etching: immerse the cleaned stainless steel surgical instrument in the etching solution, etch for 5 minutes to 15 minutes, and then wash it with distilled water until the black substance on the surface of the stain...

specific Embodiment approach 2

[0027] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the stainless steel surgical instrument described in step 1 is a scalpel handle, surgical scissors, surgical forceps or surgical forceps. Others are the same as the first embodiment.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step one, at first, the sodium hydroxide aqueous solution with a concentration of 40g / L is used as a cleaning agent at an ultrasonic frequency of 40kHz to perform ultrasonication on stainless steel surgical instruments Wash for 15 minutes, then use alcohol with mass fraction ≥ 99.7% as cleaning agent, ultrasonically clean at an ultrasonic frequency of 40 kHz for 15 minutes, and finally use distilled water as a cleaning agent to ultrasonically clean at an ultrasonic frequency of 40 kHz for 10 minutes to obtain cleaned stainless steel surgical instruments. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com