Micro arc ion plating surface treatment method for flexible gear for harmonic reducer

A technology of micro-arc ion plating and harmonic reducer, which is applied in the field of material manufacturing, can solve problems such as poor precision, insufficient product durability, and low fatigue and wear life of gear teeth, so as to avoid metal droplets, reduce wear and fatigue damage , the effect of low friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

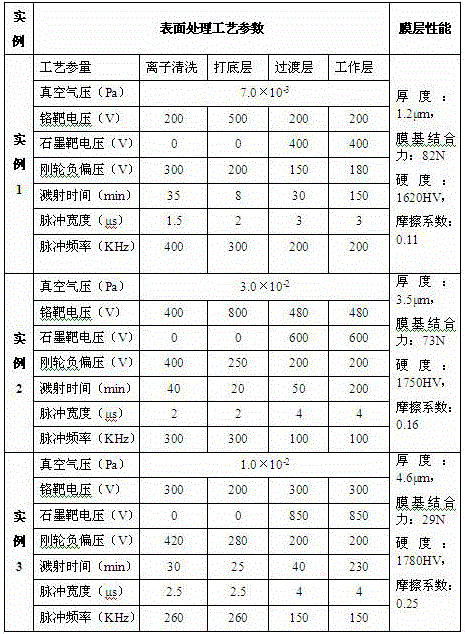

Examples

Embodiment Construction

[0022] The specific implementation is as follows:

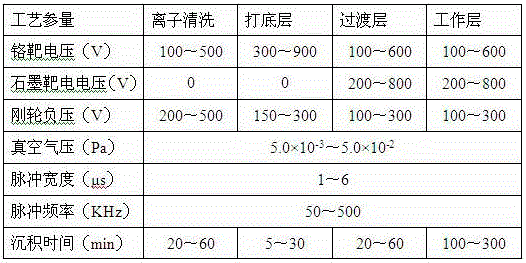

[0023] A micro-arc ion plating surface treatment method for a flexible gear used in a harmonic reducer. An amorphous carbon coating with a thickness of 0.3 μm to 5 μm is prepared on the surface of the flexible gear. The coating has a hardness of 1200HV to 2000HV and a friction coefficient of 0.08 to 0.20, including Follow the steps below:

[0024] Step 1: Vacuum

[0025] First, take the flexible gear to be processed and clean it through ultrasonic dewaxing and degreasing, then use 0.5MPa~5MPa high-pressure air to dry the cleaned flexible gear, put the dried flexible gear into the four-target micro The arc ion plating equipment is placed in the vacuum chamber of the arc ion plating equipment and installed on the work plate. Two chromium targets and two graphite targets are placed in the vacuum chamber, and the vacuum chamber is vacuumed to make the vacuum chamber reach less than 3.0×10 -3 The vacuum degree of Pa is to pass a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com