Patents

Literature

69 results about "Devices vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

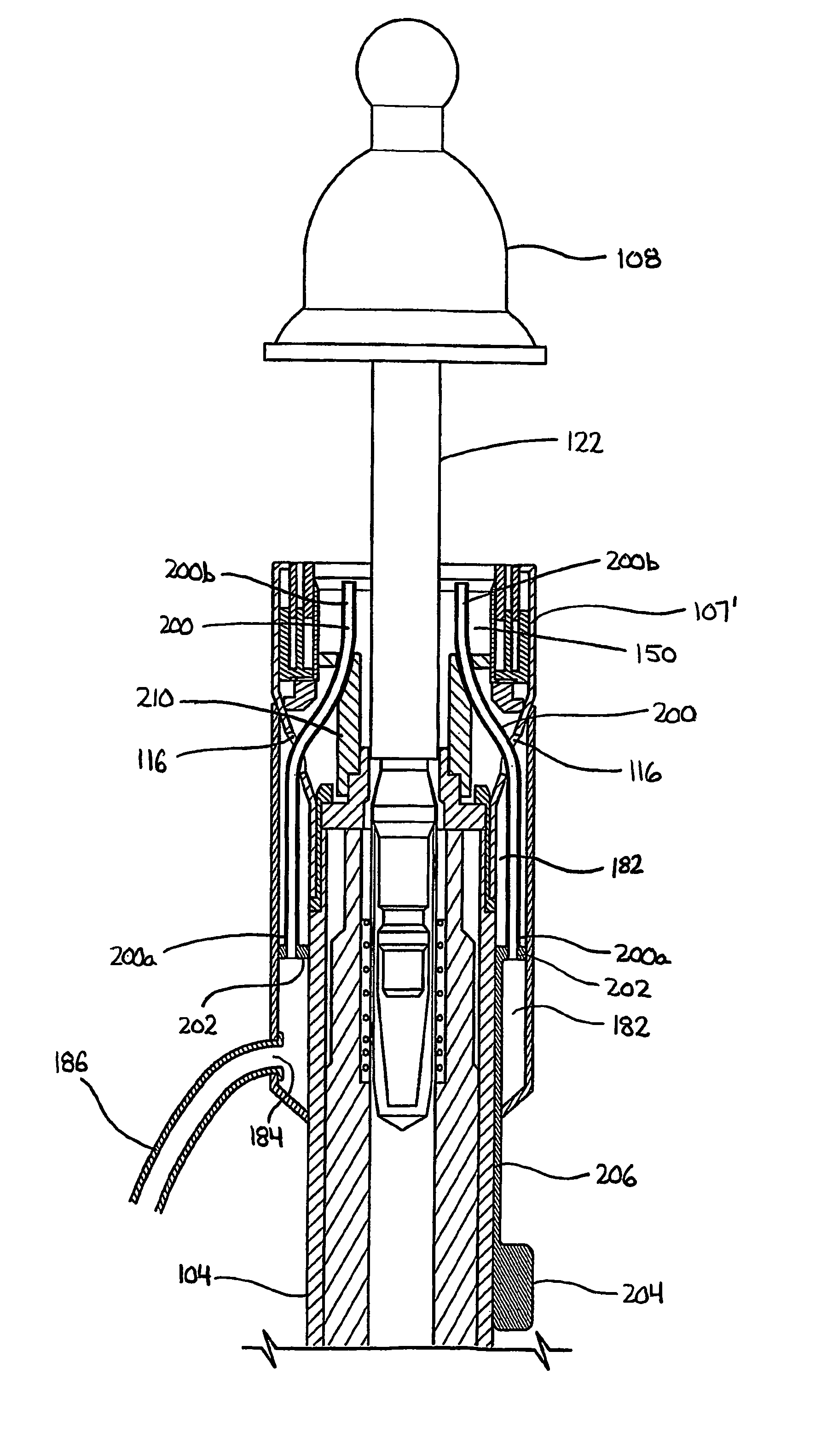

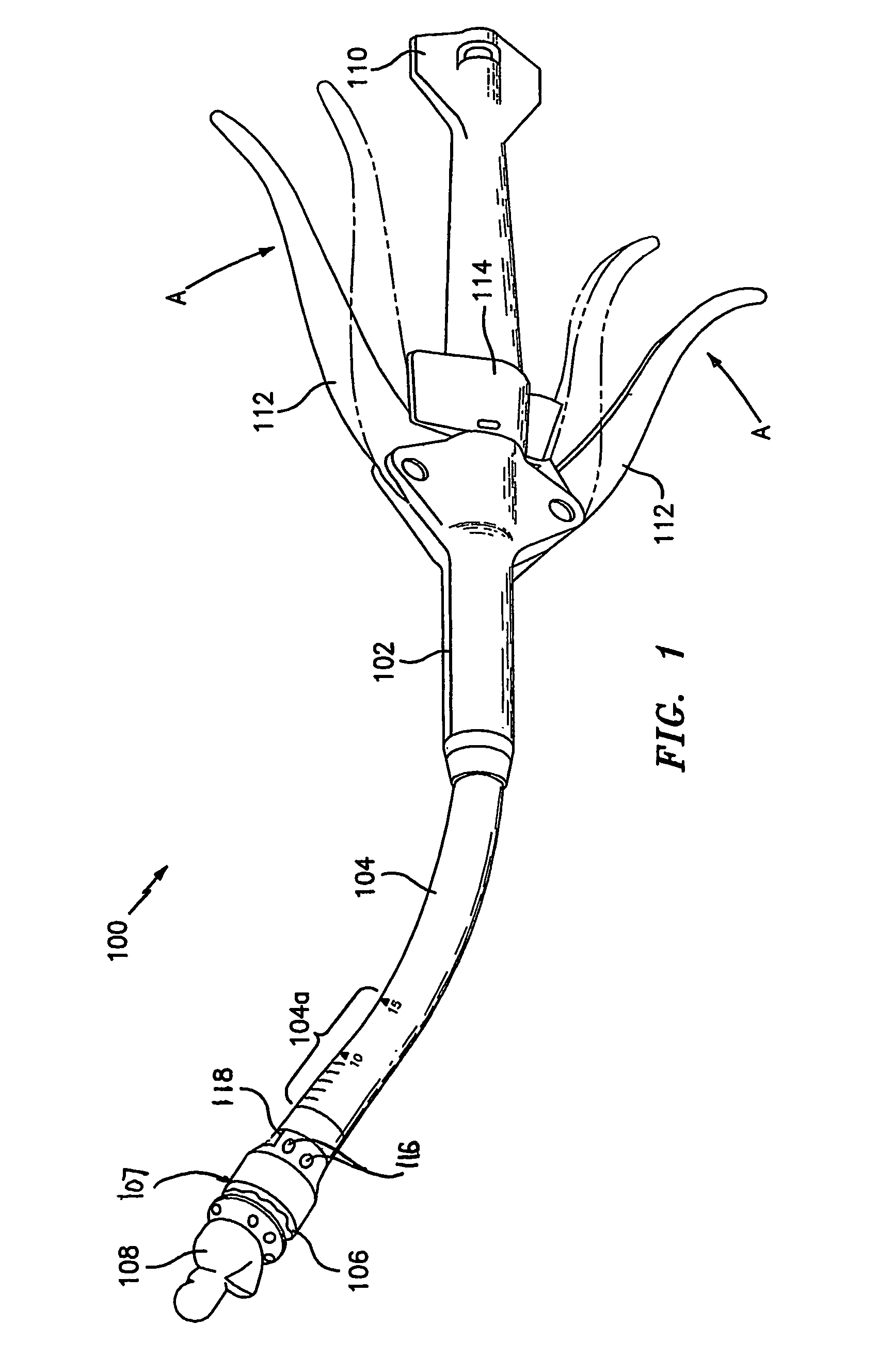

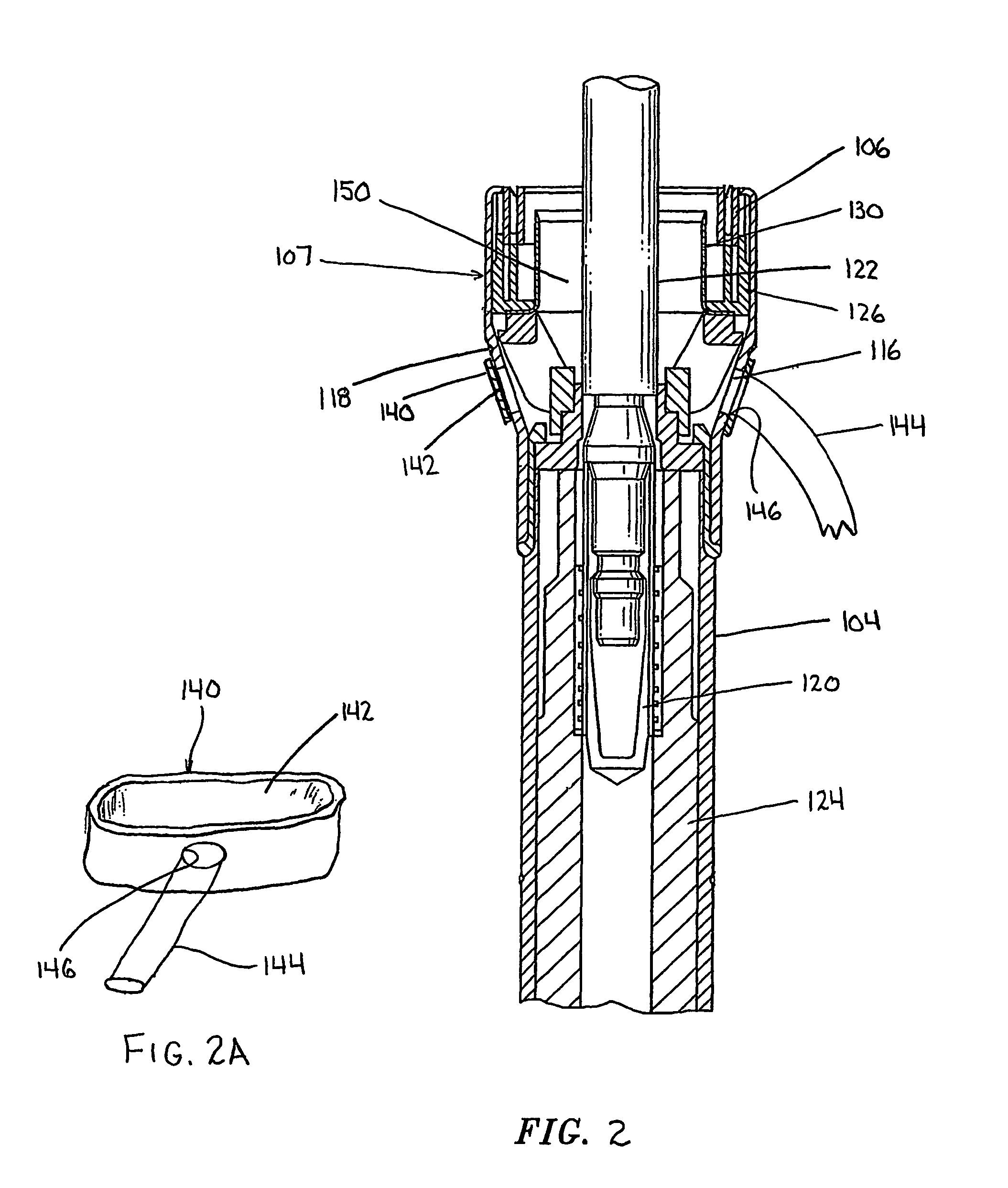

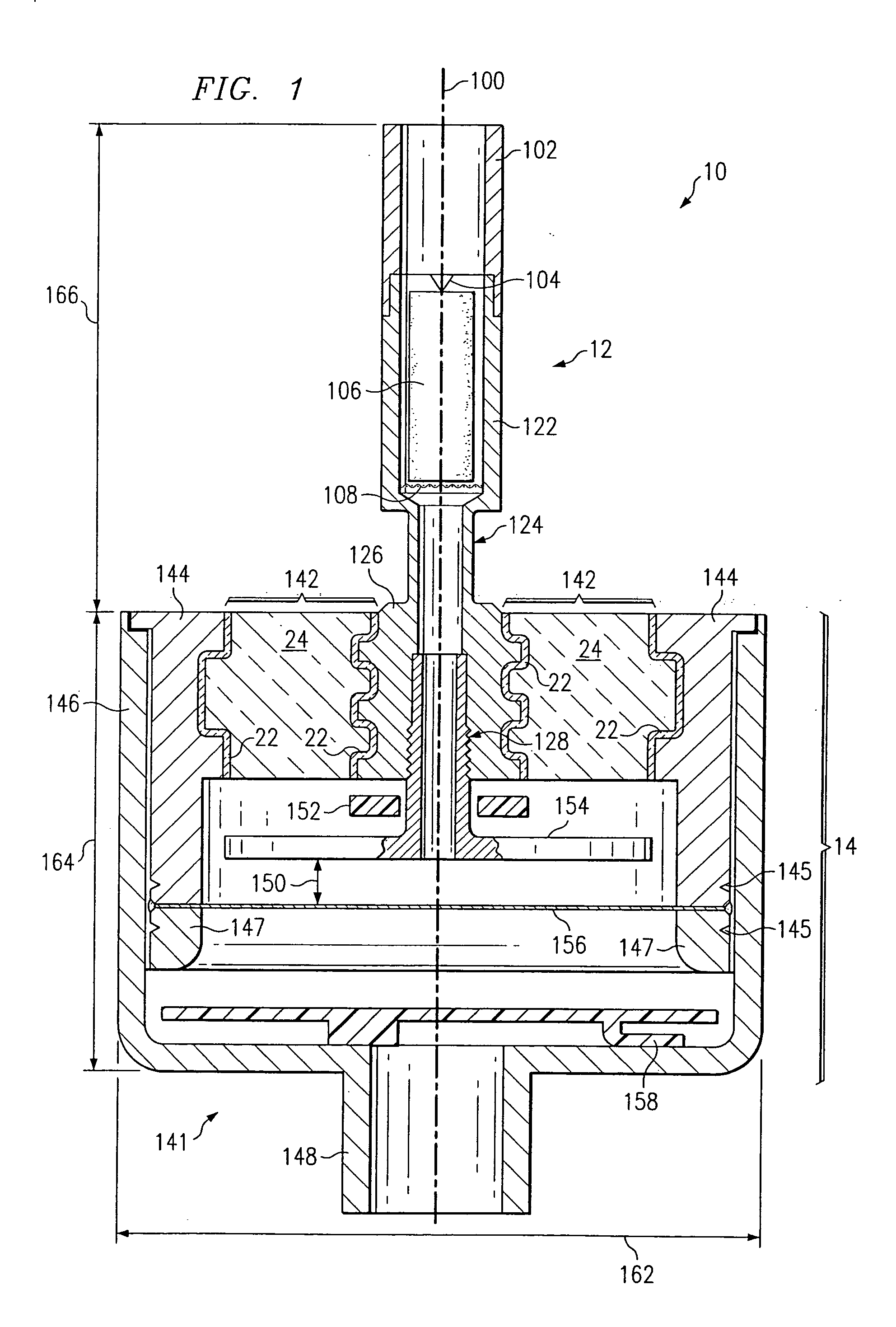

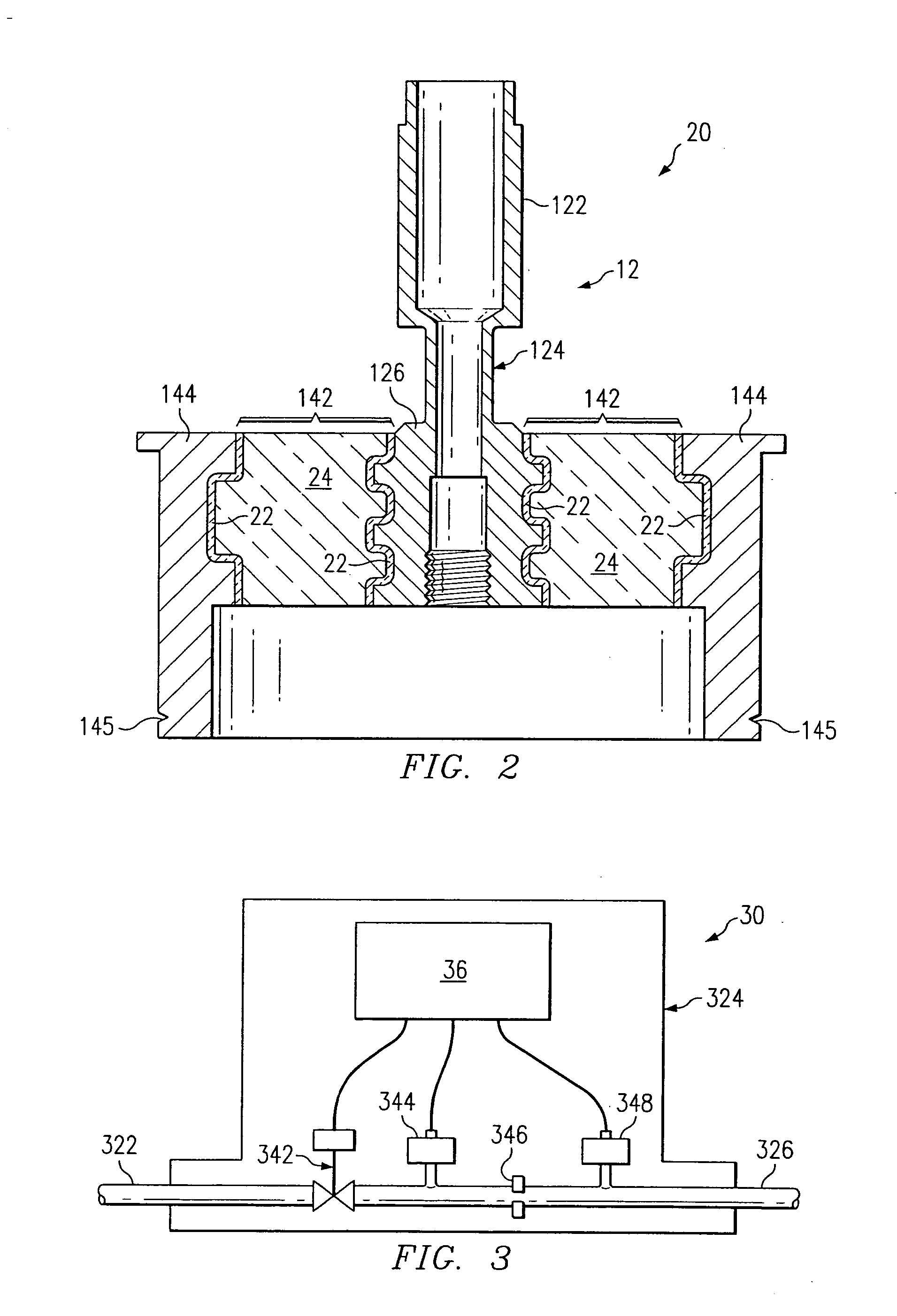

Vacuum assisted surgical stapler

A surgical stapling apparatus having a vacuum device associated therewith is disclosed. The vacuum device may be removable, fixedly secured thereto, or incorporated into the surgical stapling apparatus. The vacuum device may include a resilient band and vacuum tube secured to the shell assembly or body portion of the surgical stapling apparatus. Alternately, a vacuum chamber may be secured about the shell assembly and / or body portion of the stapling apparatus. In addition, one or more vacuum tubes may be positioned in the vacuum chamber. The vacuum tubes, preferably, extend into the shell assembly and are movable between nondeployed and deployed positions such that a distal end of each tube can be selectively positioned at multiple positions between the shell assembly and an anvil. The vacuum tubes can be formed of a shape-memory material such that the tubes point radially outwardly of the shell assembly when the tubes are in the deployed position.

Owner:TYCO HEALTHCARE GRP LP

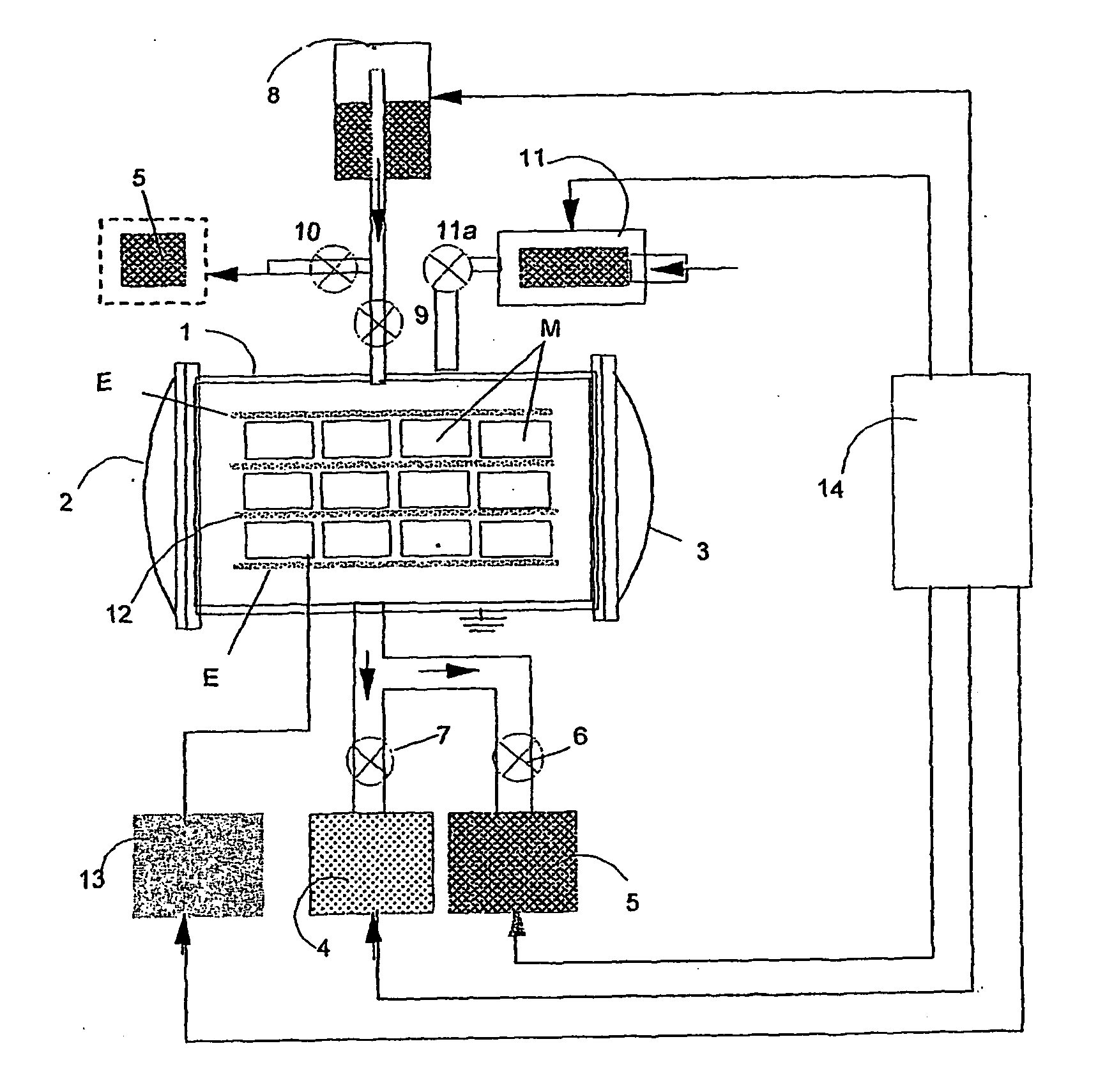

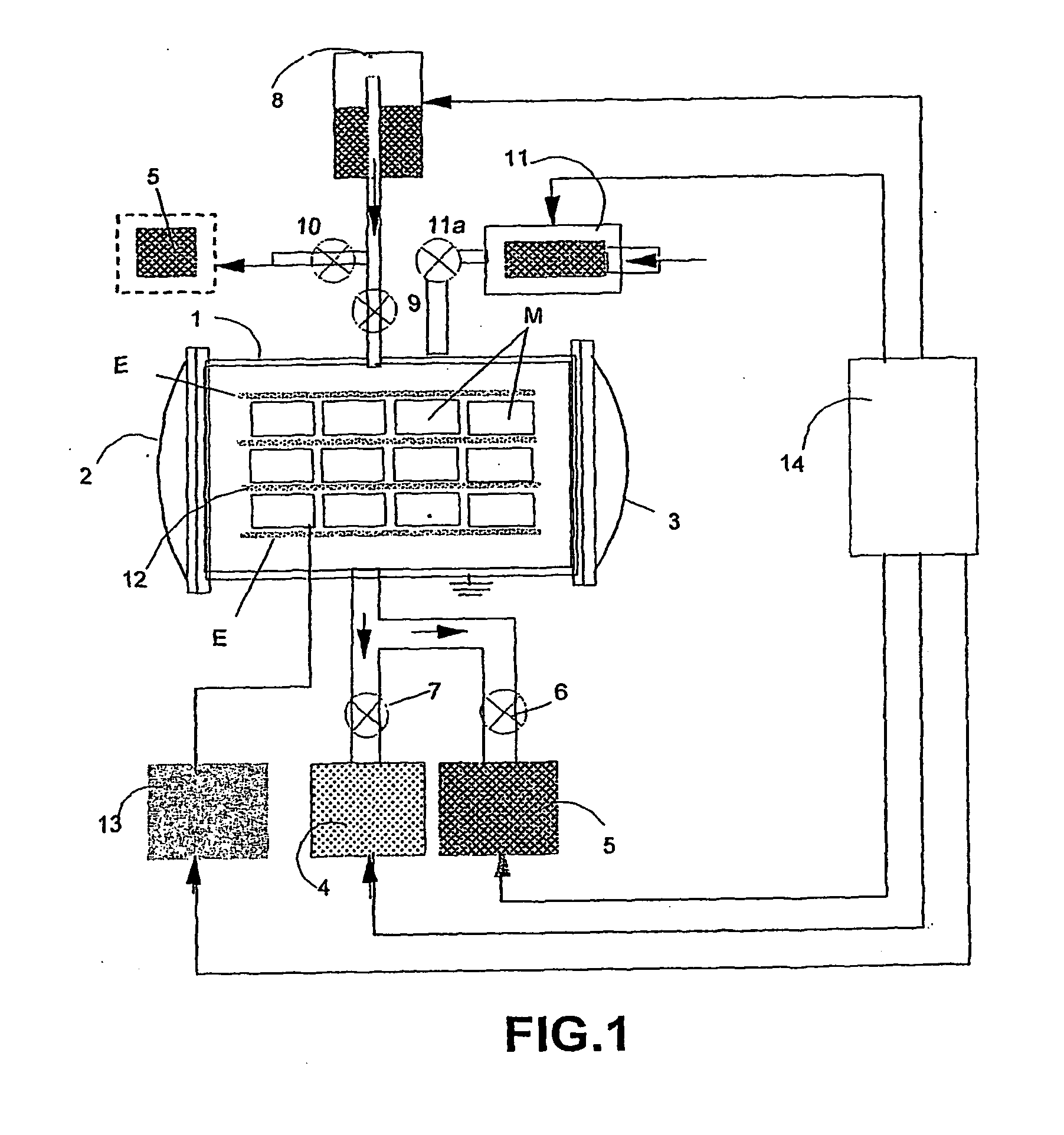

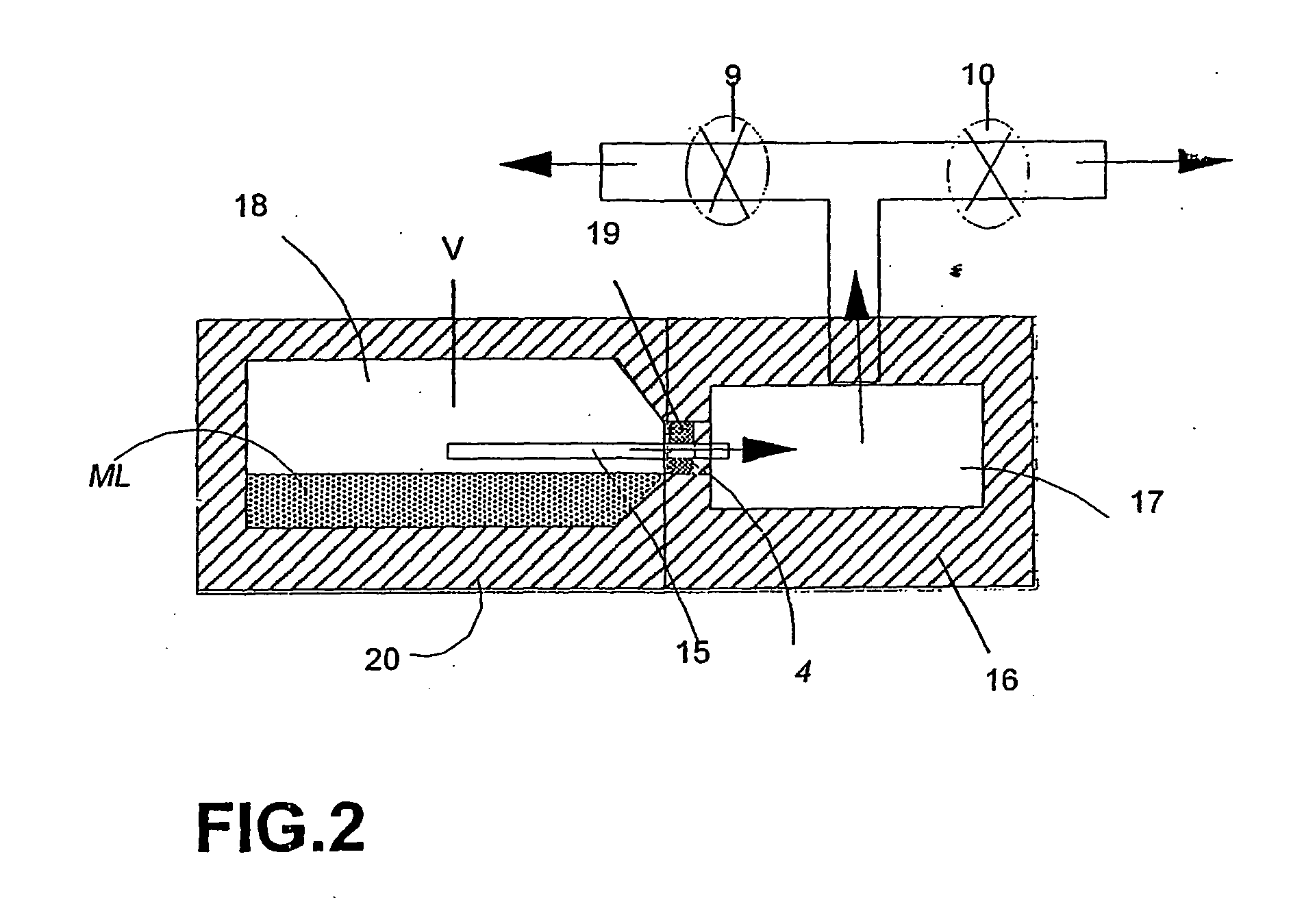

Vacuum sterilization process and devices

InactiveUS20060280646A1Improve efficiencyControlled diffusionLavatory sanitoryChemicalsAtmospheric airPhysical chemistry

Vacuum sterilization process with the application of vapour of a mixture of peracetic acid with hydrogen peroxide and residual gas plasma from atmospheric air, excited by pulsed electrical discharge; operational devices and methods used in the sterilization process, preferably a process of sterilization in vacuum, dry, and at low temperature (room temperature).

Owner:CISA

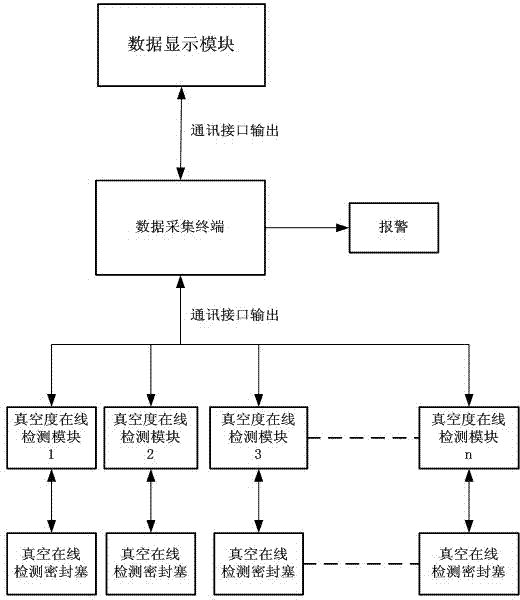

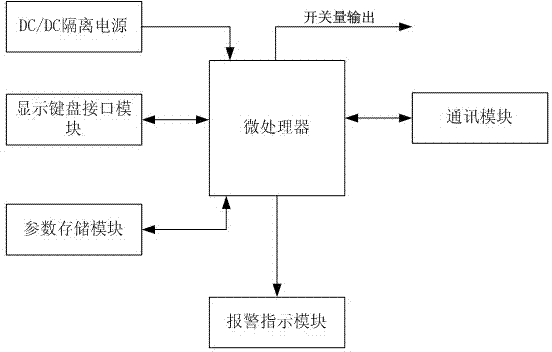

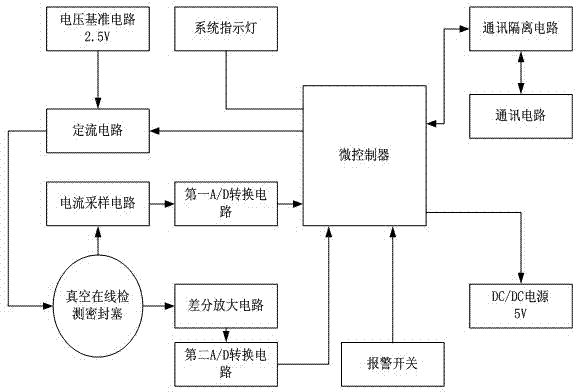

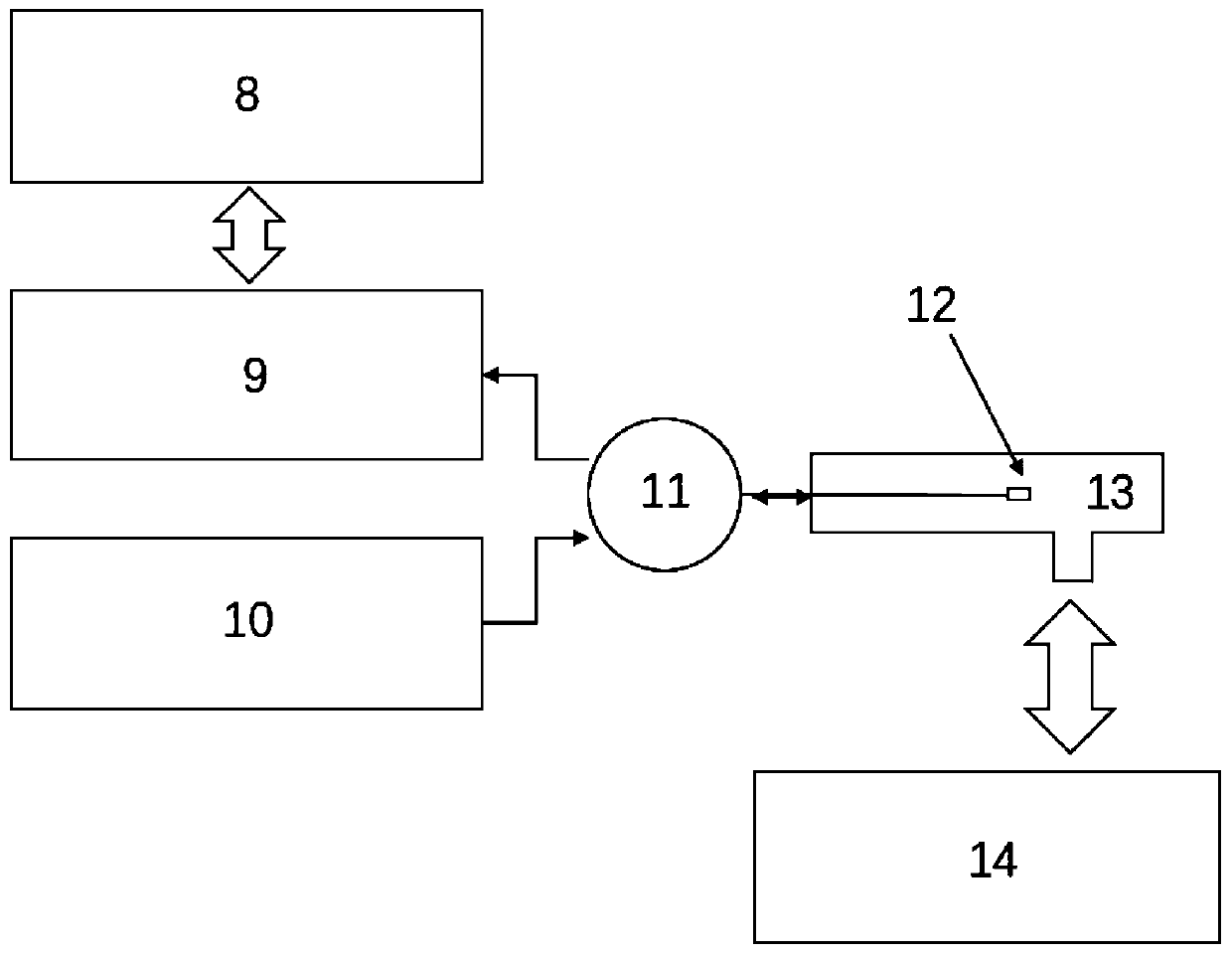

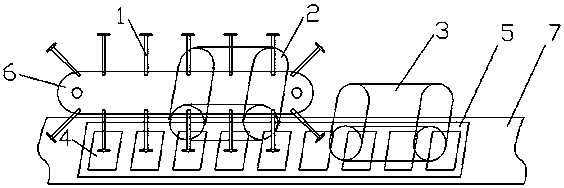

Vacuum degree on-line detecting system

InactiveCN103196628APlay a role in preventing potential safety hazardsReduced chance of vacuum leaksVacuum gauge using heat conductivity variationData displayData acquisition

The invention discloses a vacuum degree on-line detecting system which comprises a display module, a data collection terminal, a vacuum degree on-line detecting module and a vacuum on-line detecting sealing plug, wherein the vacuum on-line detecting sealing plug is used for obtaining vacuum data of vacuum equipment, the vacuum degree on-line detecting module is used for processing the vacuum data obtained by the vacuum on-line detecting sealing plug so that the vacuum degree of a vacuum layer of the vacuum equipment is obtained, and the data collecting terminal is used for obtaining vacuum degree data which is sent by at least one vacuum degree on-line detecting module and conducting alarm notification and / or outputting a signal which can control the vacuum equipment to be shut down according to a comparing result of the vacuum degree data and the preset vacuum degree parameter. The vacuum degree on-line detecting system has the advantages of achieving on-line detection of the vacuum degree of the vacuum equipment, detecting a plurality of targets, effectively playing a role in preventing safety hazard, reducing the rate of vacuum leaking and accidents of the equipment, and guaranteeing the using safety.

Owner:成都倍特科技有限责任公司

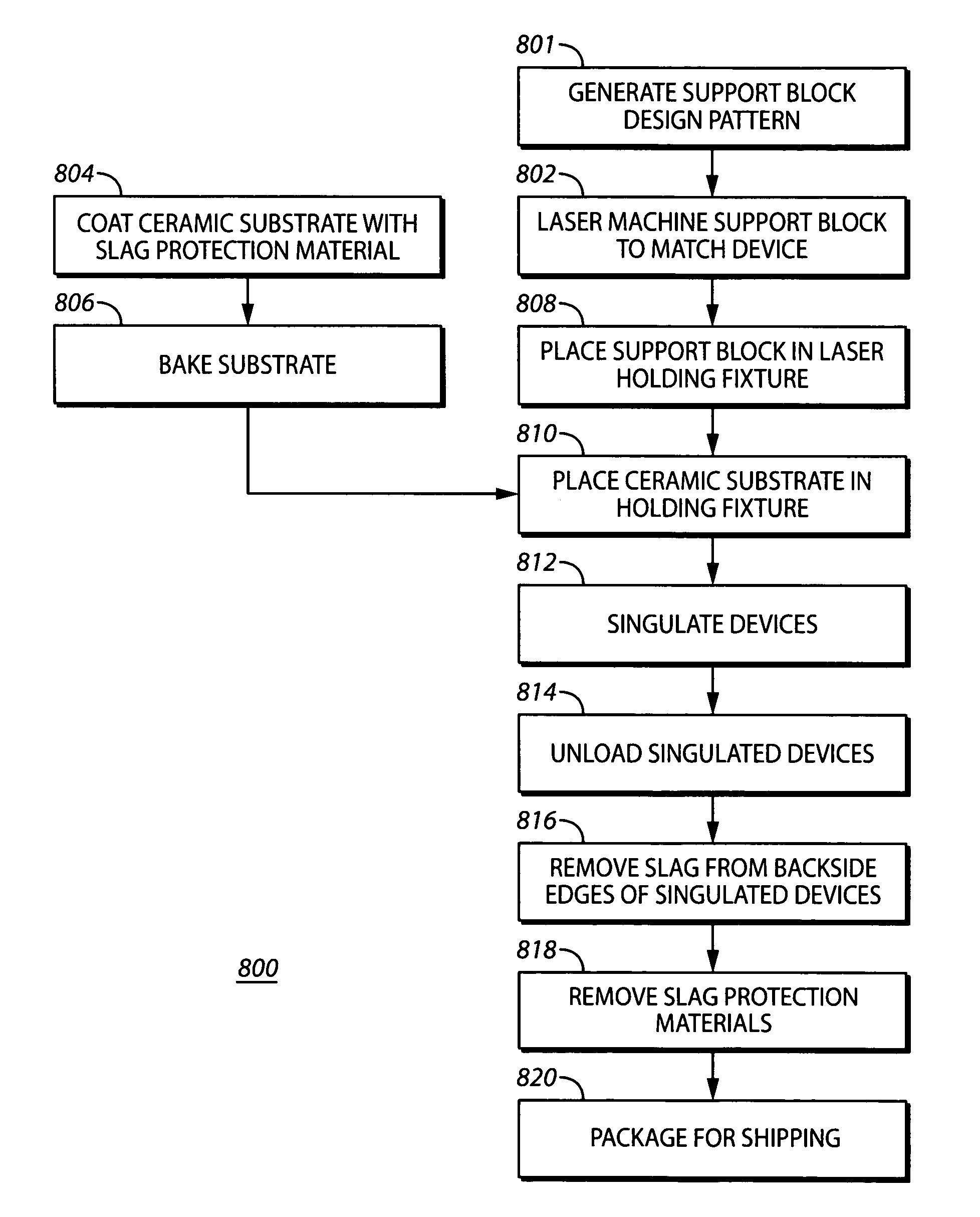

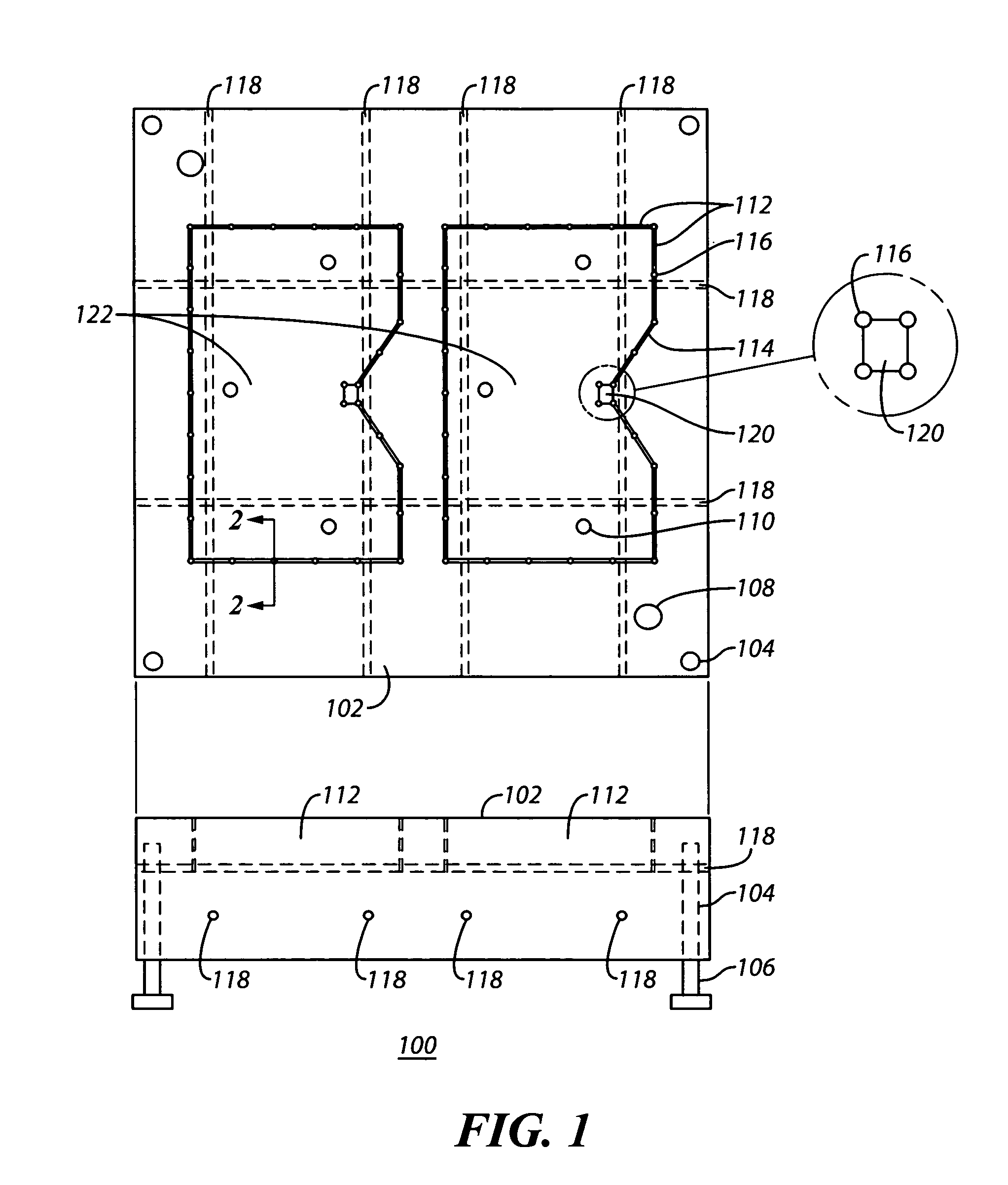

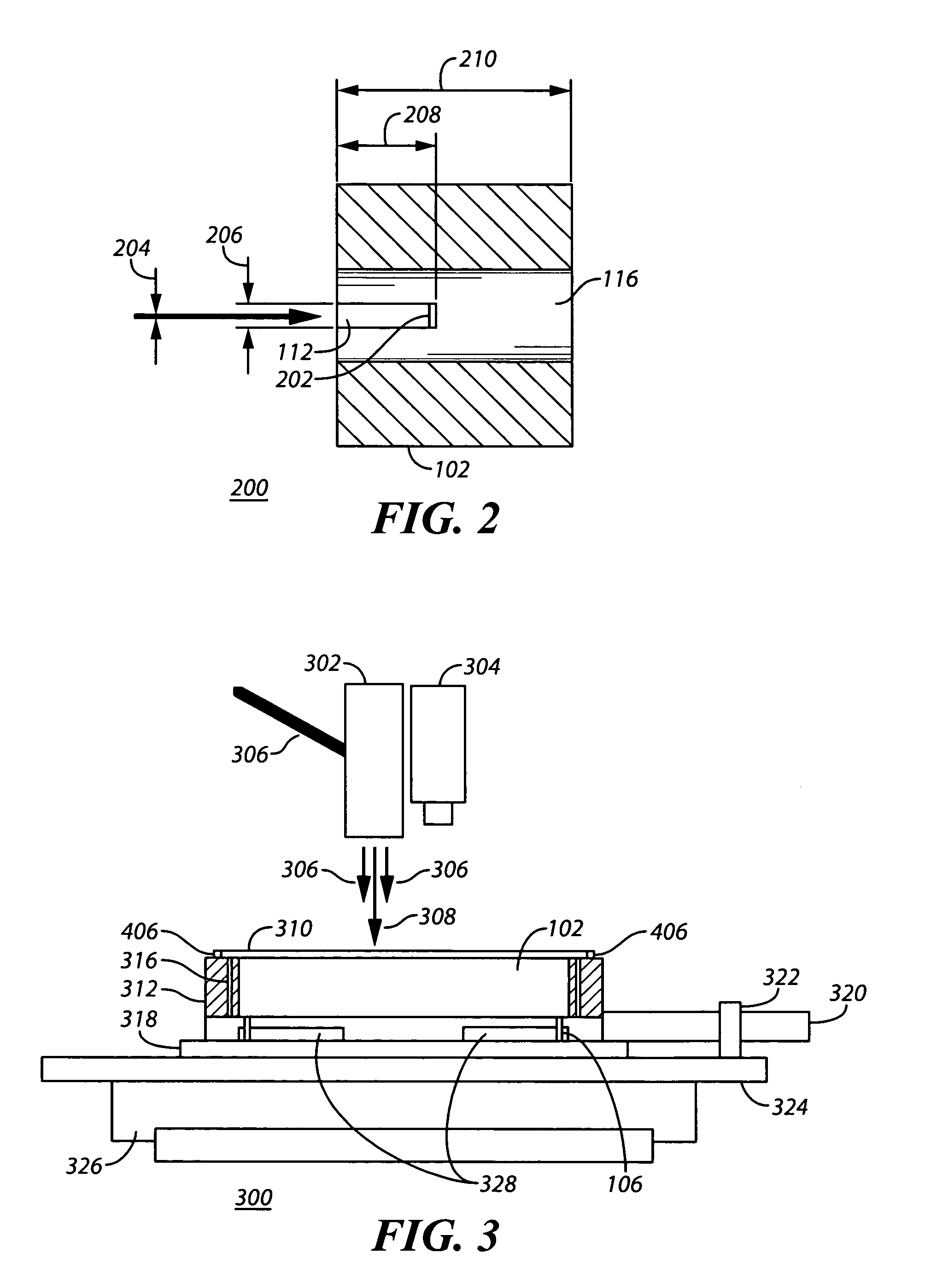

System and method for singulating a substrate

A laser cutting system includes a laser generating a laser cutting beam for singulating an electronic device from a substrate. A support block is laser machined to include a channel corresponding to an outline of the electronic device to be singulated. Also laser machined within the channel are slag removal vacuum ports. The slag removal vacuum ports are used to remove slag and hold small cutout during singulation. The support block also includes device vacuum ports for holding the electronic device in position after being singulated.

Owner:AGILENT TECH INC

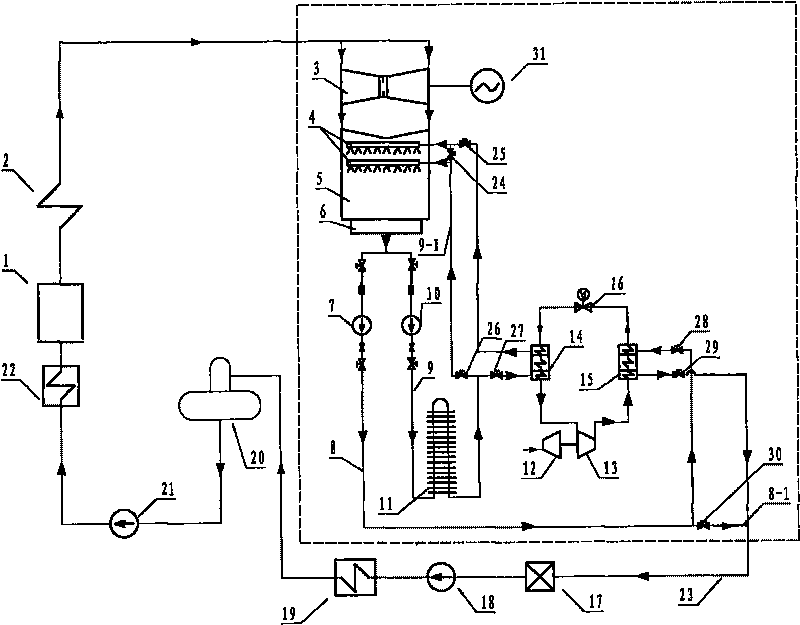

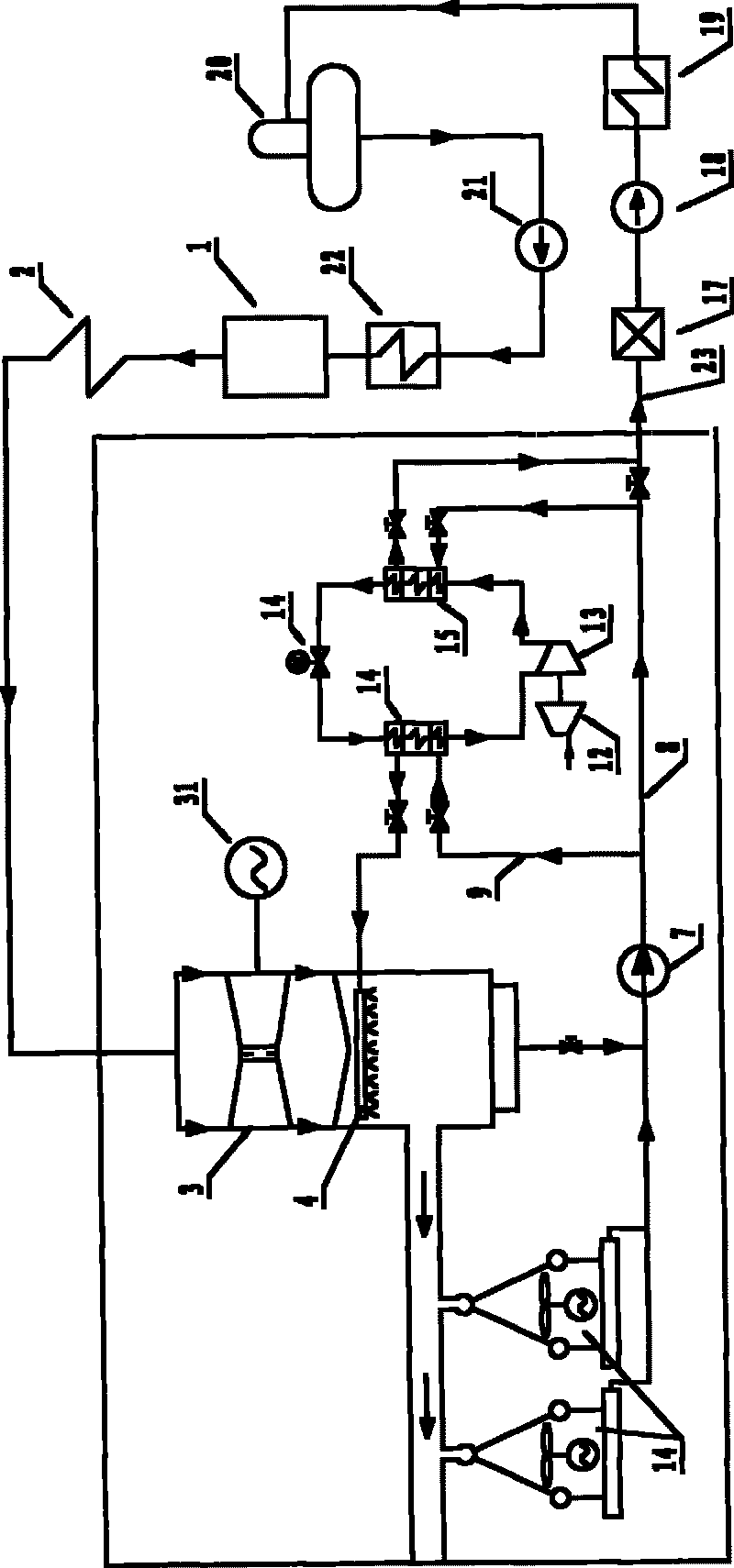

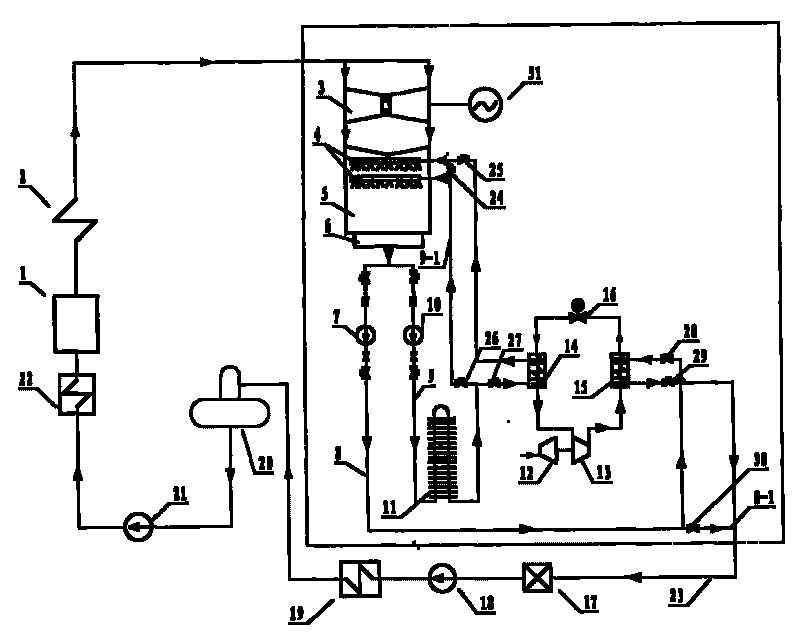

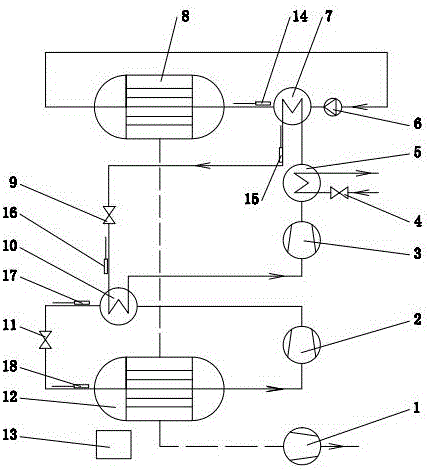

Steam exhausting cooling method and device of condensing steam turbine of auxiliary thermal power station

InactiveCN101694167AImprove economyReduce the degree of impact on the climate environmentEngine componentsSteam engine plantsRefrigeration compressorEngineering

The invention relates to steam exhausting cooling method and device of a condensing steam turbine of an auxiliary thermal power station, belonging to the technical field of power generation and solving the defects existing in the traditional cooling system of the condensing steam equipment. The technical scheme is achieved as follows: a mixed cooling mode is adopted in a process of exhausting steam of the turbine, condensed water in a hot well of a condenser is divided into two paths, one path of the condensed water sequentially enters an air-cooled heat radiator and a refrigeration equipment evaporator for cooling, and then is sprayed into the condenser by a condenser water spraying mechanism to be mixed with exhausted steam of the turbine for heat transmission, condensation heat of the exhausted steam of the turbine is absorbed, condensation equipment is kept vacuum; and the other path of the condensed water passes through a refrigeration equipment condenser, and enters a low-pressure heater after the temperature is raised so as to realize the heat transfer. The invention can flexibly adjust the refrigerating capacity of the cooling system so as to enable the condensing steam equipment to reach an appropriate vacuum and strength the economical efficiency of thermodynamic system; can reduce the climatic environmental influence degree on machine sets and strength the output stability of the device; and also can enable partial condensation heat and the transition heat of power consumption of a refrigeration compressor and the like to be recovered by the condenser for heating and water supply, thereby reducing the loss of the low-temperature end heat.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

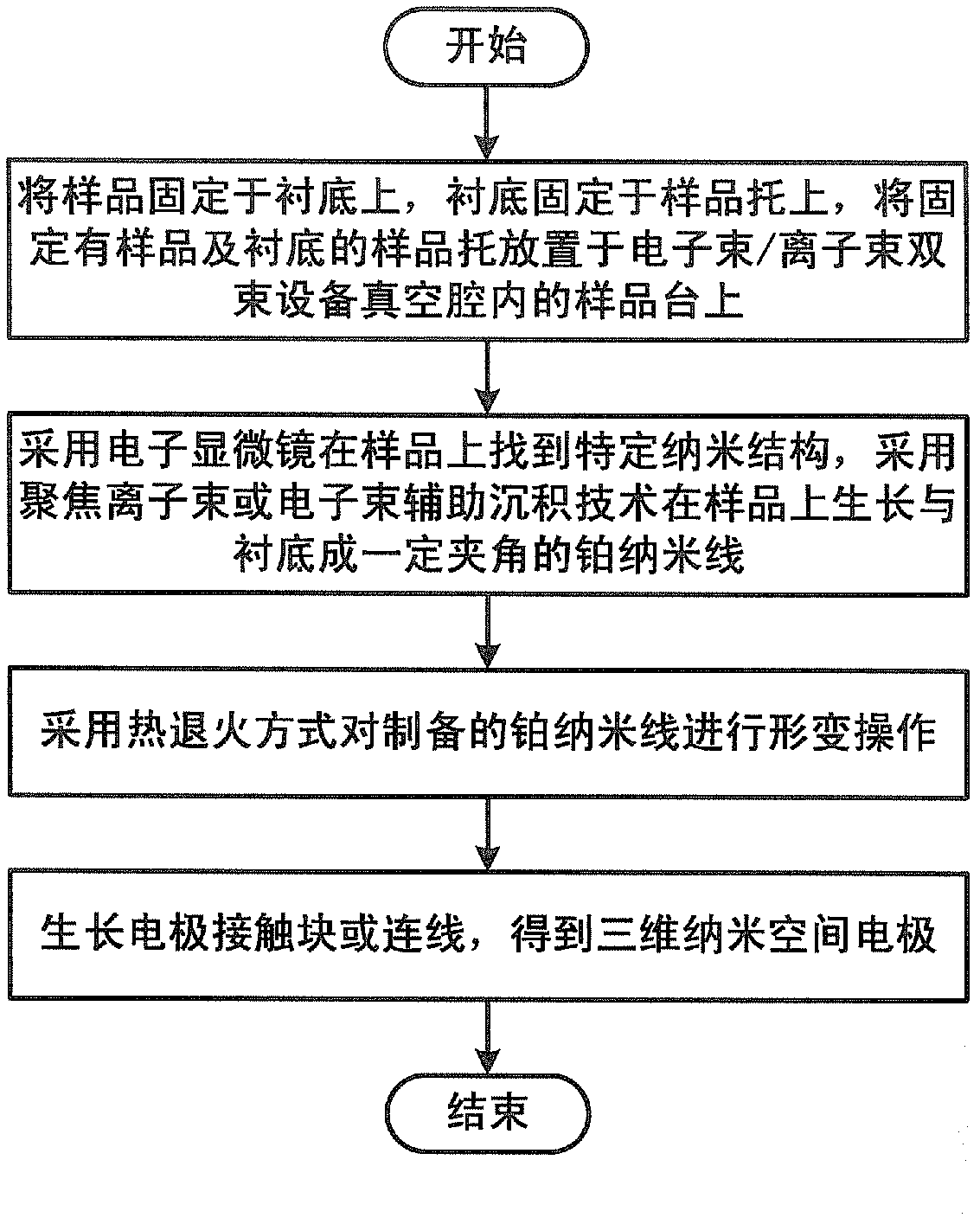

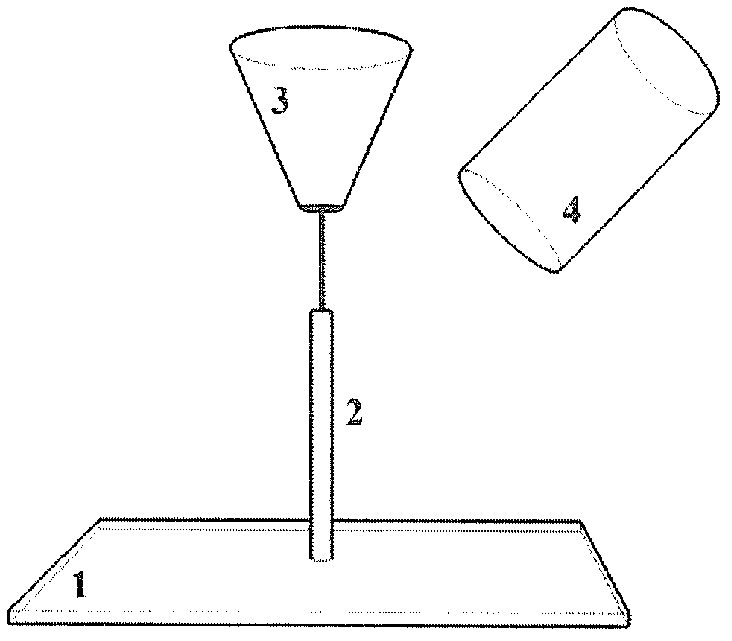

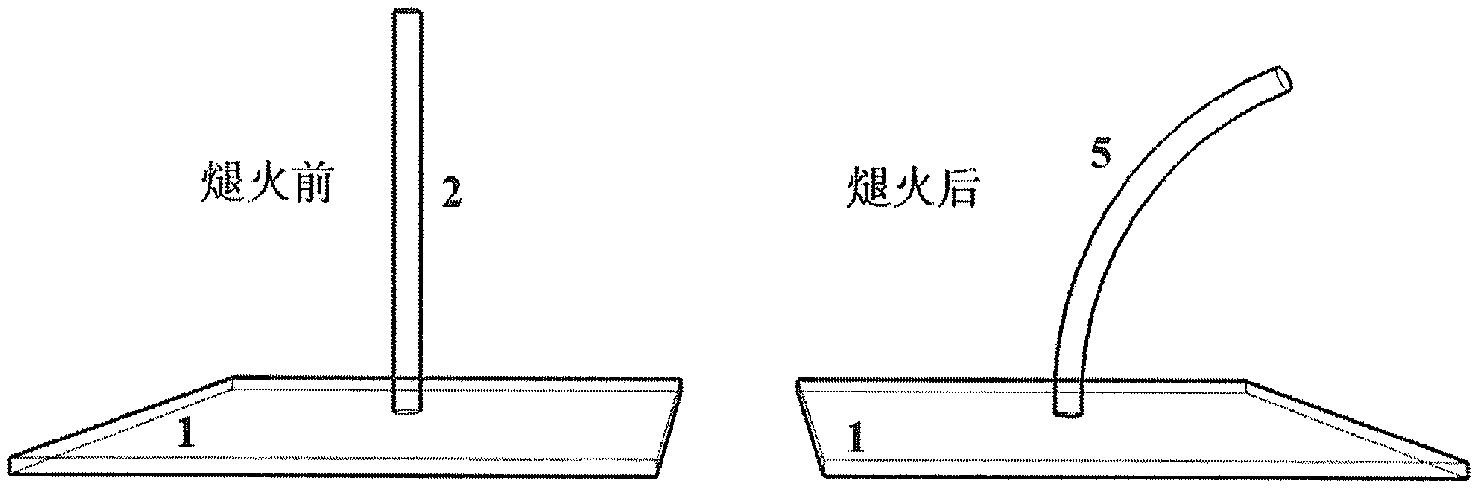

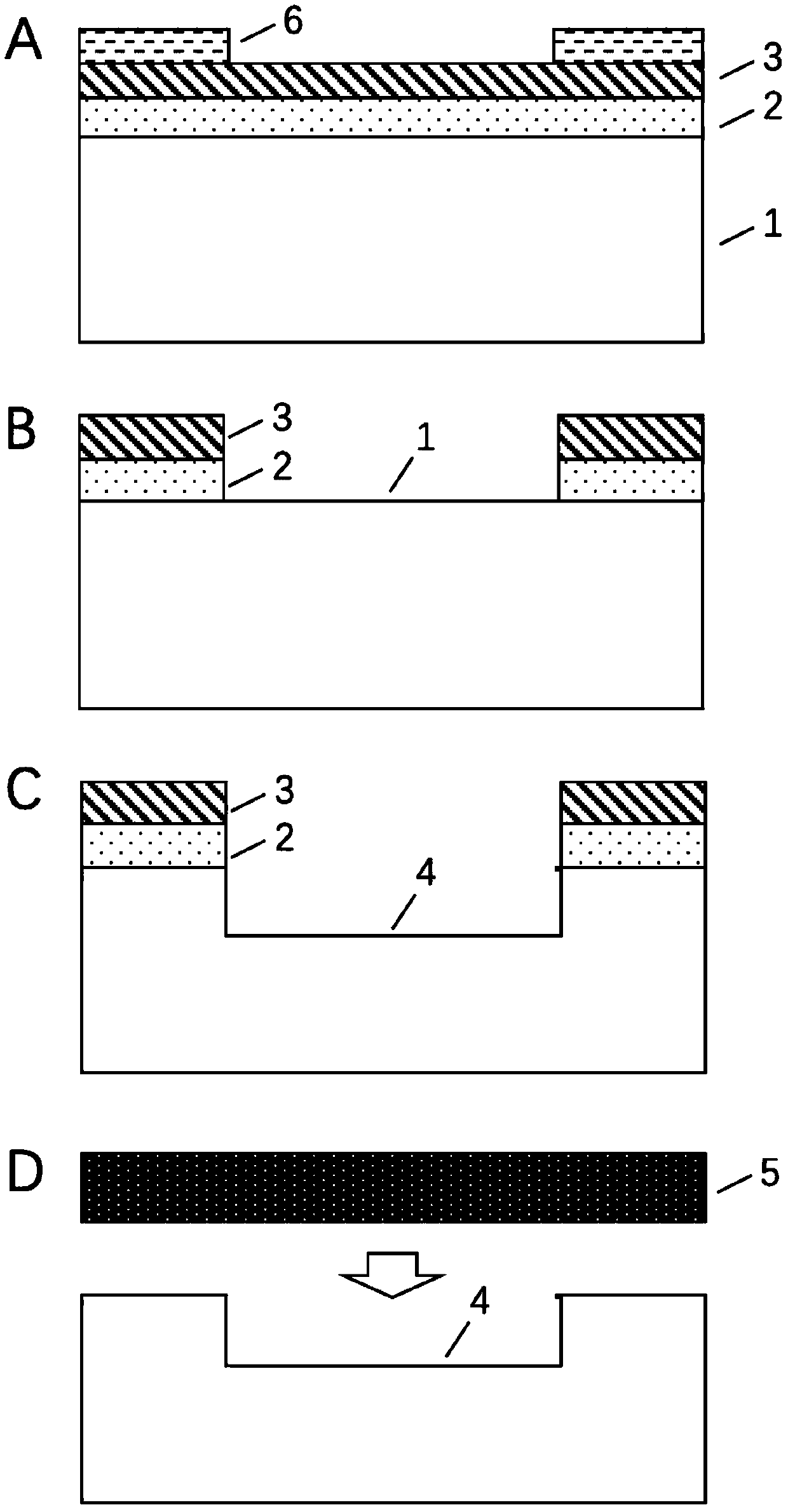

Method for preparing three-dimensional nano space electrode by adopting self-alignment forming

ActiveCN102320566AImprove controllabilityHighly repeatableNanostructure manufactureElectrode ContactNanostructure

The invention discloses a method for preparing a three-dimensional nano space electrode by adopting self-alignment forming. The method comprises the following steps of: fixing a sample on a substrate, fixing the substrate on a sample support, and placing the sample support fixed with the sample and the substrate on a sample table in a vacuum cavity of electron beam / ion beam double-beam equipment; finding a specific nano structure in the sample by adopting an electron microscope, and then growing a platinum nano wire for forming a certain included angle with the substrate on the sample by adopting a focusing ion beam / electron beam assisted deposition technology; performing deformation operation on the prepared platinum nano wire by adopting a thermal annealing mode; and growing an electrode contact block or a connecting wire, and thus obtaining the three-dimensional nano space electrode. The preparation method for preparing a micro / nano structure not in a substrate supporting plane based on the phenomenon of regular deformation of the focusing ion beam / electron beam assisted deposition thermally-annealed platinum nano wire has the characteristics of good flexibility and high controllability.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Process for producing conductive cloth

InactiveCN1408897AProcess system is stableNo dustingVacuum evaporation coatingSputtering coatingFiberMetallurgy

The conductive cloth producing process is one physical vapor deposition process. Continuous fiber fabric is made to pass through a serial technological process inside a vacuum equipment so that single or multiple sputtered metal film is formed on th fabric. The said process can producing conductive cloth with metal layer bonding to fiber fabric firmly continuously and in large scale.

Owner:长沙鑫邦工程新材料技术有限公司

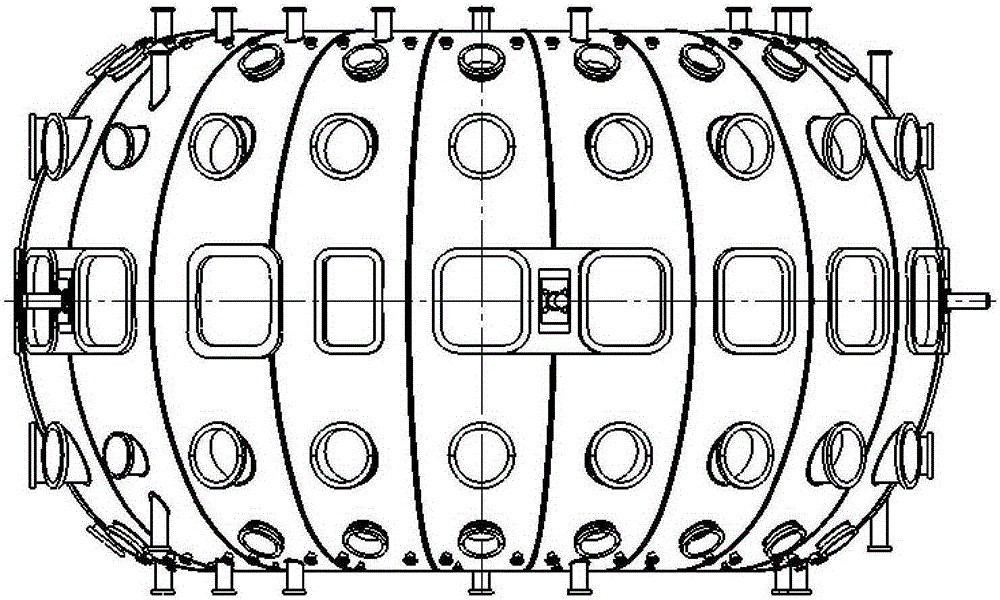

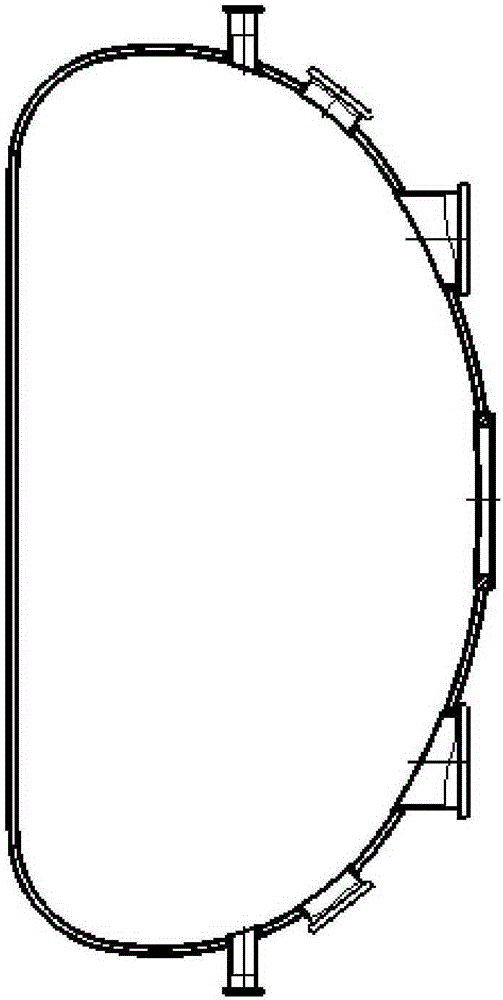

Large double-layer thin-wall D-type section vacuum chamber window assembly welding positioning device

ActiveCN105234614AControl welding deformationEnsure consistencyWelding/cutting auxillary devicesAuxillary welding devicesExperimental researchNuclear fusion

The invention belongs to the technical field of annular magnetic confinement nuclear fusion experimental research devices, and particularly relates to a tokamak device vacuum chamber window assembly welding positioning device. The tokamak device vacuum chamber window assembly welding positioning device comprises lateral plates, rib plates, connecting plates, a bottom plate and a positioning shaft, wherein the two lateral plates are welded together through the rectangular rib plates; the positions of the seven connecting plates correspond to window flanges on fan-shaped sections, the number of windows in the fan-shaped sections is smaller than seven, and the connecting plates corresponding to the positions without windows are empty; the connecting plates are provided with bolt holes, and during assembly welding, the connecting plates are connected with the corresponding 5-7 window flanges on the fan-shaped sections through bolts to position a window assembly. The bottom plate is arranged on the outer lateral plate and used for fixing the window assembly welding positioning device. The two connecting plates corresponding two opposite windows are each provided with a shaft hole, and a positioning shaft penetrates through the shaft holes to be matched with inner holes of the opposite window flanges to position the fan-shaped sections. Through the design, window welding deformation is effectively controlled, and the window assembly welding efficiency is greatly improved.

Owner:西安核设备有限公司 +1

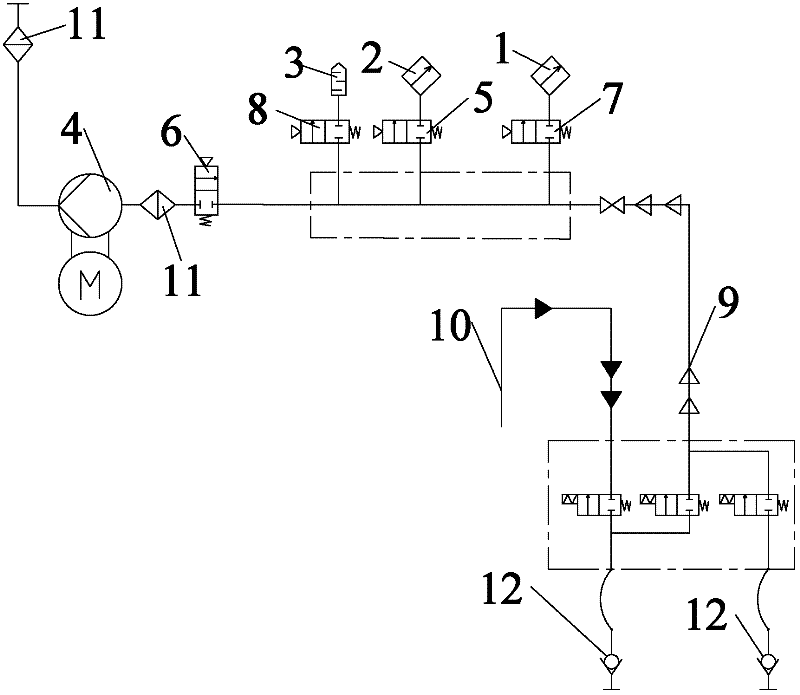

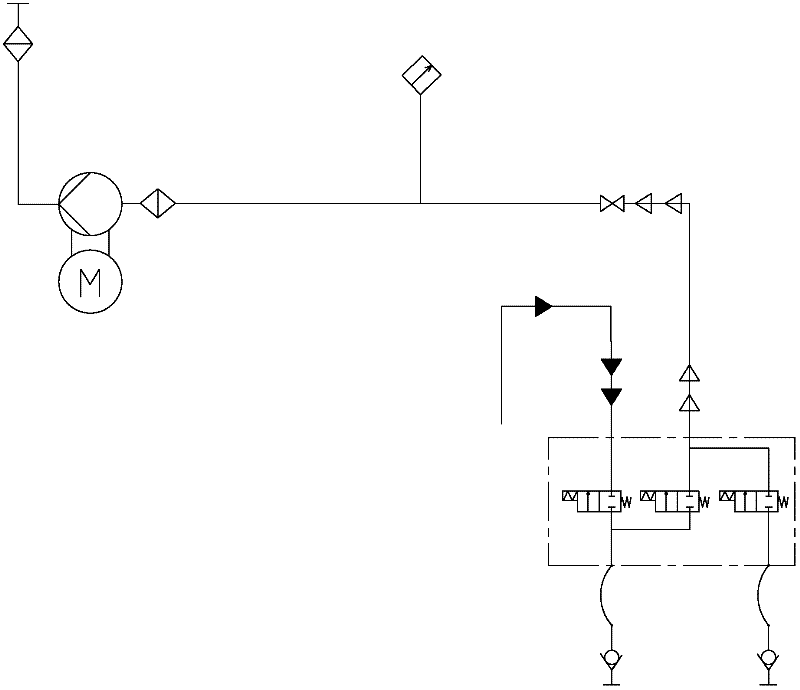

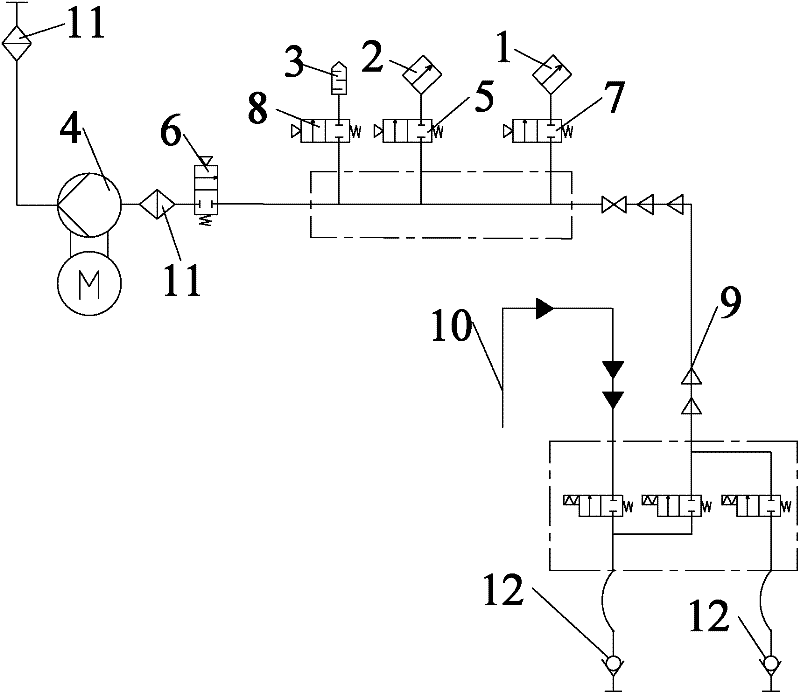

Automobile air conditioning liquid filling equipment and filling method thereof

ActiveCN102645062AAvoid damageReduce damage rateSpace heating and ventilation safety systemsSpace heating and ventilation control systemsDevices vacuumDevice failure

The invention discloses automobile air conditioning liquid filling equipment and a filling method thereof. The filling equipment comprises a filling pipeline, a vacuum detection pipeline and a vacuum sensor. The filling equipment is connected with a control system. A vacuum pump is arranged in the vacuum detection pipeline. The vacuum sensor is communicated with the vacuum detection pipeline through a branch pipeline. A first control valve is arranged in the branch pipeline of the vacuum sensor. A second control valve which is used for switching on and off the vacuum pump is arranged in the vacuum detection pipeline. A pressure sensor is arranged in the vacuum detection pipeline. By adopting the technical scheme and adding the pressure sensor and the control valve, when an operator connects the filling equipment with an automobile air conditioning liquid pipeline, firstly the vacuum sensor and the vacuum pump are disconnected from the vacuum detection pipeline, then the pressure sensor is enabled to conduct pressure detection on the air conditioning liquid pipeline, the vacuum sensor and the vacuum pump of the equipment can be prevented from being damaged because of negligence of the operator, the damage rate of the equipment is greatly reduced and the expenses in equipment breakdown maintenance are reduced.

Owner:CHERY AUTOMOBILE CO LTD

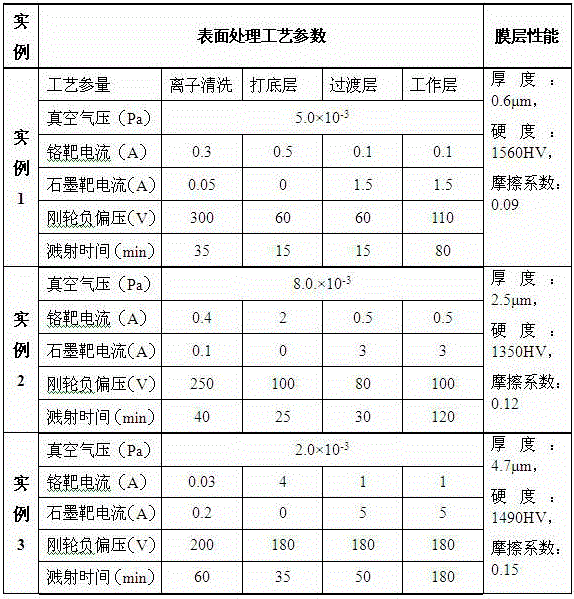

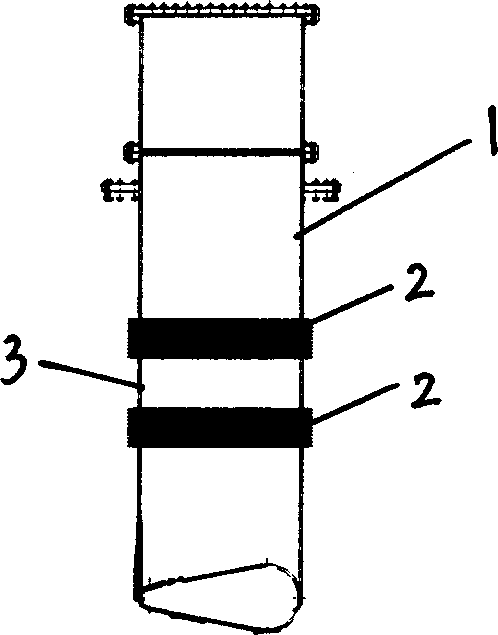

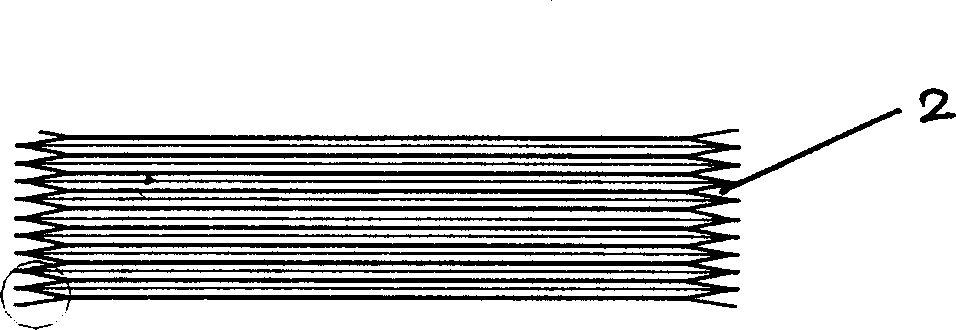

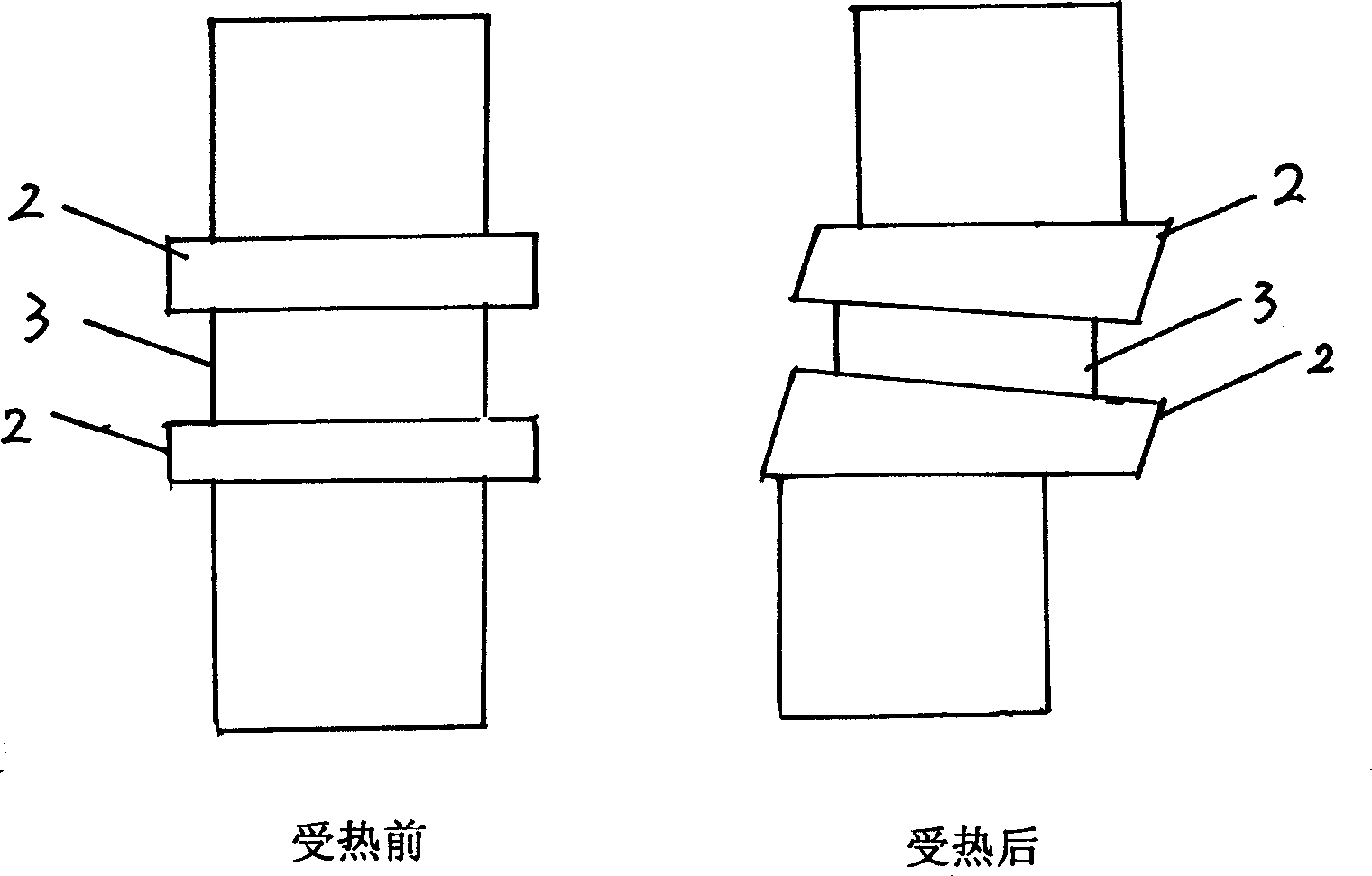

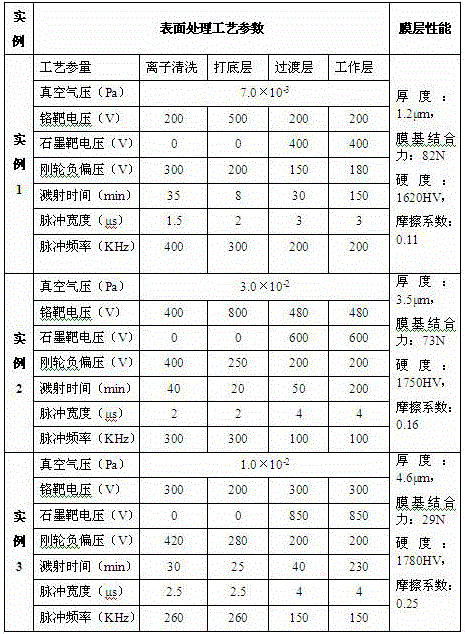

Method for ion plating of graphite-like self-lubrication film on rigid gear for harmonic reducer

InactiveCN106222616AGuaranteed uptimeReduce coefficient of frictionVacuum evaporation coatingSputtering coatingEngineeringDevices vacuum

A method for ion plating of a graphite-like self-lubrication film on a rigid gear for a harmonic reducer comprises the following implementation steps that firstly, the rigid gear is cleaned, the rigid gear is placed in a four-target micro arc ion plating device vacuum chamber after being dried, and the four-target micro arc ion plating device vacuum chamber is inflated with argon after being subjected to vacuum pumping; and after cleaning is finished through ion bombardment, film coating is conducted, a plurality of chromium targets and a plurality of graphite targets are started, and a pure-chromium bottom coating, a transition layer and a graphite-like working layer are sequentially deposited. The rigid gear treated through the method has a self-lubricating function, the rigid gear is used for the harmonic reducer, the characters of high speed, high load bearing and low friction are obtained, and accordingly the effects of reducing abrasion and prolonging the service life are achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

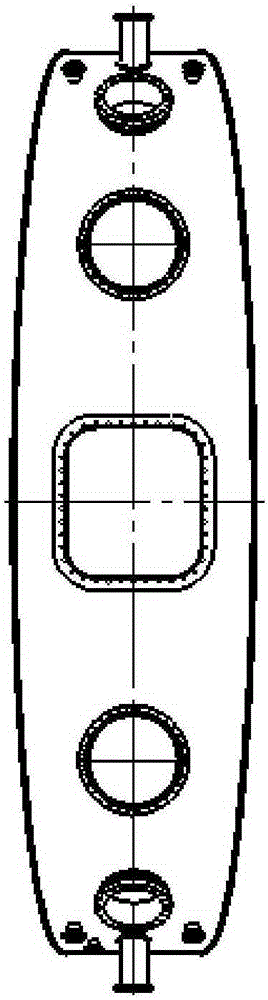

Special superconducting Tokamak nuclear fusion vacuum chamber window neck-pipe structure

InactiveCN1851830AGuaranteed to workReduce wave numberNuclear energy generationThermonuclear fusion reactorNuclear fusionSuperconducting tokamak

This invention discloses a window neck tube structure of a special superconductive Tokamak nuclear fusion device vacuum chamber, including a shell of the vacuum chamber, in which, the chamber includes a level window and a vertical window installed with neck tubes on them characterizing that said neck tubes have two sections of ripple tubes and a hard tube between the two sections of ripple tubes, thus the chamber can absorb heat distortion effectively and the neck tube keeps linearity along the axial direction so as to guarantee the normal work of some diagnosis devices.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Vacuum box type leakage inspector and inspection method

InactiveCN104713685AImprove test accuracyImprove reliabilityMeasurement of fluid loss/gain rateTester deviceEngineering

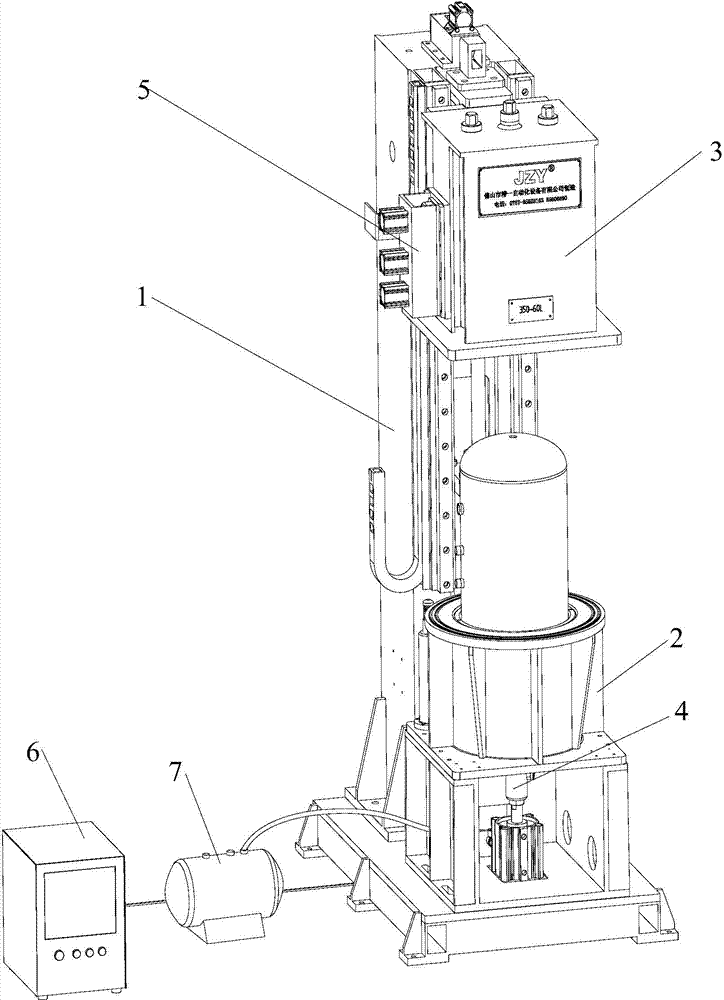

The invention discloses a vacuum box type leakage inspector. The vacuum box type leakage inspector comprises a rack, a vacuum box for containing a workpiece, a box cover moving mechanism for pressing the workpiece, an air inflow mechanism for inflating the workpiece, a plugging mechanism for plugging a water pipe opening of the workpiece, a vacuum pump connected with the vacuum box and a sealing tester connected with the vacuum pump. The air inflow mechanism is connected with the workpiece, and the workpiece is placed on a fixing die of the vacuum box. The vacuum box, the box cover moving mechanism, the air inflow mechanism and the plugging mechanism are arranged on the rack. By the adoption of the structure, the inspection result is high in accuracy and reliability. By optimizing the mechanism design of a vacuum system, the sealing performance of the vacuum system is improved, and the air leakage rate of the system is reduced; high-temperature-resistant sealing elements are selected as ancillary facilities for improving the equipment vacuum degree; the precision sealing tester is selected and used, so that the inspection result is more reliable; by the adoption of the advanced sensing technology and the precision sealing tester, the system can be automatically controlled.

Owner:HUNAN JINGYI AUTOMATION

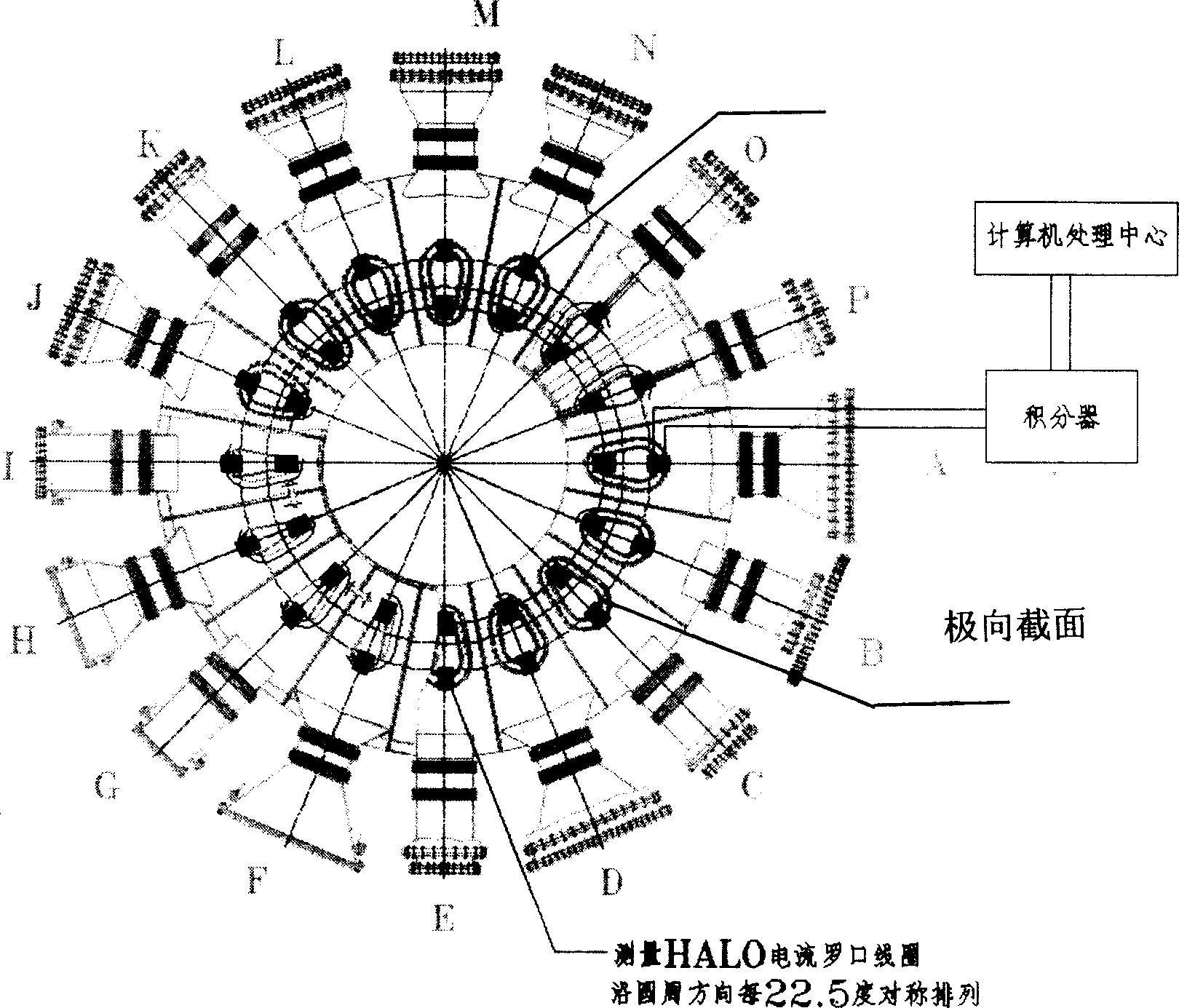

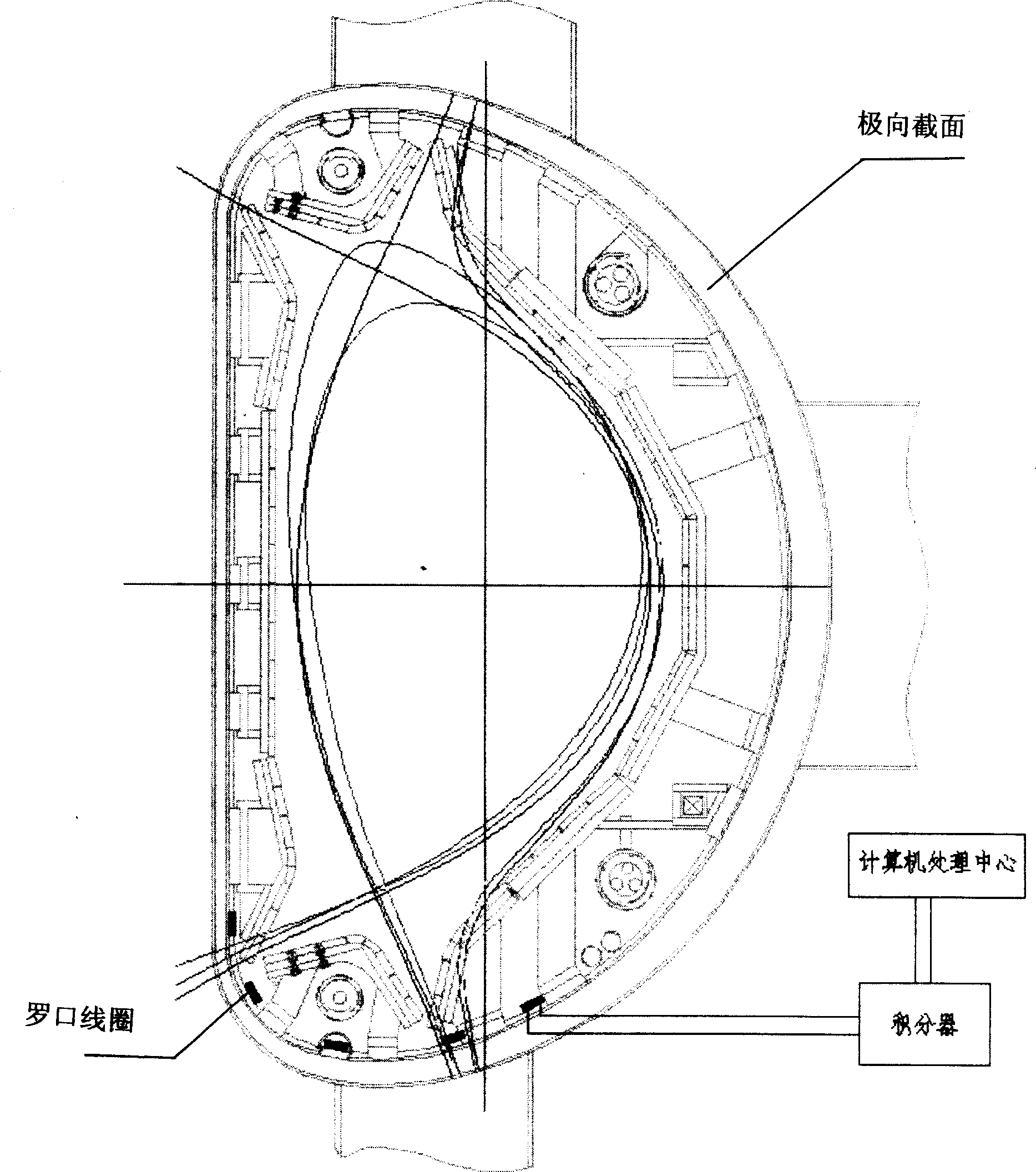

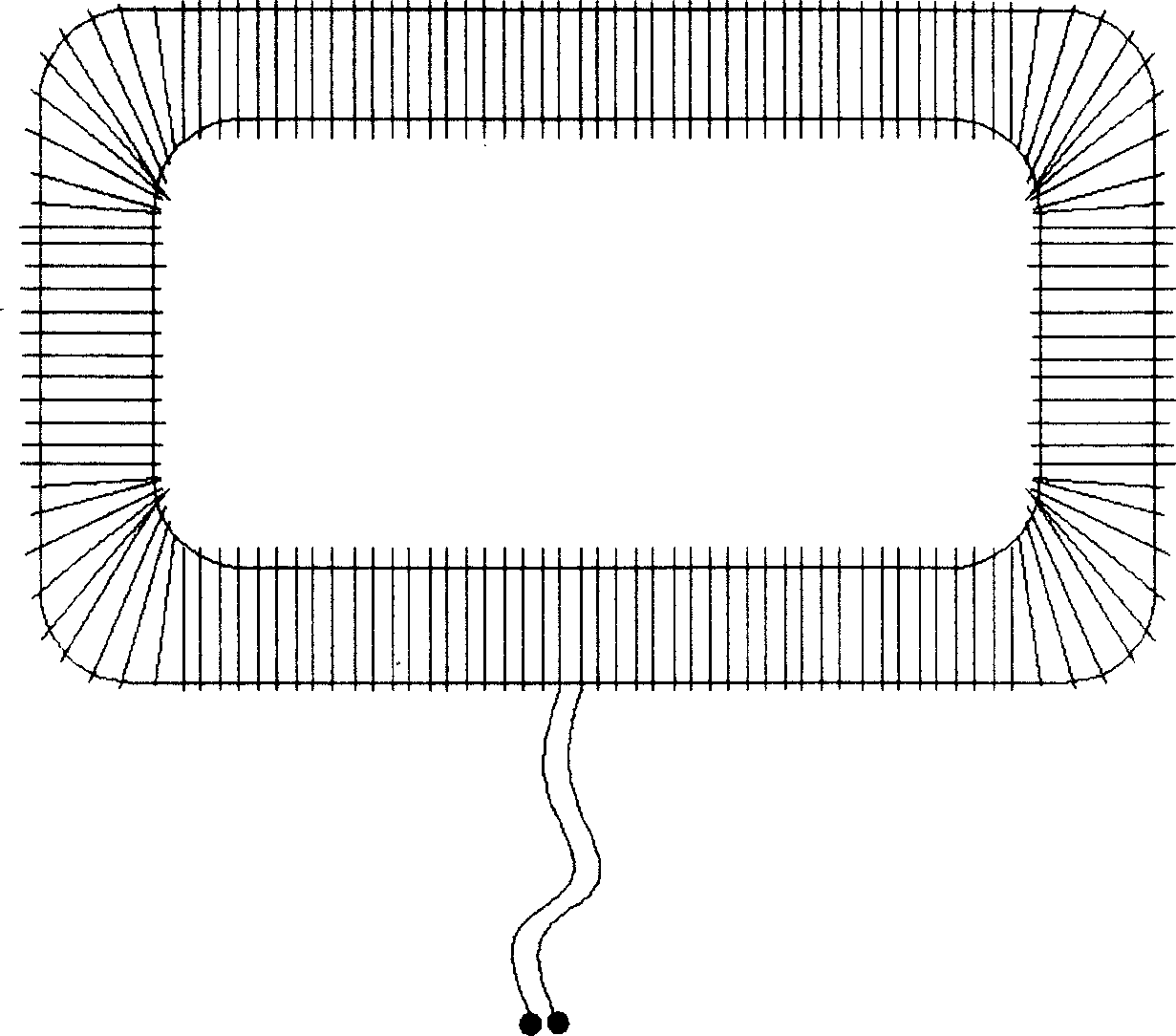

Method and device for measuring corona current in Tokamak device

InactiveCN1731914AGet sizeGain inhomogeneityRadiation/particle handlingNuclear energy generationCurrent distributionDevices vacuum

This invention discloses a method for measuring corona current in tokmak device and its device, characterized in: equipping interconnect screw coil with high frequency response in tokmak device vacuum case inwall, via inducted current of screw coil, attaining changes of vacuum inner magnetic field, based on these, via high temperature plasmas, round vertical field magnet, pole field magnet and vacuum case body in the tokmak device, testing the screw coils to attain corona current, and the non-uniformation of current distribution along ring direction.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

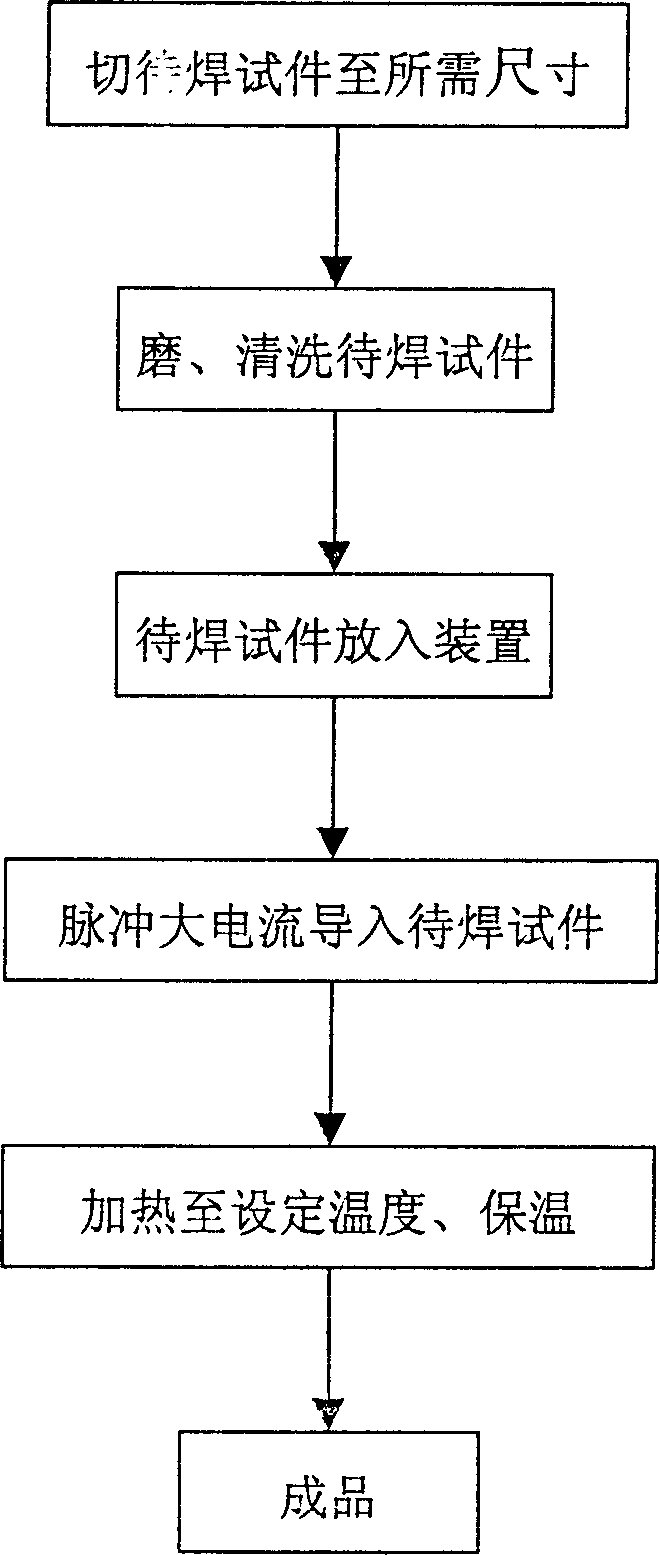

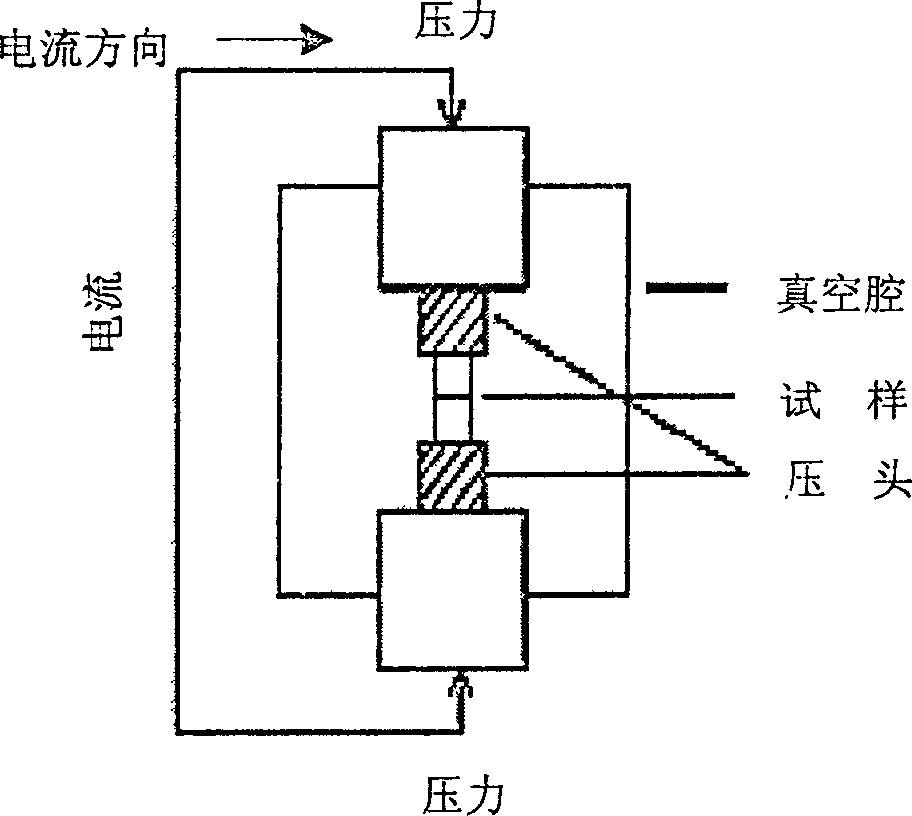

Large pulse power supply heating welding method for Ti-6Al-4V titanium alloy

InactiveCN1593833AQuality improvementShort holding timeHigh frequency current welding apparatusPower flowTi 6al 4v

The invention relates to a kind of technology to heat and weld the Ti-6Al-4V titanium alloy with big impulse current. First make above alloy into as needing size, polish it then with water sand papers of different qualities. To rubdown its surface with metallographic sand paper in order to touch the two welding surfaces more tightly. Then heat the sample being welded with big impulse current in the heating device vacuum degree of which is 4~6Pa, and send high purity Ar into the device to protect. Because the big impulse current heats the sample material into certain temperature, and maintain the temperature for a time, we can get Ti-6Ai-4v titanium of hi high mechanic property that has good quality jointing spot. The technology is simple and can cuts down the cost, saves the production time, improves production efficiency.

Owner:WUHAN UNIV OF TECH

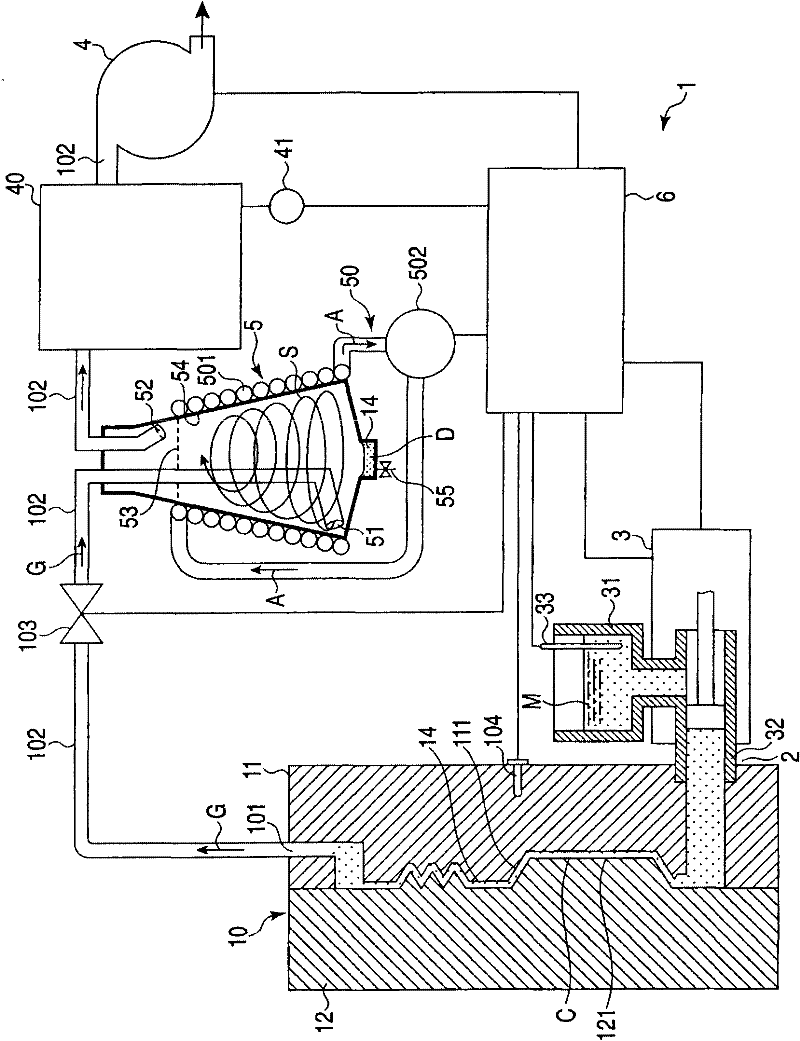

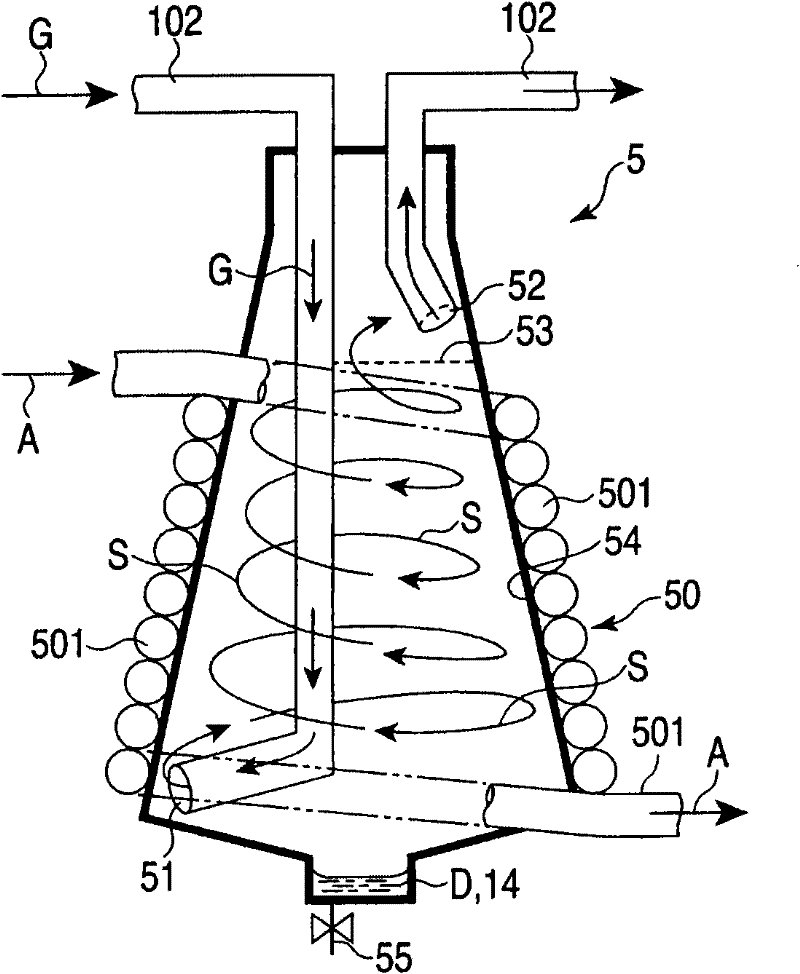

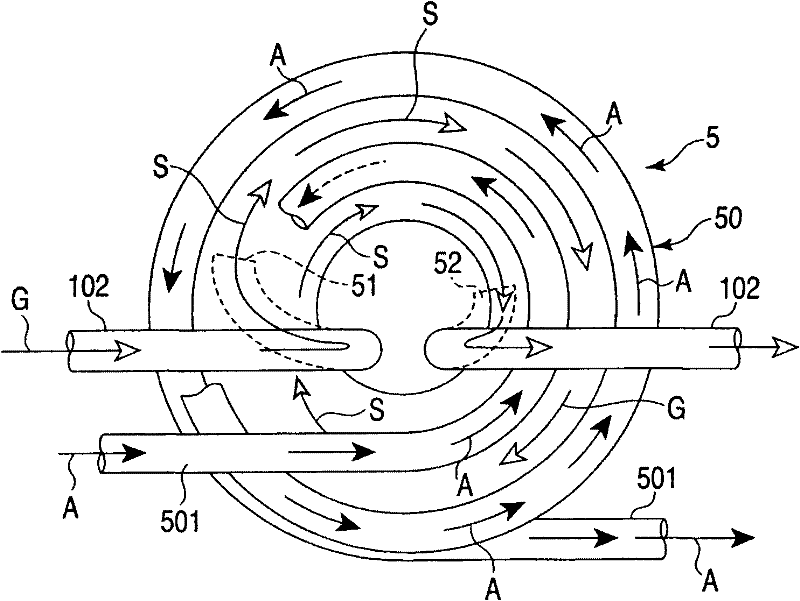

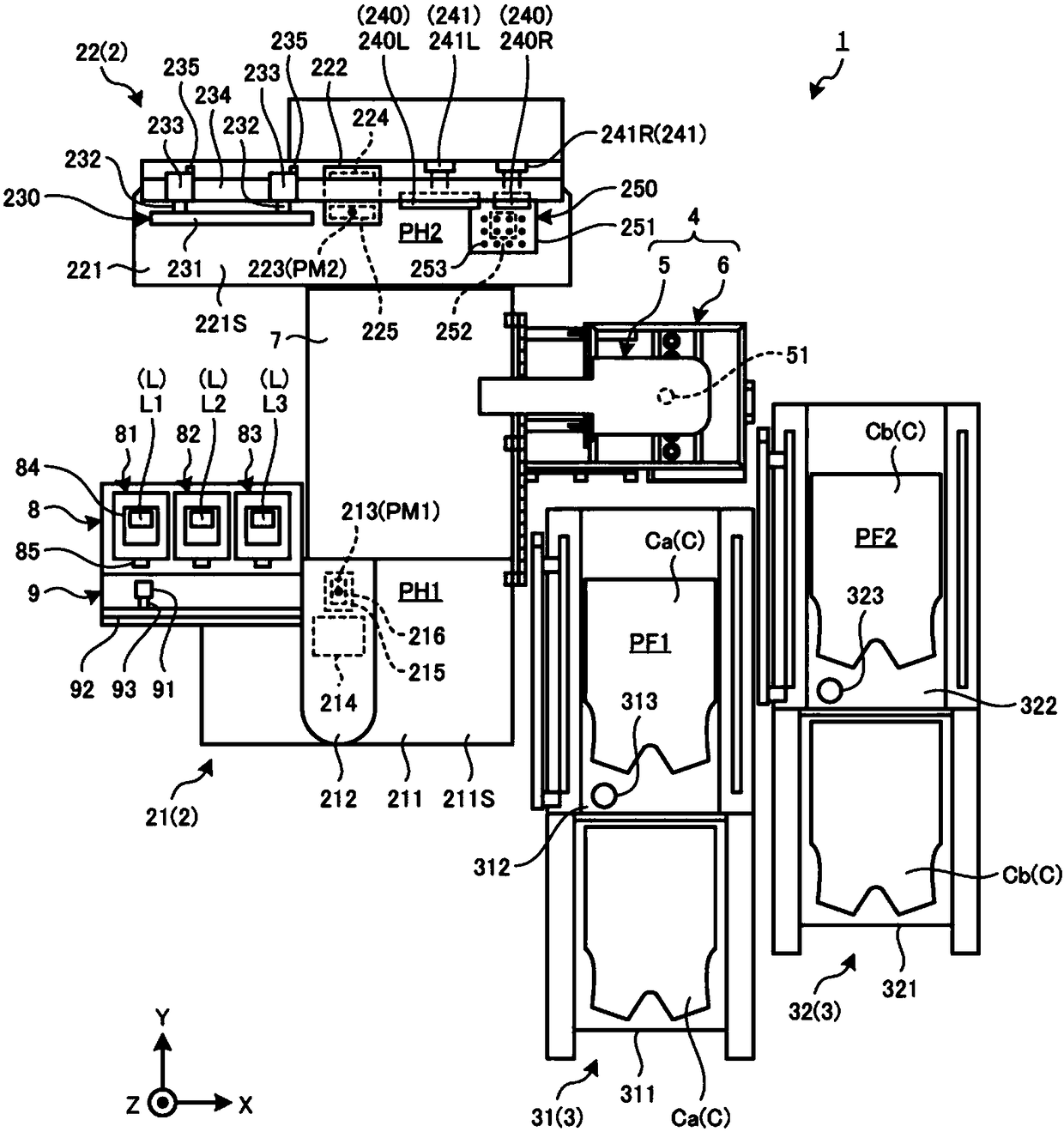

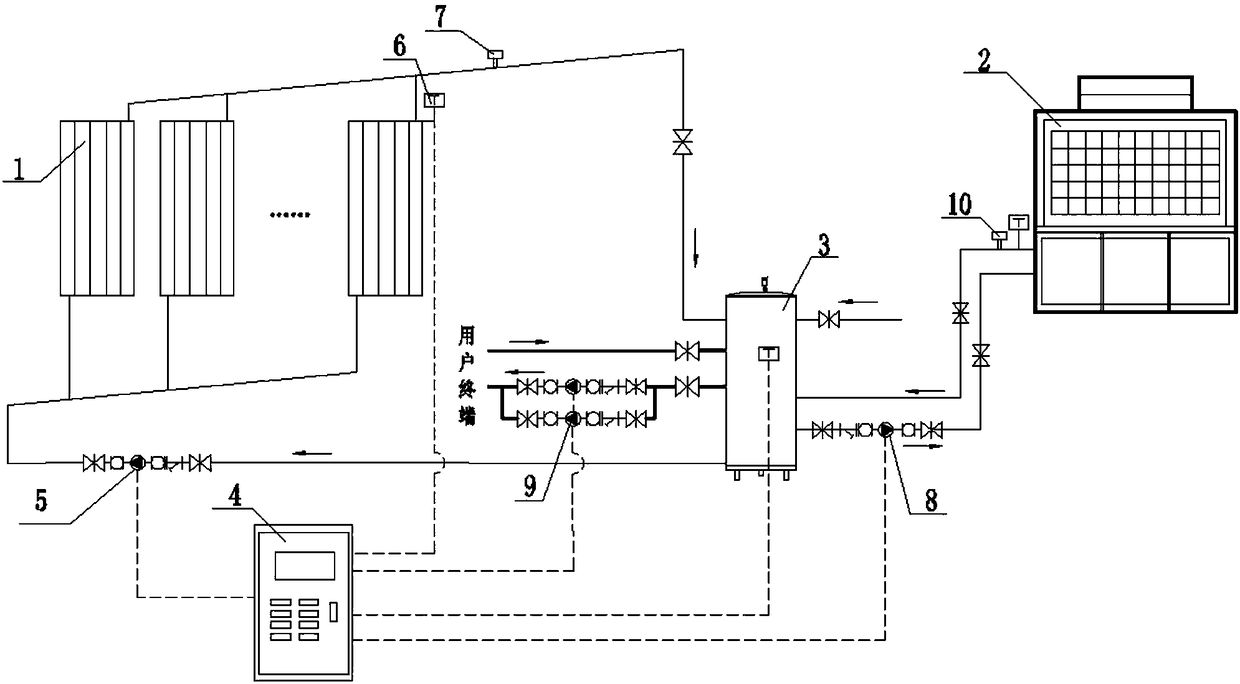

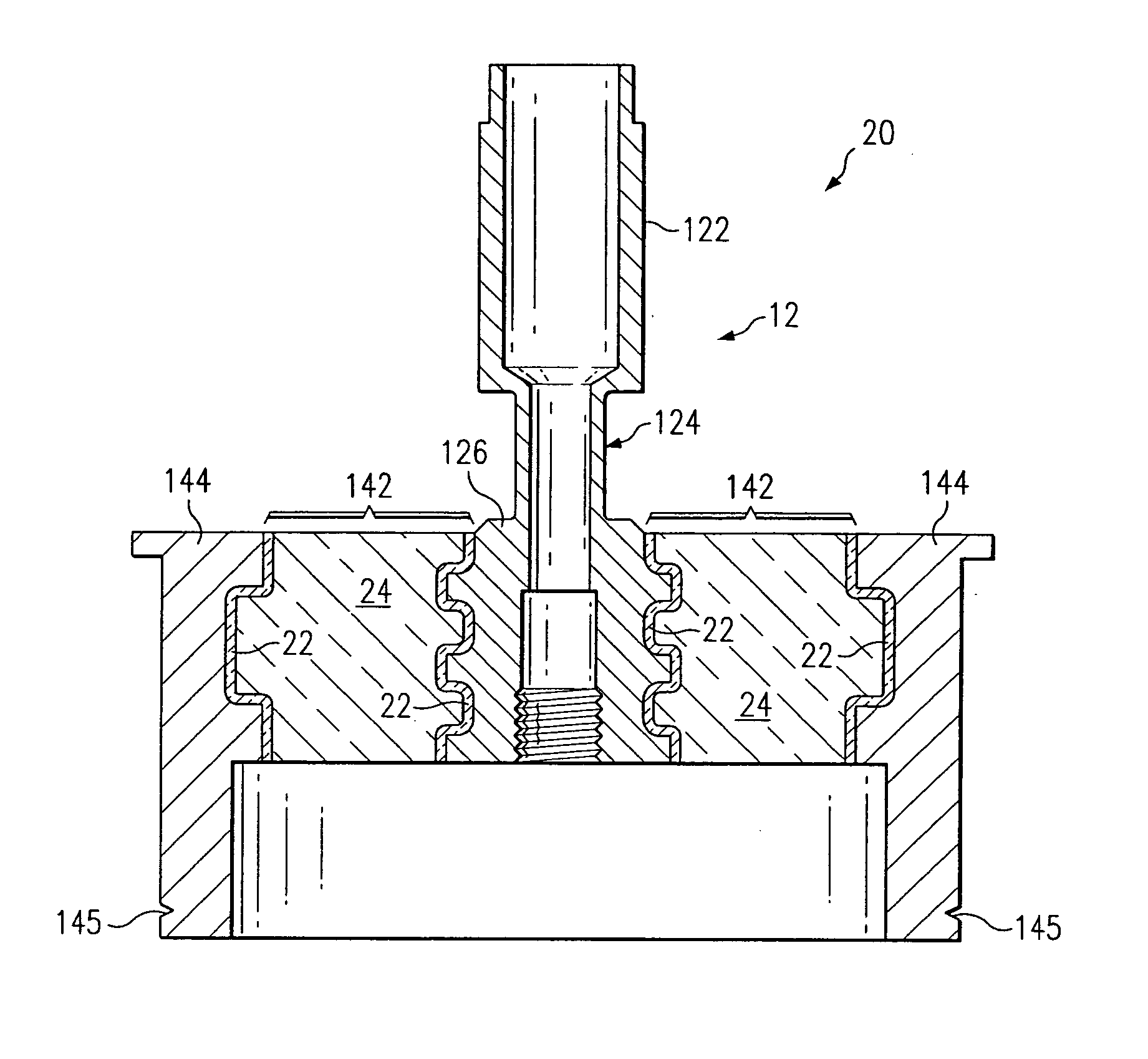

Vacuum casting device

The vacuum casting device (1) has: a mold (10), a plunger (3), a vacuum pump (4), a release agent recovery machine (5), and a cooling device (50). The mold (10) is coated with a release agent (14) on the inner surface of the cavity (C). The plunger (3) supplies the melt (M) from the melt tank (31) to the cavity (C). The vacuum pump (4) sucks out the gas (G) including the vaporized release agent (14) inside the cavity (C). The release agent recovery machine (5) is connected in the middle of the piping (102) from the mold (10) to the vacuum pump (4), and the gas (G) guided by the piping (102) is generated from the lower suction port ( 51) Spiral swirling flow (S) towards the upper exhaust port (52). The release agent recovery machine (5) utilizes the centrifugal force of the swirling flow (S) to separate the liquefied release agent (14), and discharges the residual gas from the exhaust port (52). The cooling device (50) has a cooling pipe (501) wound on the outer peripheral wall (54) of the release agent recovery machine (5), and circulates the refrigerant (A) in the cooling pipe (501), thereby The peripheral wall (54) is cooled.

Owner:TOSHIBA CLIENT SOLUTIONS CO LTD

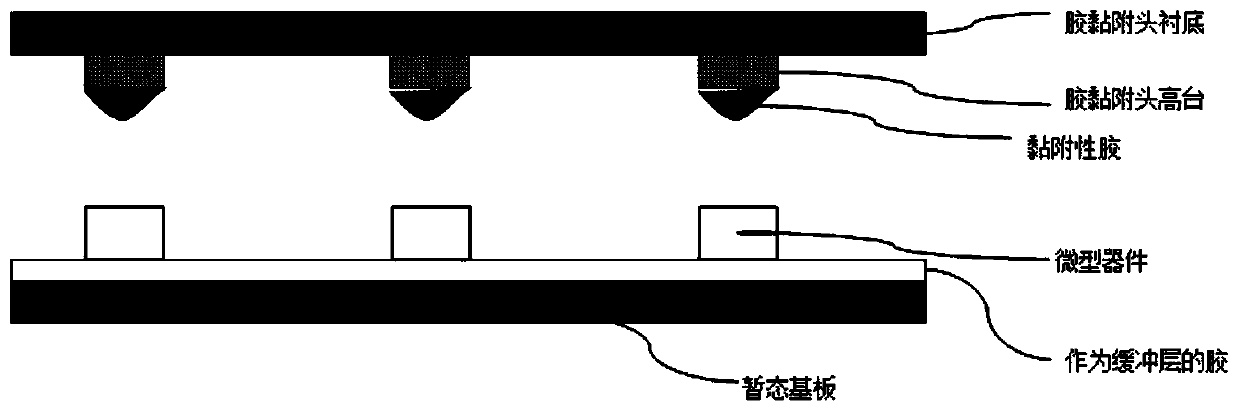

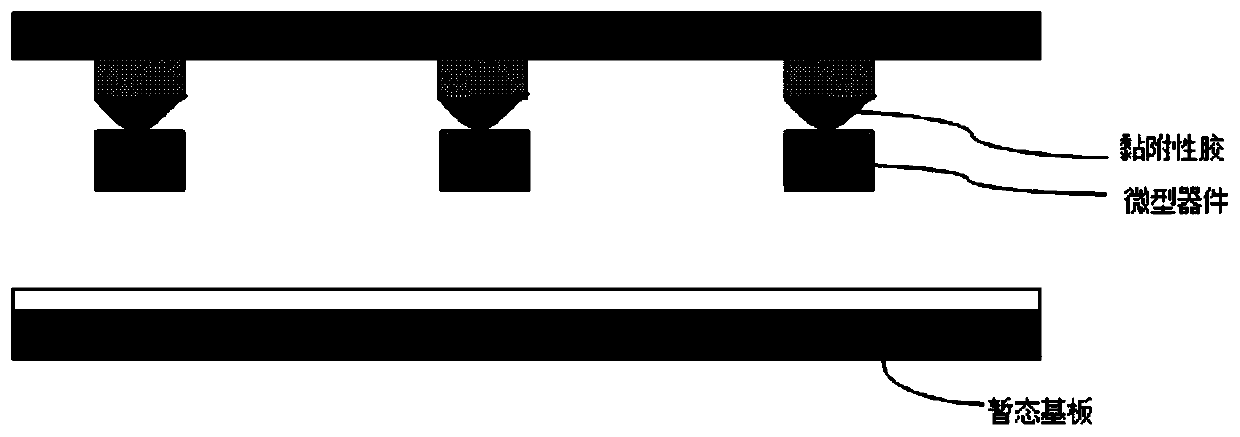

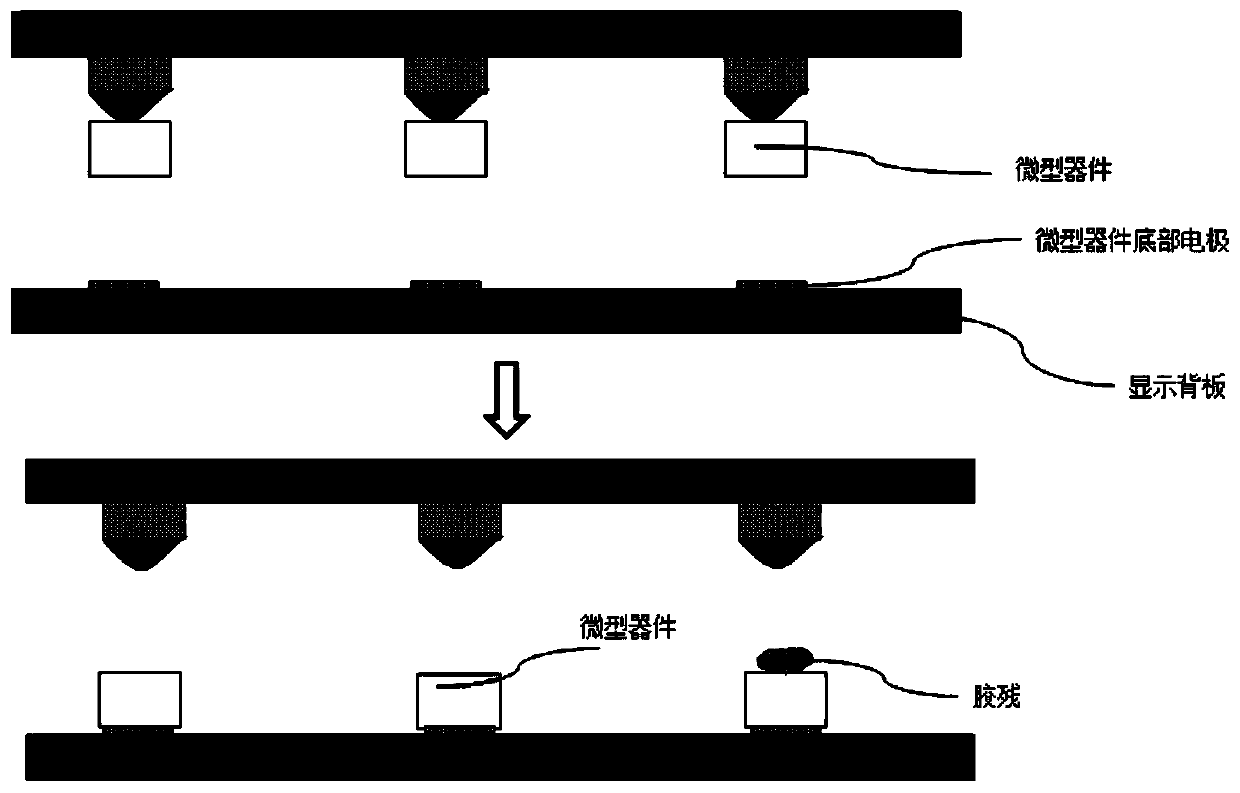

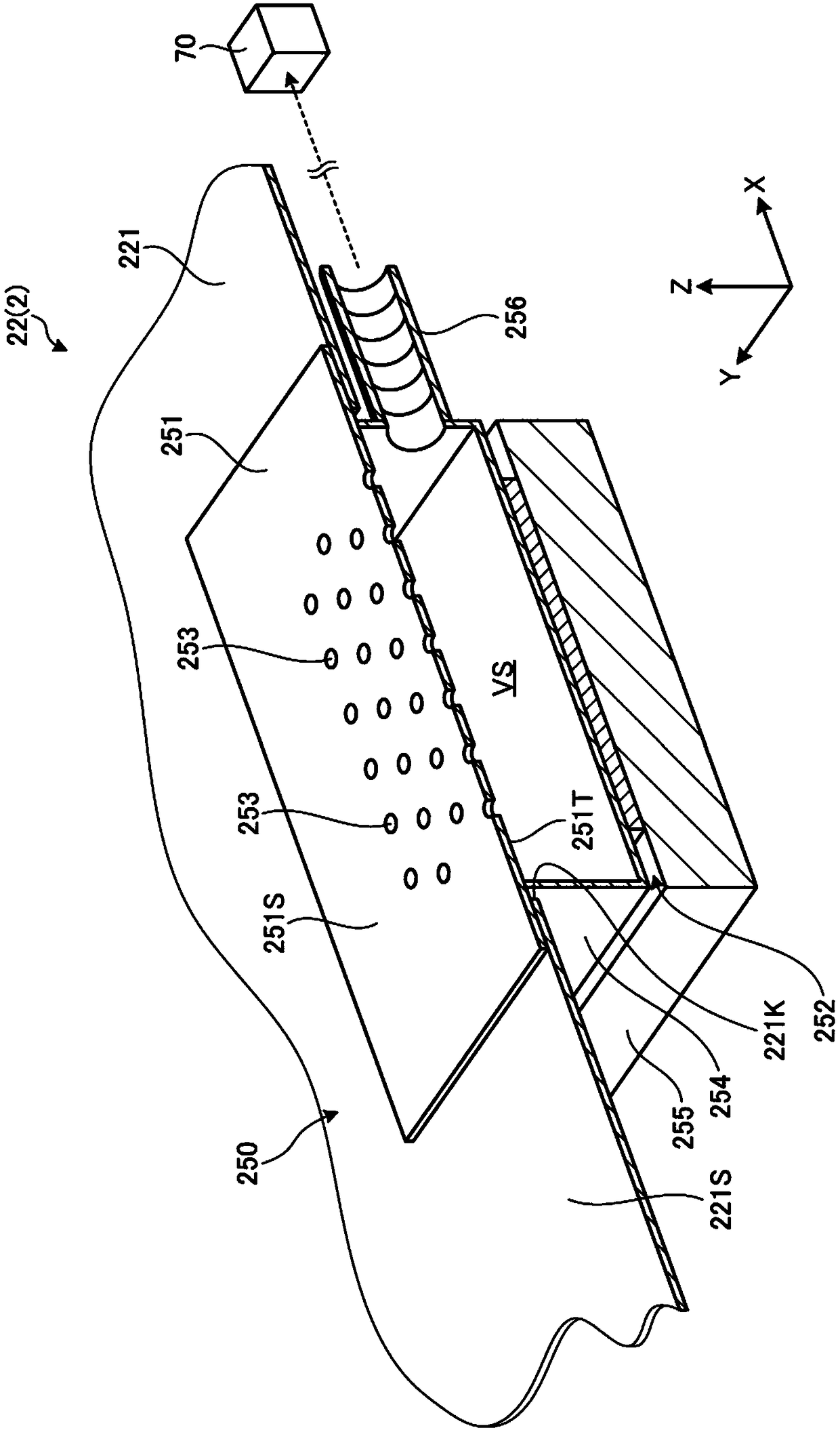

Micro device vacuum suction head and method for transferring micro device

InactiveCN110459500AIncrease profitImprove transfer efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMicro devicesEngineering

The invention provides a micro device vacuum suction head and a method for transferring a micro device and relates to the technical field of a micro light emitting diode. The micro device vacuum suction head includes a vacuum cavity with an air pump port and an air inlet, a base substrate with an array pattern, and a fall prevention ring located below the base substrate in order from top to bottom, wherein the array pattern is multiple circular stages, each circular stage is provided with a groove, and the groove has at least one micro through hole which penetrates through the base substrate and communicates with the vacuum cavity. The micro device vacuum suction head is advantaged in that the vacuum transfer head structure of a micro device is designed by using the principle of vacuum absorption so as to achieve huge transfer of micro devices, and thereby production cost is reduced.

Owner:NANJING CEC PANDA LCD TECH

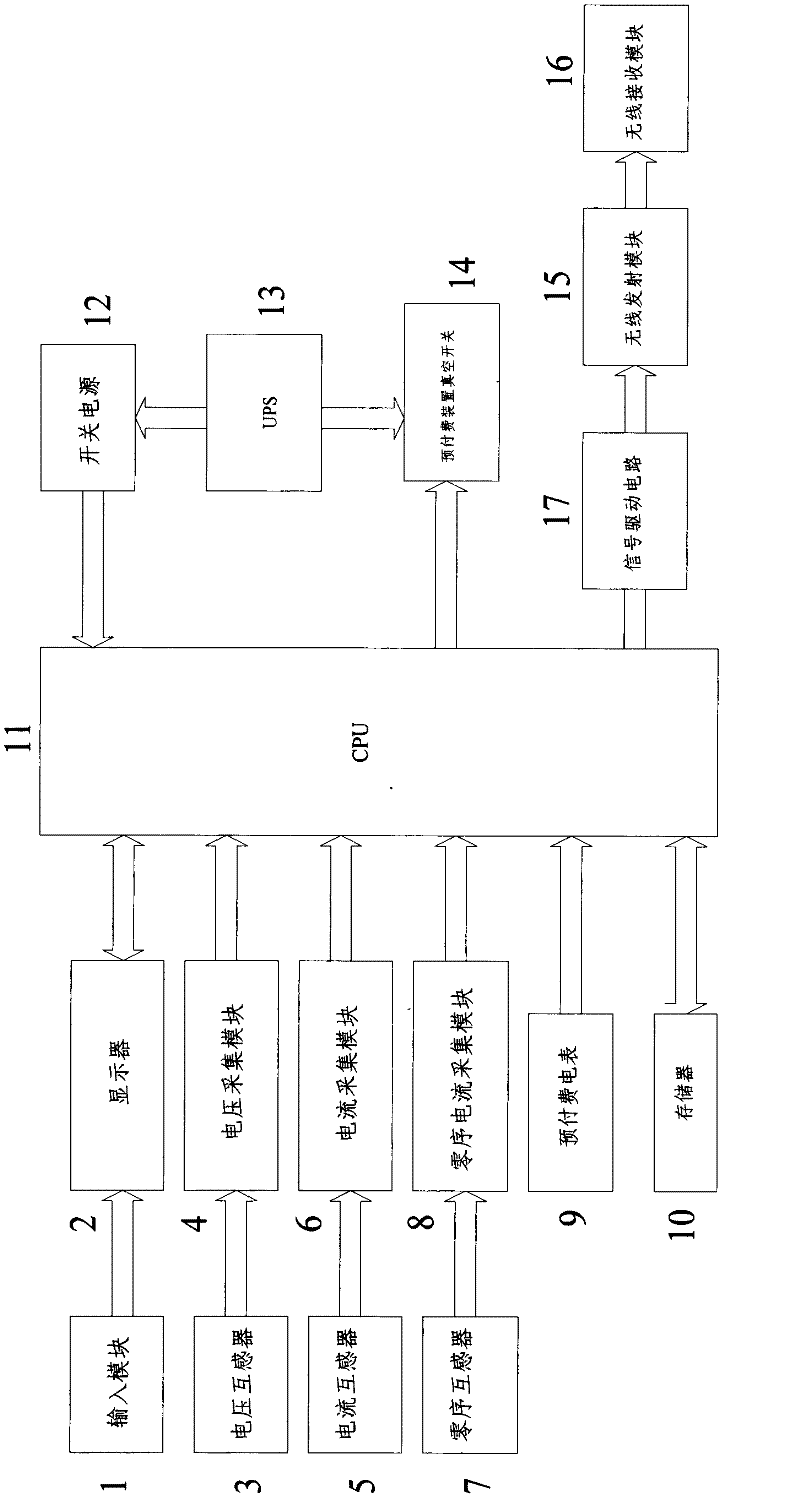

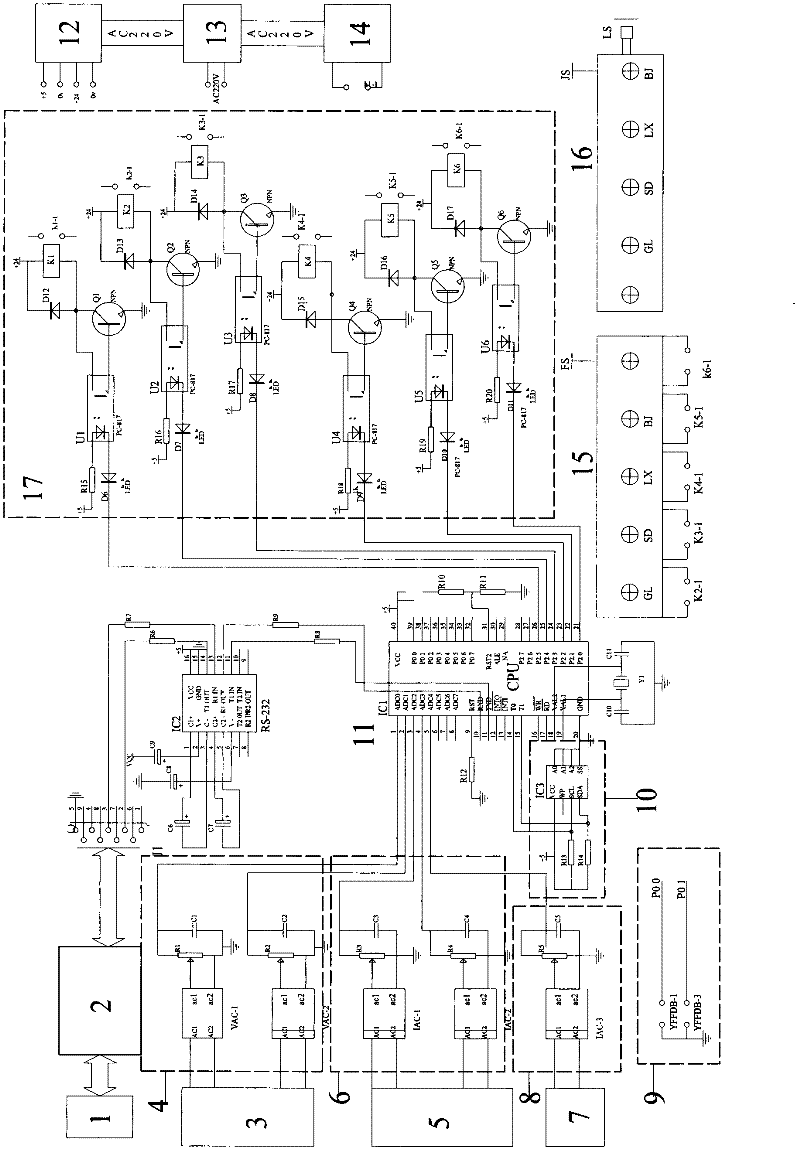

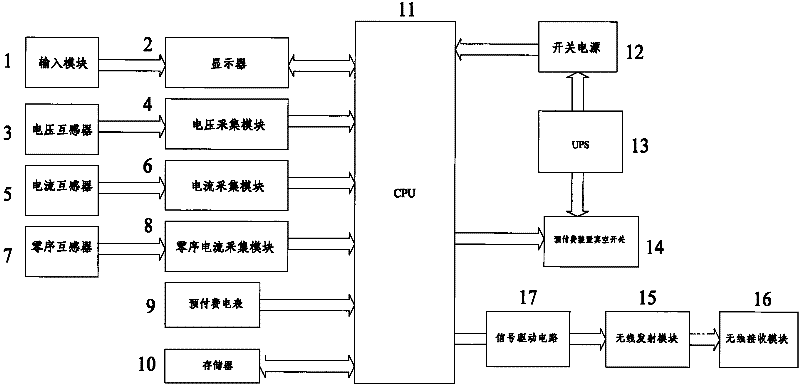

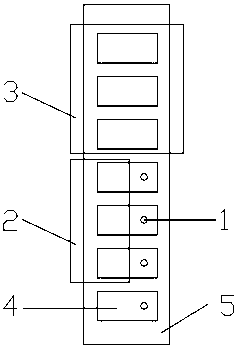

Protection unit of prepayment device

InactiveCN102394487AWith short circuit protectionWith overcurrent protection functionEmergency protective arrangements for automatic disconnectionTime integral measurementComputer moduleEngineering

The invention provides a protection unit of a prepayment device. The structure of the protection unit comprises a voltage transformer, a voltage collection module, a current transformer, a current collection module, a prepayment ammeter, a memory, a CPU (central processing unit), a switching power supply, a prepayment device vacuum switch and a signal drive circuit, wherein the voltage transformer is connected with the CPU through the voltage collection module; and the current transformer is connected with the CPU through the current collection module; and the prepayment ammeter, the memory, the switching power supply, the prepayment device vacuum switch and the signal drive circuit are respectively connected with the CPU. According to the invention, the integrated protection unit of the prepayment device is designed by using elements of the prepayment device, comprising the transformers and a circuit breaker and the like, and has the functions of short-circuit protection, overcurrent protection, zero sequence overcurrent protection, wireless communications and the like, so that the prepayment device has protection function. In addition, by using the protection unit of the prepayment device provided by the invention, while the investment of prepayment clients is reduced, the function of protecting the equipment of the clients can be realized, and the reliability of power supply is also improved at the same time.

Owner:张敬敏 +4

Method for regulating and controlling F-P optical fiber sensor sensitivity through intracavity gas pressure

InactiveCN110031127AHigh sensitivityRaise awarenessThermometers using physical/chemical changesOptical cavityDevices vacuum

The invention discloses a method for regulating and controlling F-P optical fiber sensor sensitivity through intracavity gas pressure. The method comprises the following steps: regulating the pressurein a bonding equipment vacuum chamber by utilizing the anodic bonding process of a silicon wafer and borosilicate glass, wherein the vacuum chamber pressure is 0.01MPz to 0.1MPa; manufacturing a sample with a sealing cavity between the silicon wafer and the borosilicate glass after the bonding, wherein the pressure in the sealing cavity is 0.01MPa to 0.1MPa; and finally obtaining a F-P optical fiber temperature sensor with the pressure in the optical cavity as 0.01MPa to 0.1MPa. Through the method disclosed by the invention, the sensor with different temperature testing sensitivities can be obtained, the sensitivity of the temperature testing can be regulated and controlled, so that a single sensor can satisfy different testing demands in an actual application.

Owner:SHANDONG UNIV

Cloth supply device

The present invention provides a cloth supply device, capable of smoothly conveying cloth to a cloth conveying device. The cloth supply device includes a plate member and a support device, wherein theplate member has an upper surface that sets the cloth and a lower surface that faces the opposite direction of the upper surface, and holes penetrating the upper surface and the lower surface; the support device can support the plate member at a position opposite to a suction surface of the cloth conveying device; and the cloth conveying device vacuum-holds the cloth and conveys the cloth to a sewing machine.

Owner:JUKI CORP

Micro arc ion plating surface treatment method for flexible gear for harmonic reducer

InactiveCN106119775AHigh hardnessImprove bindingVacuum evaporation coatingSputtering coatingSputter cleaningDevices vacuum

The invention discloses a micro arc ion plating surface treatment method for a flexible gear for a harmonic reducer. The method comprises the following implementation steps that firstly, the cleaned and dried flexible gear is placed into a four-target micro arc ion plating device vacuum chamber; and after vacuum pumping is conducted, the four-target micro arc ion plating device vacuum chamber is inflated with argon, after surface impurities are removed through ion sputter cleaning, micro arc ion plating is conducted, certain electrical parameters are applied to a chromium target, a graphite target and the flexible gear, a pure chromium bottoming layer, a transition layer and an amorphous carbon work layer are sequentially deposited, and the vacuum chamber air pressure and film plating time are controlled. By means of the method, the reducer is endowed with the properties of high speed, high load bearing, low friction, abrasion resistance and self-lubrication, and therefore the technological content of domestic reducers is improved, and the service life of the domestic reducers is prolonged.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

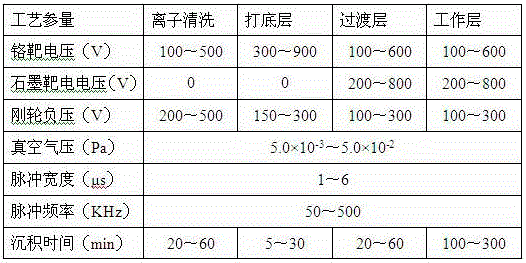

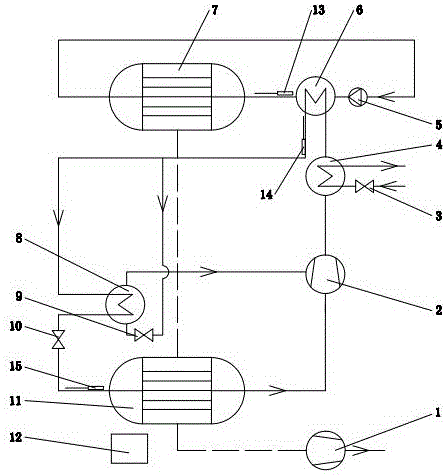

Integrated solar air source heat pump cooling and heating system

PendingCN108518782AAchieve reflowPrevent shrinkage and dentsSolar heating energyHeat pumpsWater storage tankClosed loop

The invention provides an integrated solar air source heat pump cooling and heating system and relates to the technical field of construction energy saving equipment. The integrated solar air source heat pump cooling and heating system comprises a solar energy system, an air source heat pump cooling and heating device, a water storage tank, a control cabinet, a solar vacuum breaker valve, a cooling and heating device vacuum breaker valve and the like. The gradient of preset positions of water channel pipes is 10-15 degrees. The water channel pipes are provided with the solar vacuum breaker valve and the cooling and heating device vacuum breaker valve correspondingly. The solar energy system, the air source heat pump cooling and heating device and the water storage tank form a closed loop through the water channel pipes. According to the integrated solar air source heat pump cooling and heating system provided by the embodiment of the invention, an antifreezing liquid circulation systemdoes not need to be arranged, a heat exchange device does not need to be mounted, and heat tapes do not need to be wound on the system pipes. The cooling and heating system provided by the inventioncan meet cooling and heating demands of users, the cost for replacement of antifreezing liquid is reduced, meanwhile, the heat tapes do not need to be driven by excessive electric energy, the purposeof energy saving is achieved, the cost is reduced, the service life is prolonged, and the cooling and heating system has good practicability.

Owner:银川雷升太阳能有限公司

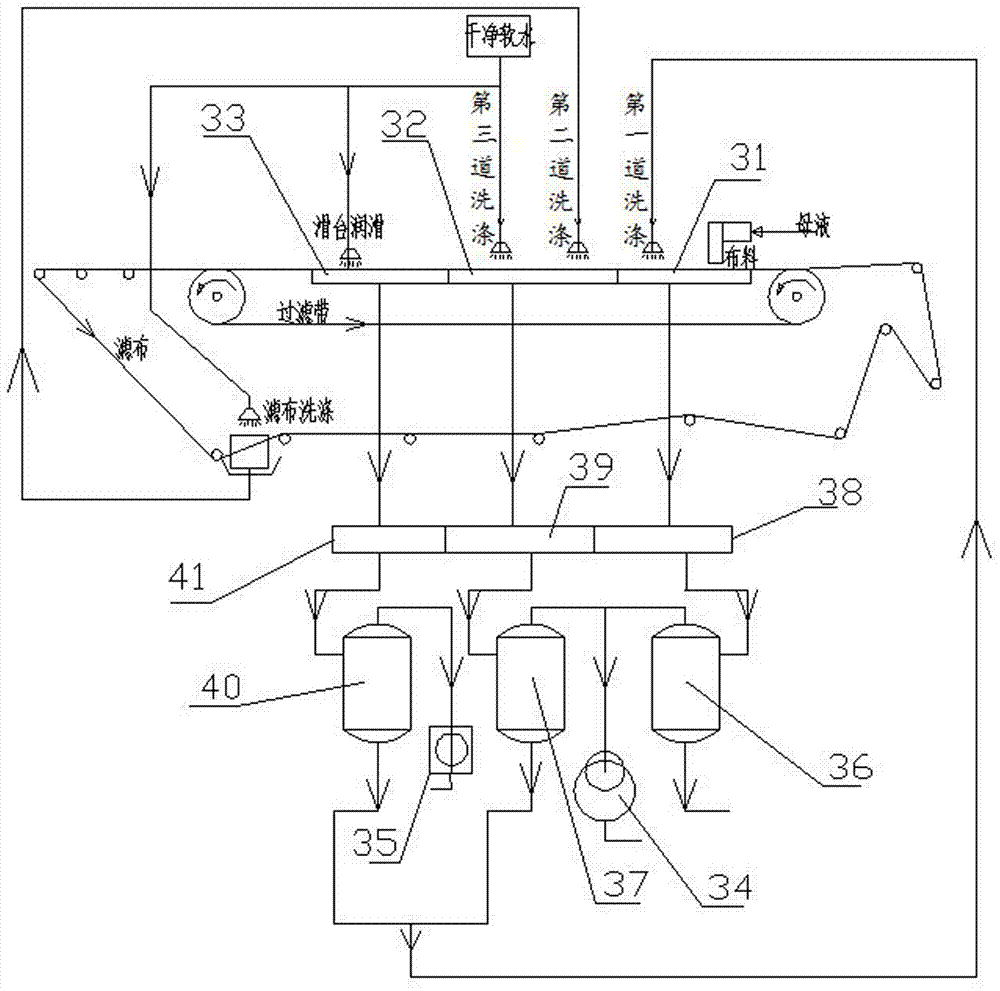

Alkali filtering process of vacuum alkali filtering machine

ActiveCN107117633ALow vacuum consumptionMembrane filtersAlkali metal carbonatesWater filterProcess engineering

The invention provides an alkali filtering process of a vacuum alkali filtering machine. The alkali filtering process of the vacuum alkali filtering machine comprises three areas, including a water filtering area, a washing area and a drying area which are arranged on the alkali filtering machine; a vacuum area of equipment is a segmented vacuum area; the water filtering area and the washing area adopt one same vacuum area; the drying area is an independent vacuum area; the water filtering area and the washing area adopt a water-ring vacuum pump as a negative pressure source, and the negative pressure value is 0.045 to 0.07 MPa; the drying area adopts a vacuum machine as a negative pressure source, and the negative pressure value is 0.045 to 0.05 MPa. According to the alkali filtering process of the vacuum alkali filtering machine, the vacuum consumption is low, the vacuum equivalent is reduced from original 630 m<3> / T to 460 m<3> / T, and the energy consumption is low; the moisture of a filtered material is reduced, and the moisture is reduced from original 17 percent to 15 percent; the filtering loss is reduced, and the filtering loss is reduced from original 1.85 percent to 1.7 percent; the washing water equivalent is reduced, and the washing water equivalent is reduced from original 0.67 m<3> / T to 0.57 m<3> / T.

Owner:WEIFANG XINSHAN ENVIRONMENTAL PROTECTION HEAVY IND TECH

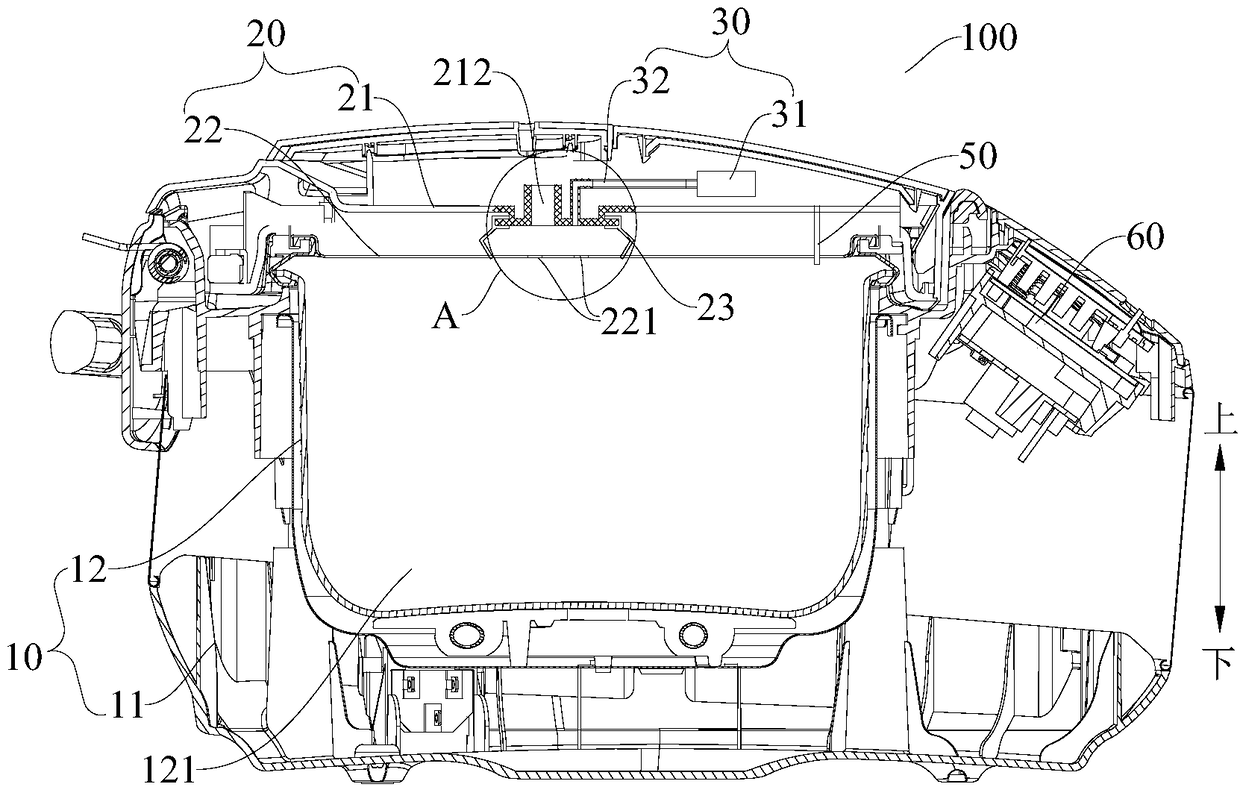

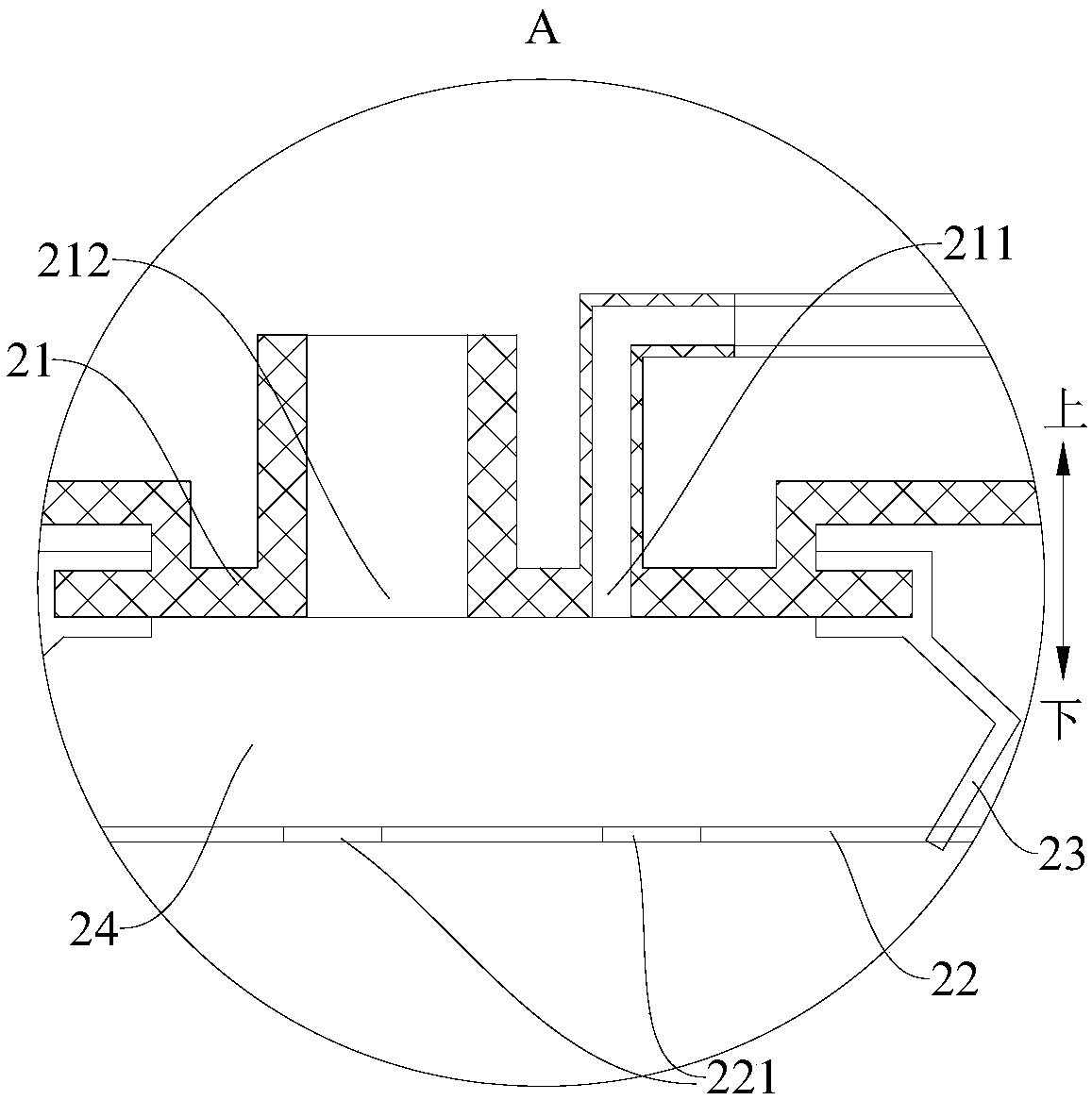

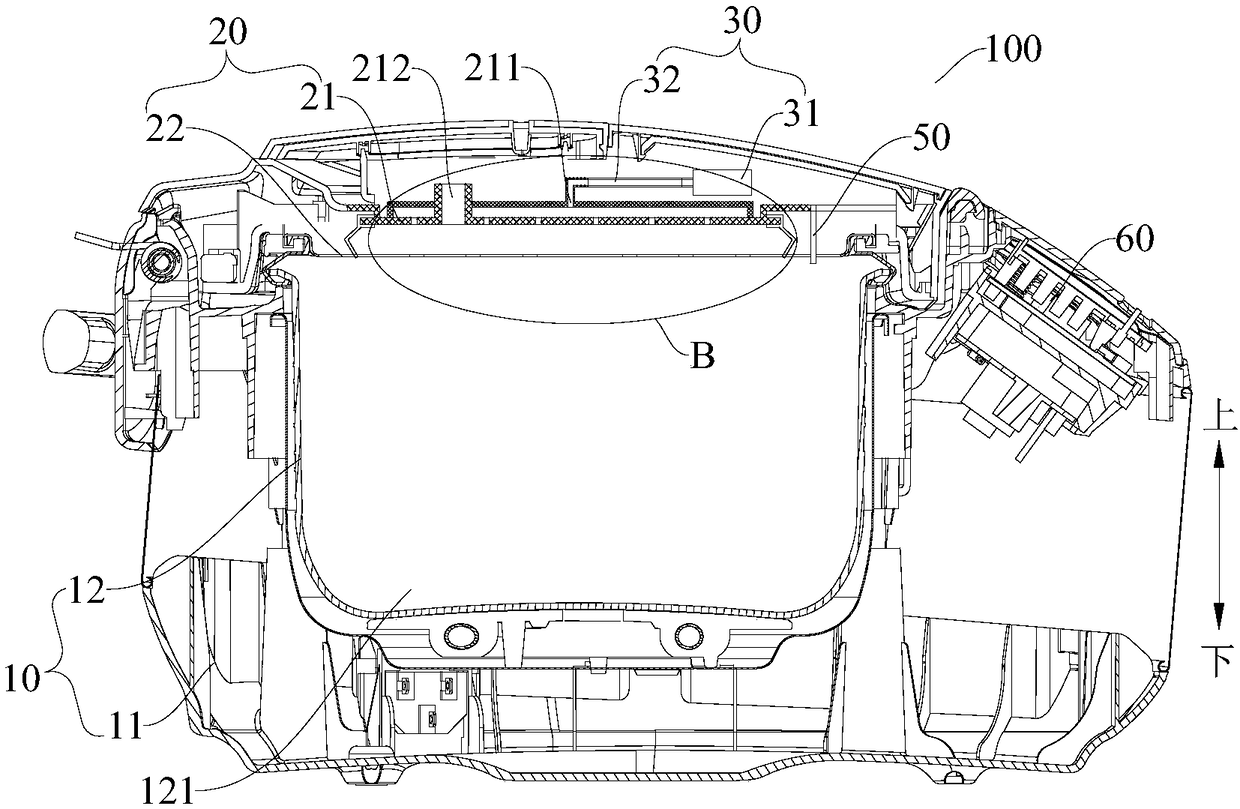

Cooking appliance and anti-overflow control method thereof

ActiveCN109452861ANutrient lossRapid bubble breakBoiling over preventionCooking-vessel lids/coversEngineeringDevices vacuum

The invention discloses a cooking appliance and anti-overflow control method thereof. The cooking appliance comprises a pot body and a cover body. The cover body comprises an inner cover and a cover plate, wherein the inner cover is provided with at least one negative pressure hole, and the cover plate is disposed on the side of the inner cover facing a cooking chamber and a plurality of airflow through holes. The vacuum device is arranged corresponding to the inner cover, and is connected with at least one negative pressure hole, and the vacuum device vacuums the cooking chamber to form a negative pressure bubble burst area between the inner cover and the cover plate. When the cooking appliance enters the boiling stage, a control module is used for controlling the vacuum device to make the bubbles generated in the cooking chamber burst when contacting the negative pressure bubble burst area. According to the cooking appliance and anti-overflow control method thereof, when the cookingappliance enters the boiling stage, the control module controls the startup and shutdown of the vacuum device so that bubbles generated in the cooking chamber are burst when contacting a negative pressure bubble burst area, so that rapid, large-area bubble burst is realized, and the anti-overflow effect is greatly improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

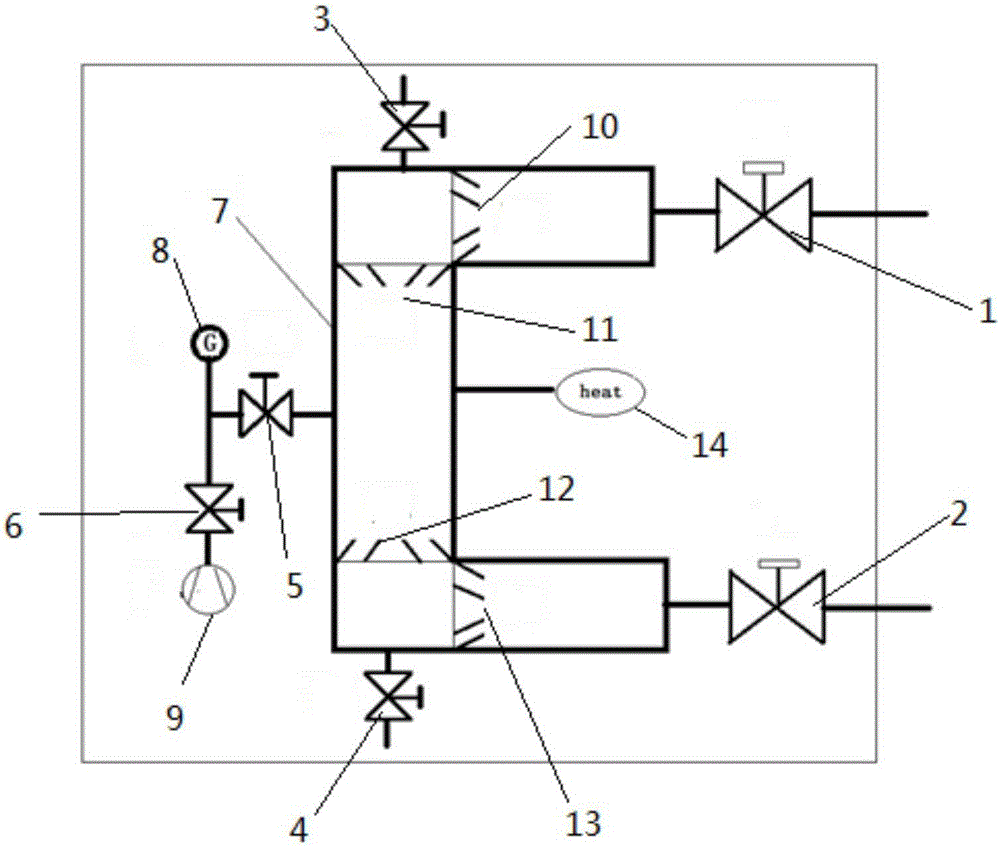

Energy-saving control method for cascade type heat pump vacuum freeze drying combination equipment

The invention relates to an energy-saving control method for cascade type heat pump vacuum freeze drying combination equipment. The energy-saving control method for a control system is characterized by comprising the steps that the temperature T1 of a heating medium entering a heating partition plate of a drying chamber is determined according to food drying technological requirements; according to the vacuum degree requirements of the combination equipment and thickness changes of the frost layer on the surface of a water catcher in the combination equipment operation process, the functional expression of the evaporation temperature T5, changing along with operation time t, of the water catcher in the combination equipment operation process is determined; according to the evaporation temperature T5 of a low-pressure stage refrigeration system water catcher and the condensation temperature T2 of a high-pressure stage condenser, the high-pressure stage evaporation temperature T3 of a condensation evaporator and the functional expression of the high-pressure stage evaporation temperature T3 changing along with the evaporation temperature T5 and the condensation temperature T2 are determined; according to the functional expression of the evaporation temperature T5, changing along the operation time t, of the water catcher, the determined high-pressure stage evaporation temperature T3 is calculated, and energy saving is achieved by adjusting the opening degree of a high-pressure stage throttling valve and adjusting the rotating speed of a high-pressure stage compressor. The method has the advantages that the evaporation temperature of the low-pressure stage water catcher can be dynamically adjusted according to the thickness changes of the frost on the surface of the water catcher, energy-saving operation of the cascade type refrigeration system is achieved, and more energy is saved in the operation process.

Owner:SHUNDE POLYTECHNIC

Regenerative type lithium steam filtration system of lithiation wall treatment gas pumping system

ActiveCN106582119AProtectReduce the impactDispersed particle separationVacuum evaporation coatingCooking & bakingLithium

The invention discloses a regenerative type lithium steam filtration system of a lithiation wall treatment gas pumping system. The regenerative type lithium steam filtration system of the lithiation wall treatment gas pumping system is installed between an EAST lithiation wall treatment gas pumping molecular pump and an EAST device vacuum chamber; in the EAST lithiation wall treatment period, when passing through the filtration system, gas containing lithium steam and other particles can sequentially collide with four umbrella-shaped baffle systems to be adsorbed on the umbrella-shaped baffle systems, and therefore the probability that these harmful gas molecules reach the molecular pump is reduced, and protection on the molecular pump can be achieved; and after being used for a period of time, the filtration system can perform washing, baking and gas pumping operation to be regenerated by means of its regenerative system, so that lithium coatings and other harmful substances attached to the baffle systems and pipeline device walls can be removed, and subsequent continuing use is facilitated. The successful development of the system can reduce influences of lithium steam and other harmful gas molecules on the molecular pump to the maximum extent in the EAST lithiation process.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Energy-saving control method for jet enthalpy gain heat pump vacuum freeze drying unit equipment with economizer

The invention relates to an energy-saving control method for jet enthalpy gain heat pump vacuum freeze drying unit equipment with an economizer. The energy-saving control method for a control system is characterized by comprising the following steps of according to requirements of a food drying process, determining the temperature T1 of heating mediums entering an inlet of a heating partition board of a drying chamber; according to vacuum requirements of the unit equipment and the changes of the thickness of a surface frost layer of a water catcher in the operation process of the unit equipment, determining a functional expression of changes of evaporating temperature T3 of the water catcher in the running process of the unit equipment along with running time t; according to the functional expression of the changes of the evaporating temperature T3 of the water catcher along with the running time t, realizing energy-saving control through the opening degree of a main throttle valve, and speed adjustment of a jet enthalpy gain frequency conversion compressor; according to the evaporating temperature T3 of the water catcher and condensing temperature T2 of a condenser, obtaining the best opening degree of an auxiliary throttle valve corresponding to the main throttle valve under different opening degrees through experiment or theoretical arithmetic, and adjusting the opening degree of the auxiliary throttle valve, so that a refrigerating system is in the best energy efficiency ratio of the refrigerating system. The energy-saving control method disclosed by the invention has the advantages that the evaporating temperature of the water catcher can be dynamically adjusted according to the changes of the frosting thickness of the water catcher, energy-saving running of the jet enthalpy gain refrigerating system with the economizer is realized, and the refrigerating system runs in the energy-saving manner.

Owner:SHUNDE POLYTECHNIC

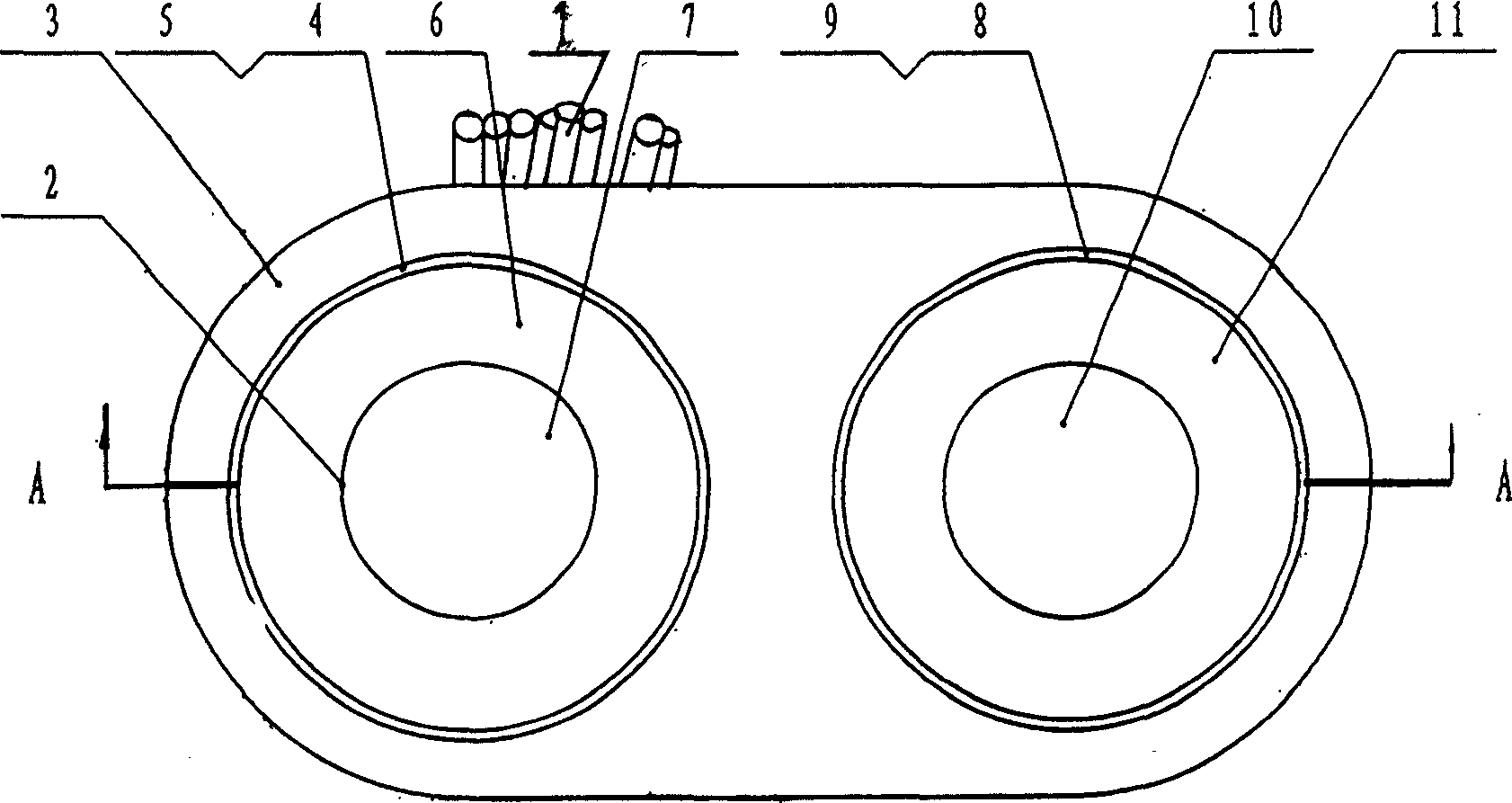

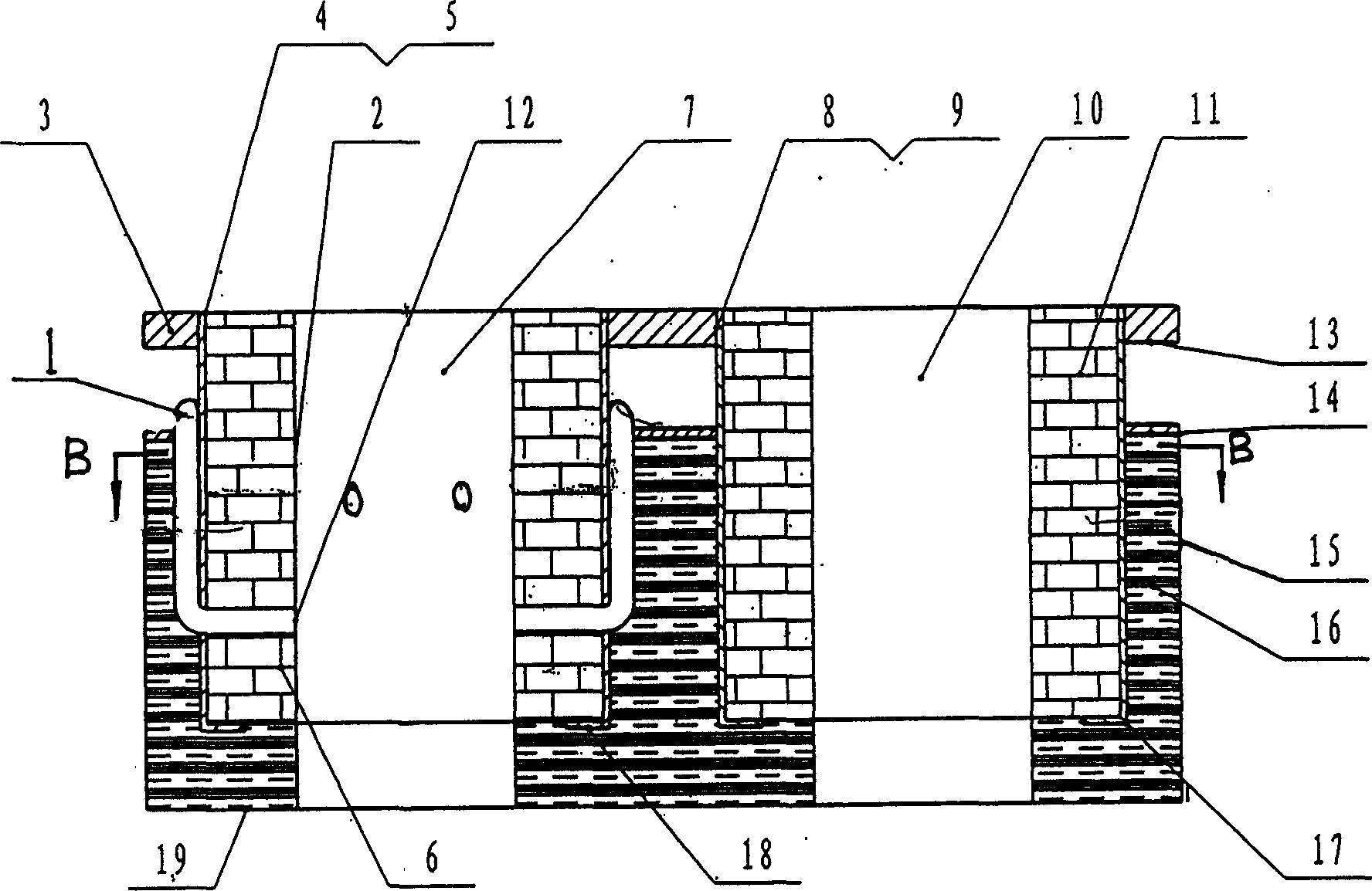

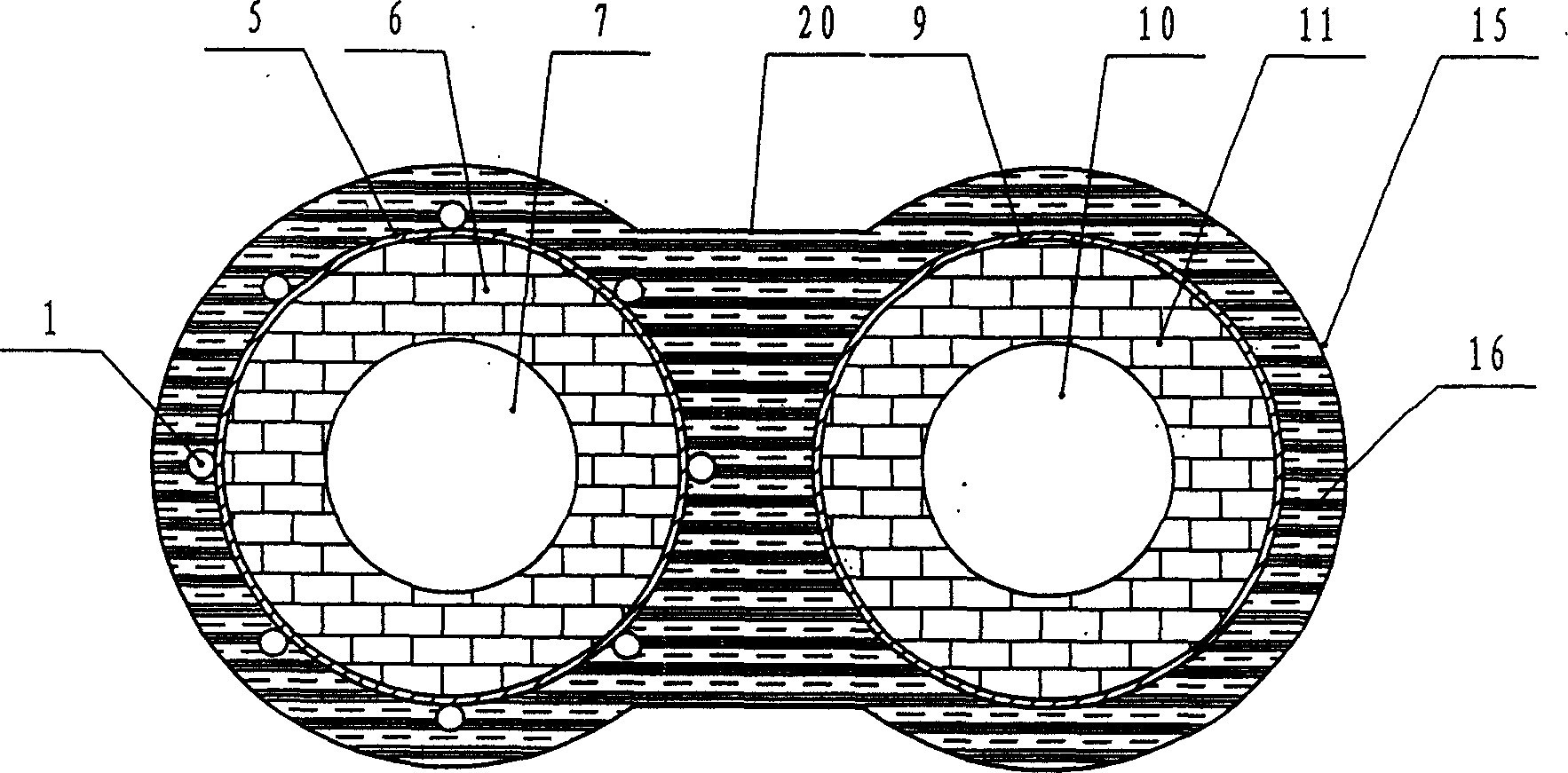

Insert tube of vacuum circulating degasification apparatus

InactiveCN1730675AIncrease steel productionIncrease productionProcess efficiency improvementBrickArchitectural engineering

Disclosed is an insert tube of vacuum circulating degasification apparatus which comprises a coupling flange, a steel cylinder, a refractory brick layer and a fire proof cement sheath, wherein the coupling flange is provided with two apertures, the distance between the centers of the two apertures corresponds or is equal to the centers of the two coupling ports below the vacuum chamber of the vacuum recycled degasification equipment, each of the two apertures is connected with a steel cylinder through soldering, one of the steel cylinders is provided with 6-12 non-corrodible steel vent pipes around the through-holes of the refractory brick layer for letting in argon gas.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

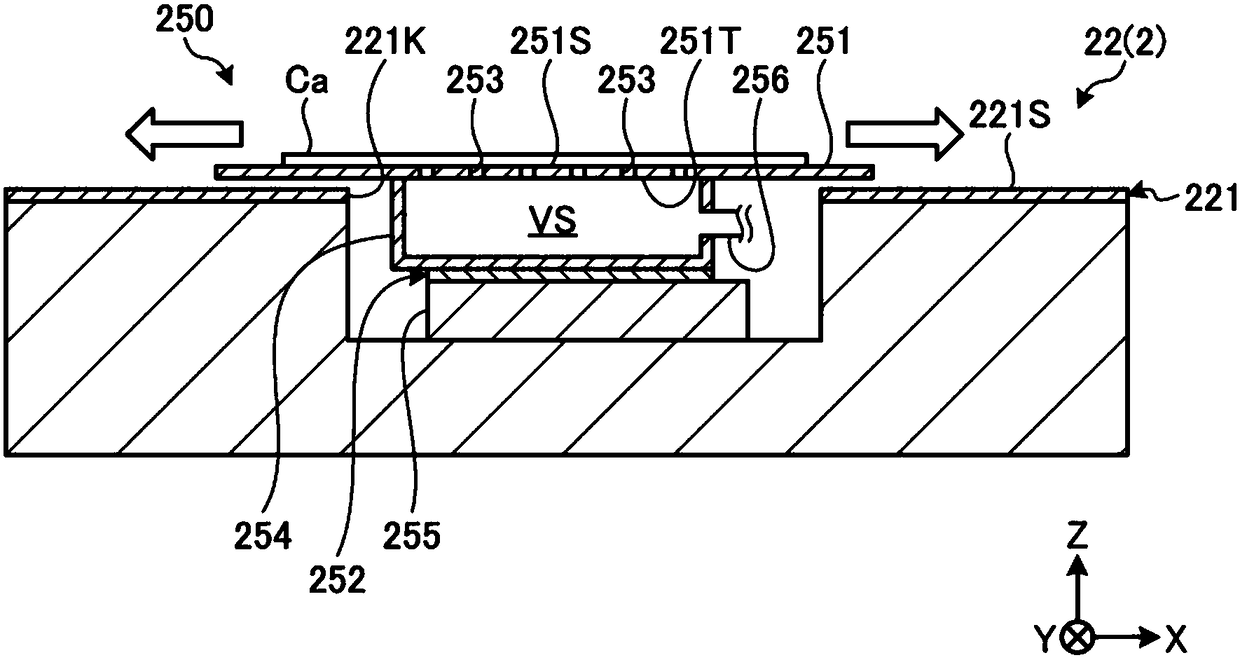

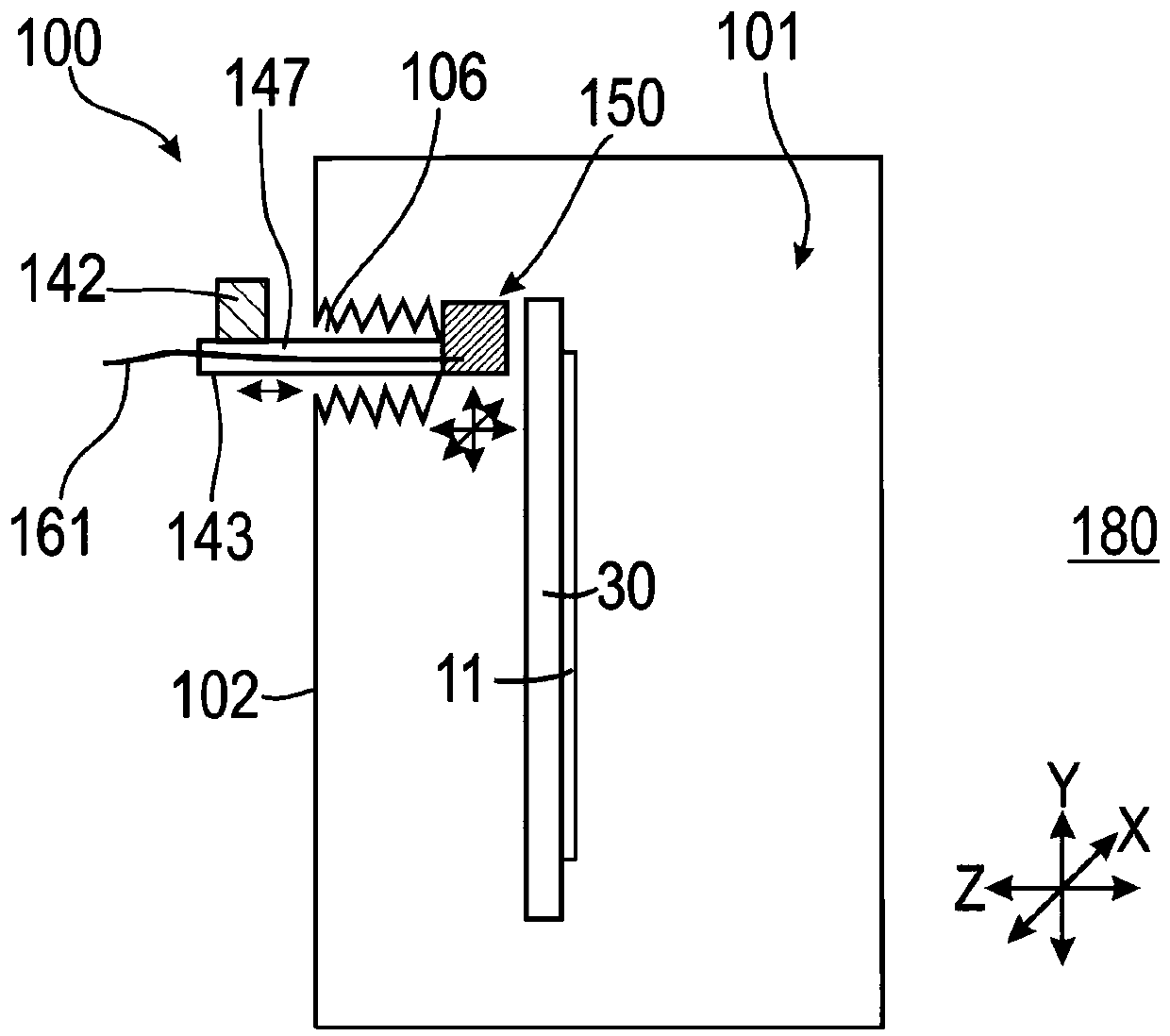

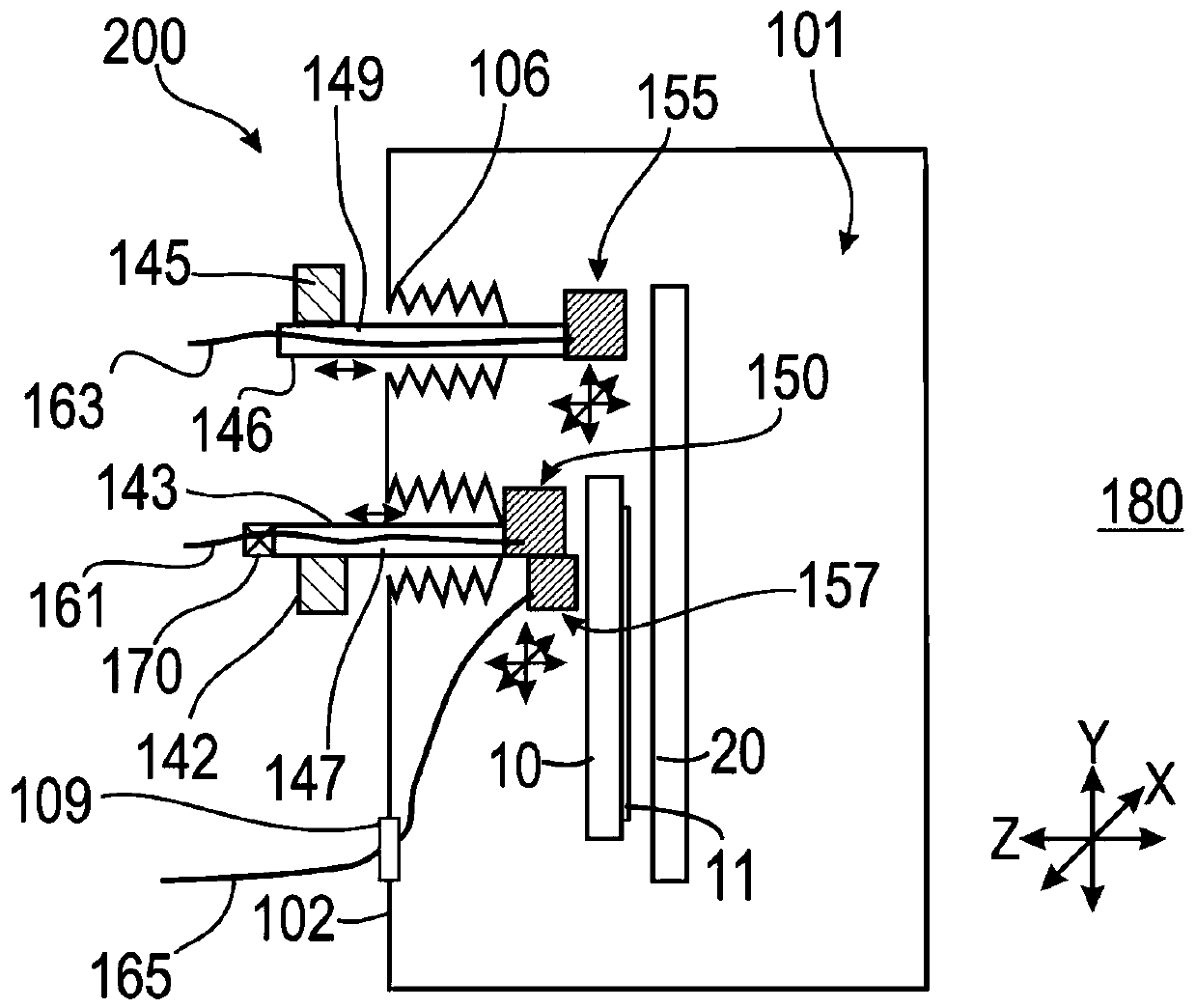

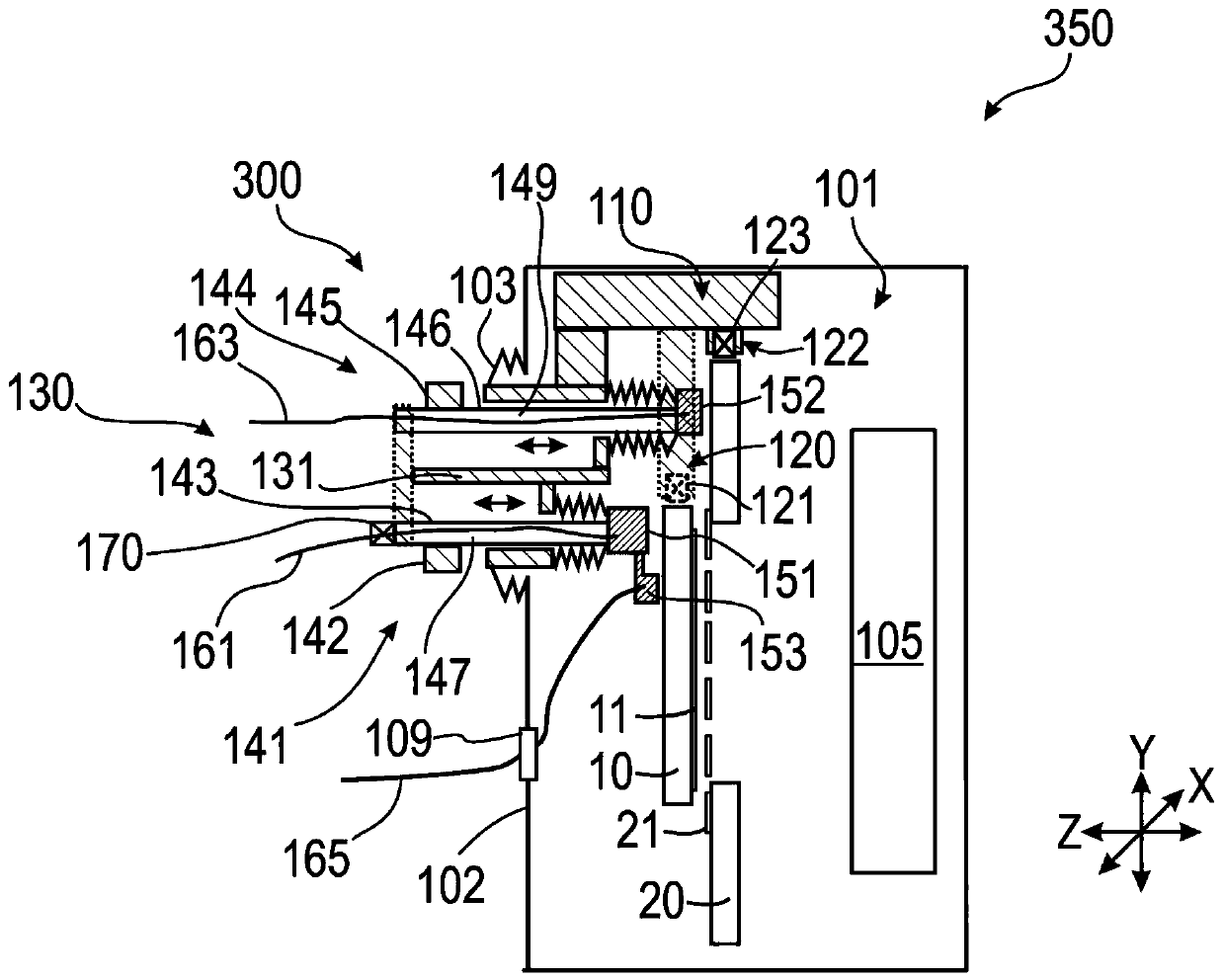

Apparatus for handling a carrier in a vacuum chamber, vacuum deposition system, and method of handling a carrier in a vacuum chamber

InactiveCN110557952AVacuum evaporation coatingSemiconductor/solid-state device manufacturingMechanical engineeringVacuum chamber

An apparatus (100) for handling a carrier in a vacuum chamber is described. The apparatus (100) includes a vacuum chamber (101) having a wall (102) with an opening (106). A first driving unit (142) isarranged outside the vacuum chamber (101) and configured to move a first driven part (143) extending through the opening (106) into the vacuum chamber (101). A first component (150) for holding or moving a carrier (30) is attached to the first driven part (143) in the vacuum chamber (101). The first driven part (143) provides a first supply passage (147) for supplying the first component (150). Further, a vacuum deposition system and a method of handling a carrier are described.

Owner:APPLIED MATERIALS INC

Transfer and positioning device and method for pole pieces of wound laminated batteries

ActiveCN105870512BPrecise positioningNo dimensional deviationFinal product manufactureElectrolyte accumulators manufactureLongitudinal planeEngineering

The invention relates to a transfer positioning device and a transfer positioning method for winding-type laminated battery pole pieces. There is an adsorption device for adsorbing and fixing the battery pole pieces to be processed. The transfer and positioning device for pole pieces of wound laminated batteries, the adsorption device and the heat compound device are not in the same longitudinal plane. The vacuum suction cup, which is an adsorption device for absorbing and fixing the battery pole pieces to be processed, is provided above the conveying device, so that during the semi-hot pressing process through the semi-hot pressing device, the battery pole pieces and the diaphragm are positioned accurately, and the pole pieces will not move. If there is a size deviation, the involved laminated battery can be directly wound after the hot-compression lamination is completed, which can greatly improve the production efficiency.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Variable capacitance measuring device

InactiveUS20050039535A1Reliable and compact deviceReduce width sizeFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsThermal expansionHeat losses

A variable capacitance measuring device can comprise any one or more features in various different embodiments allow a reliable, compact device to be achieved. A capacitor electrode, a gettering housing, and pinch-off connector may be aligned along a common axis may reduce width dimensions without a substantial increase in length. Temperature-induced variations may be reduced by selecting materials that have coefficients of thermal expansion relatively closer to one another. Substantially varying topologies for ceramic-metal interfaces may reduce the likelihood of external contaminants from reaching the evacuated portion of the device. A tube can be used between the capacitor portion and a gettering housing to isolate external forces and getter activation heat from the sensor. The same tube also reduces heat loss from a heated sensor and protects the electronics from overheating. Embodiments also include processes for using and forming the devices.

Owner:BROOKS INSTRUMENT +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com