Vacuum casting device

A technology of vacuum casting and cooling device, applied in the field of vacuum casting device, can solve the problems of inefficient recovery and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

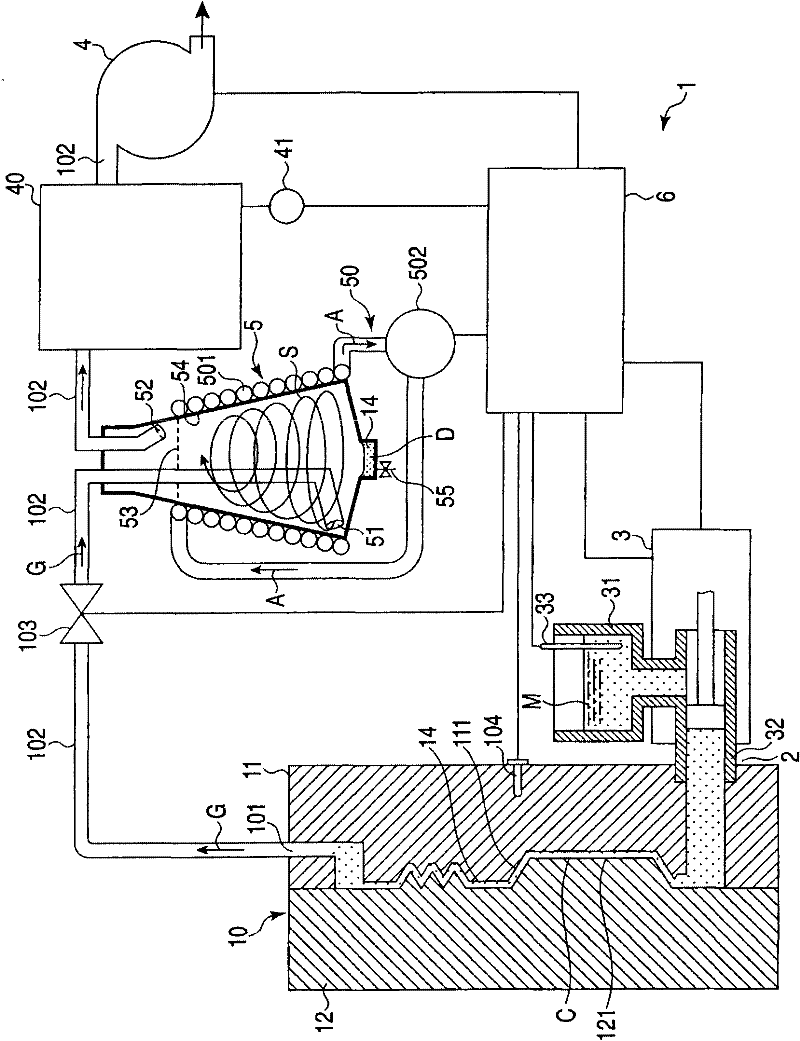

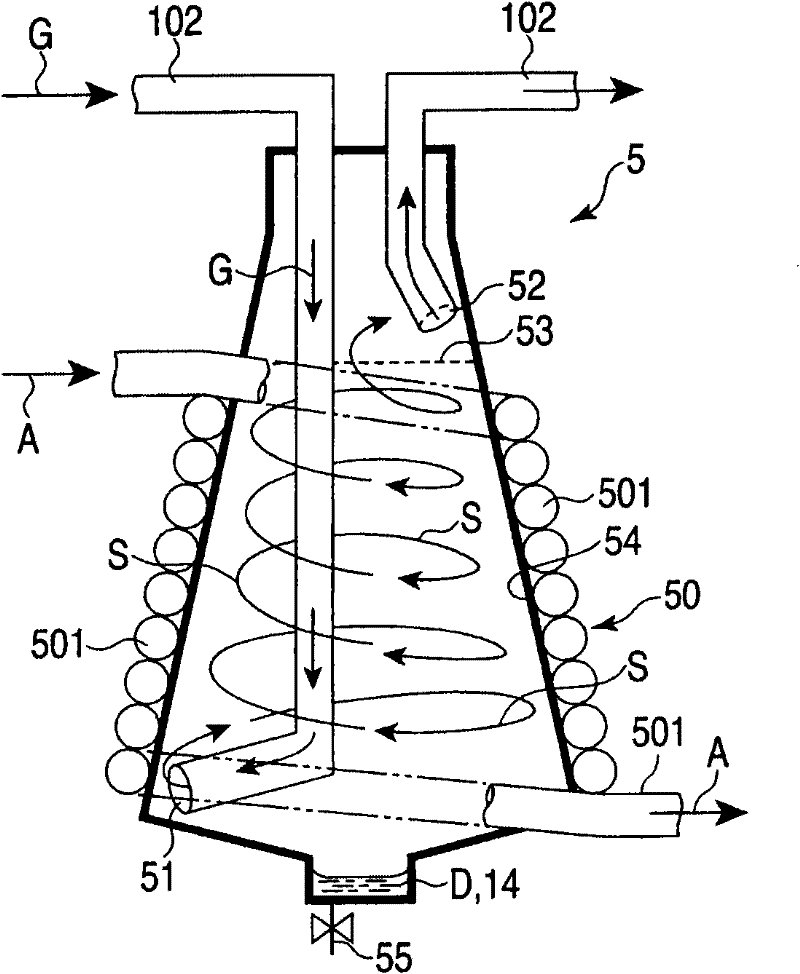

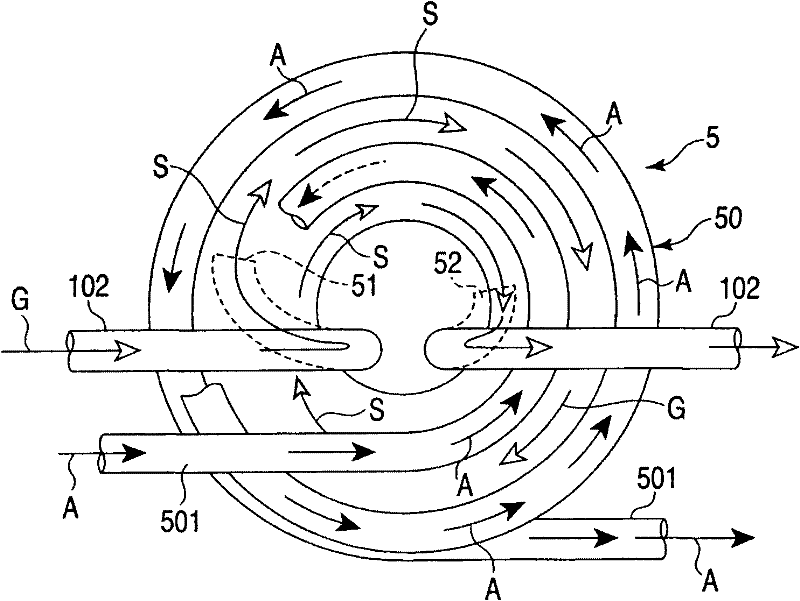

[0012] refer to Figure 1 to Figure 3 The vacuum casting device of the first embodiment will be described. figure 1 The shown vacuum casting device 1 has a mold 10, a plunger 3, a molten metal tank (molten metal tank) 31, a suction pipe 102, a valve (valve) 103, a vacuum pump 4, a vacuum tank 40, a release agent recovery machine 5, a cooling device 50, and control device 6. The mold 10 is divided into a first mold 11 and a second mold 12 along the dividing line of the product. The first mold 11 and the second mold 12 have a first parting surface 111 and a second parting surface 121 at joint surfaces. The first parting surface 111 and the second parting surface 121 form a cavity C for casting a product by joining the first mold 11 and the second mold 12 together. A release agent 14 is coated on the inner surface of the cavity C. The mold 10 has a melt supply port 2 communicating with the cavity C and a suction port 101 .

[0013] Such as figure 1 As shown, the plunger 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com