Regenerative type lithium steam filtration system of lithiation wall treatment gas pumping system

A technology of filtering system and air extraction system, applied in vacuum evaporation coating, chemical instruments and methods, ion implantation coating, etc., can solve the problems of breaking molecular pumps, weakening the flexibility of bearing operation, and increasing the operating burden of molecular pumps, etc. , to achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

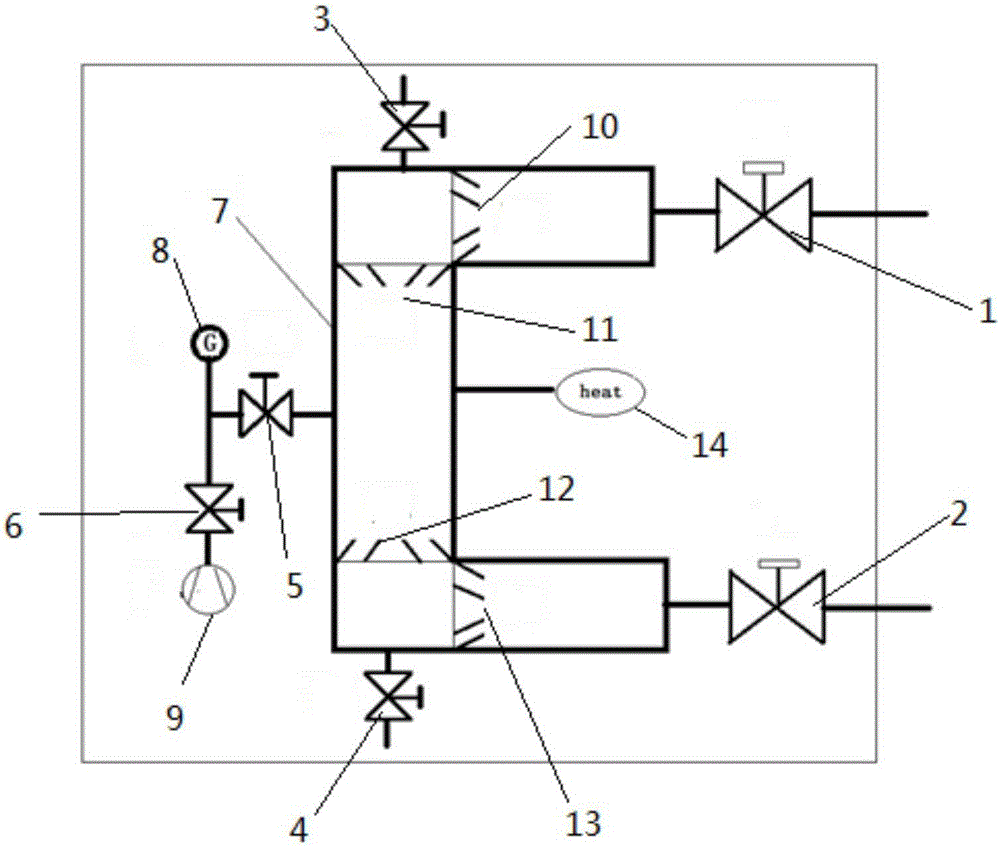

[0012] Such as figure 1 As shown, a regenerative lithium vapor filter system of a lithiated wall treatment exhaust system includes an inlet valve 1, an outlet valve 2, a regeneration system, a baffle system, a measuring gauge 8 and a cavity 7, the The air inlet valve 1 and the air outlet valve 2 are respectively connected to the two ends of the cavity 7, and the baffle system is composed of four sets of filter systems in series, and the four sets of filter systems in series are installed in the cavity 7 respectively. Four different positions, and placed in sequence front and back, the regeneration system includes a water flow flushing system, a heating belt baking system 14 and a vacuum pumping unit 9, the water flow flushing system includes a water inlet valve 3 and a water outlet valve 4, The water inlet valve 3 and the water outlet valve 4 are respectively connected to the cavity 7, the water inlet valve 3 is connected between the first and second filter systems 10, 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com