Alkali filtering process of vacuum alkali filtering machine

An alkali filter and vacuum technology, which is applied in mobile filter element filters, inorganic chemistry, filtration and separation, etc., can solve problems such as failure to perform, high moisture content of filtration materials, and large water consumption for washing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

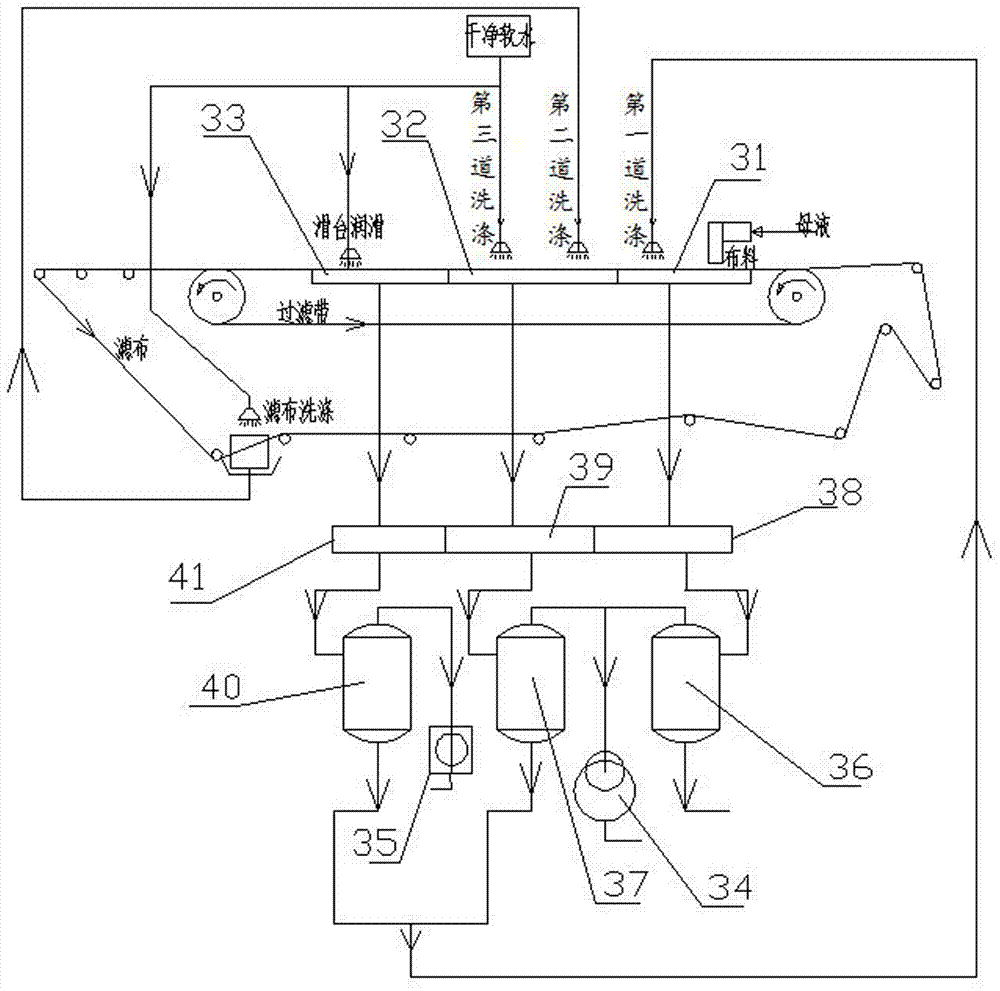

[0027] For the convenience of explanation, below in conjunction with accompanying drawing, the caustic soda filtering process of the invented vacuum caustic soda filter is described in detail.

[0028] Such as figure 1 As shown in , a vacuum belt alkali filter alkali filtration process:

[0029] The caustic filtering process includes using three areas arranged on the caustic filtering machine: a water filtering area, a washing area and a drying area.

[0030] The vacuum area of the equipment is a segmented vacuum, the water filtration area and the drying area adopt the same vacuum area, and the drying area is a separate vacuum area.

[0031] Water ring vacuum pumps with high negative pressure and small air volume are used as negative pressure sources in the water filtration area and washing area, and the general negative pressure value is -0.045 to -0.07MPa.

[0032] The water ring vacuum pump is respectively connected with the first gas-liquid separation tank and the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com