Flow rotary production device for single blood sampling pipes

A production device and technology of blood collection tubes, which is applied in the field of single flowing water rotary production device of blood collection tubes, can solve the problems of not being able to process only one piece of flow water, large consumption of blood collection tubes, difficulty in single test tube, etc., and achieves easy supervision and control, and high degree of automation , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

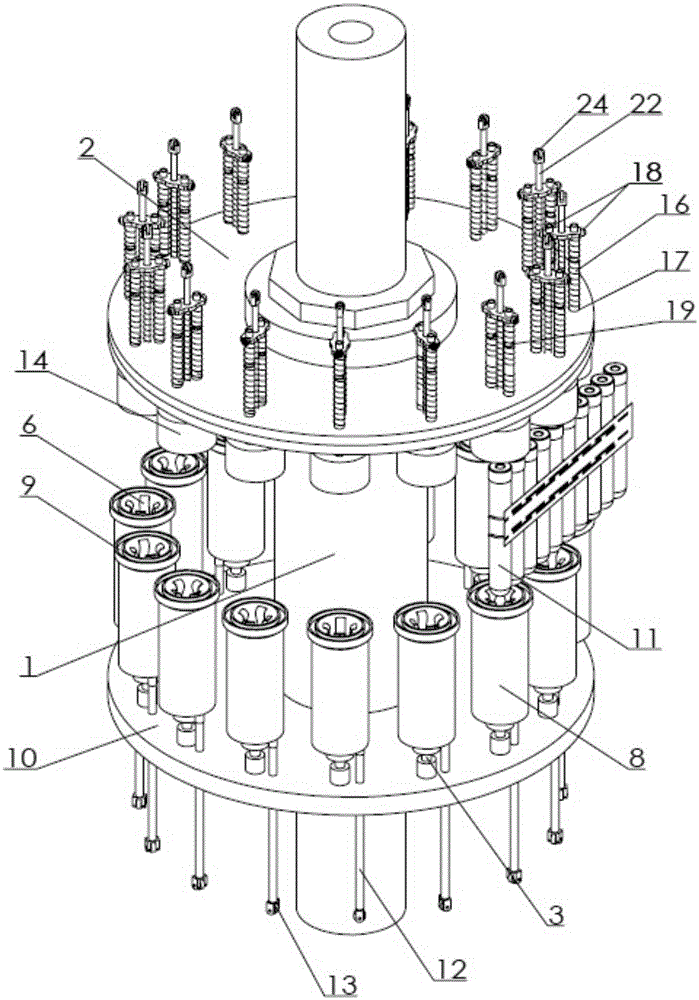

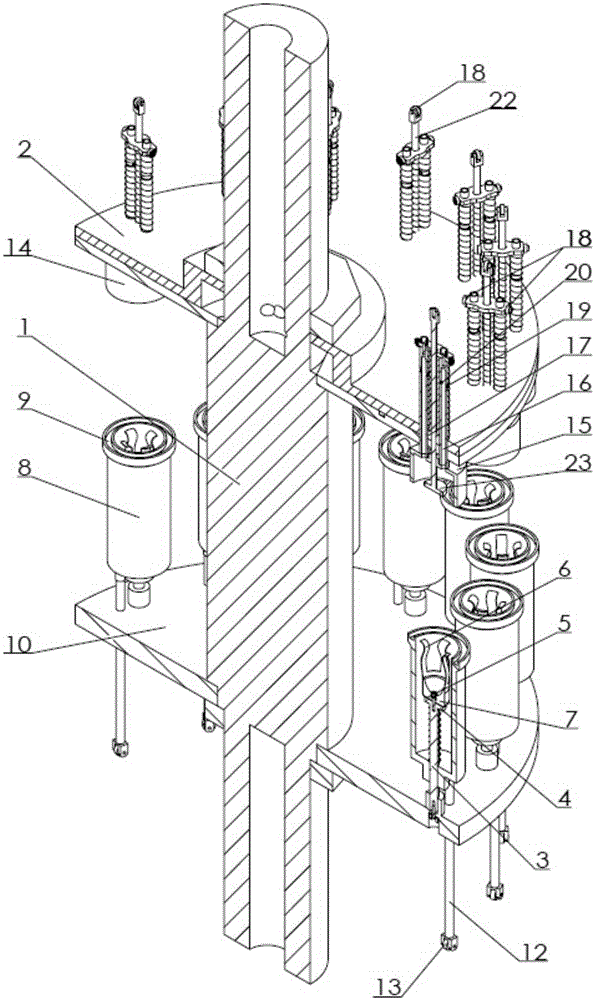

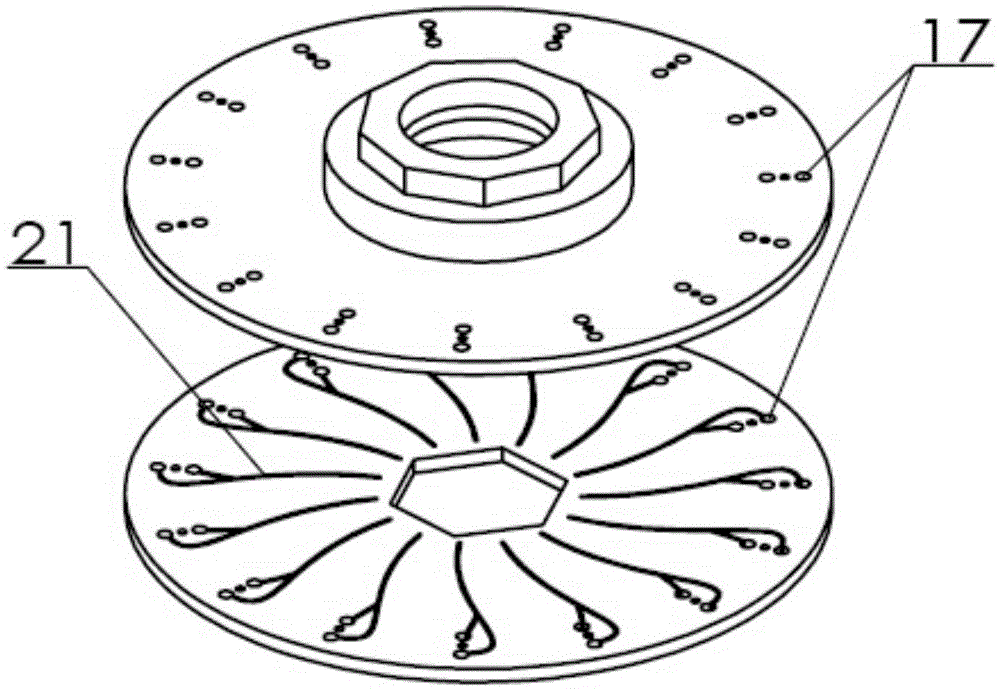

[0014] Examples of the present invention Figures 1 to 4 As shown, the single flowing water rotary production device for blood collection tubes includes a vertical shaft 1 with laterally protruding shoulders in the middle, and an upper turntable 2 and a lower turntable 10 that rotate synchronously are fixedly connected to the vertical shafts at both ends of the shoulders. ; The lower turntable is distributed with upright columns 3 in the upper direction, and the upper end of the column is provided with a boss 4, and a disc 5 is connected to the boss, and a shrapnel 6 for clamping the side wall of the blood collection tube 11 is connected around the disc. Clamp and straighten the blood collection tube, the upper part of the disc is connected with a rubber pad 7, the upper surface of the rubber pad is provided with a depression that coincides with the bottom of the blood collection tube, a lower sleeve 8 is provided outside the column, and the lower end of the lower sleeve is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com