Vacuum degree on-line detecting system

A detection system and technology of vacuum degree, which is applied to the online detection system of vacuum degree and the field of online detection of all vacuum tubes or vacuum containers in the station. It can prevent problems such as early warning, alarm, and hidden dangers in advance, so as to achieve the effect of preventing hidden dangers, reducing the vacuum leakage rate and accident rate, and ensuring the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

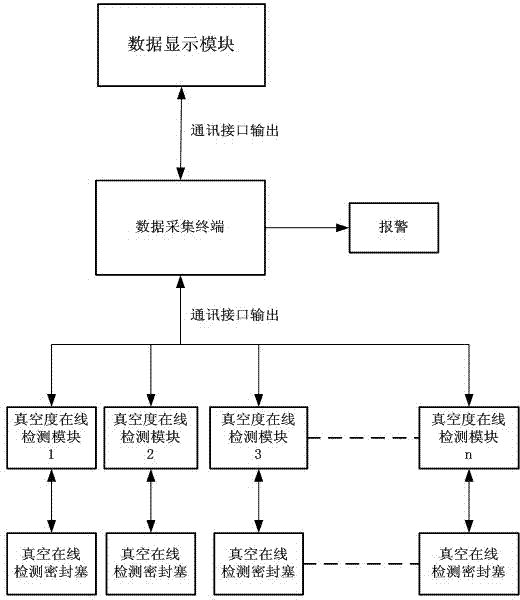

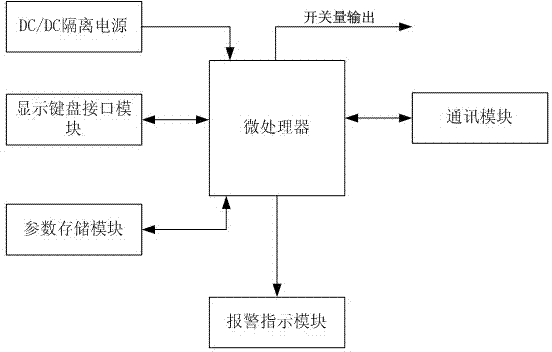

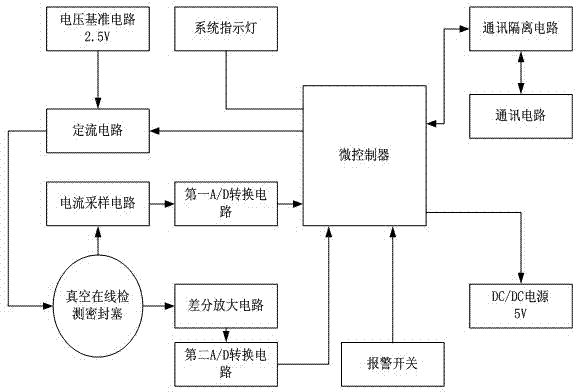

[0023] like figure 1 As shown, the vacuum online detection system of the present invention includes a data display module, a data collection terminal, a vacuum online detection module, and a vacuum online detection sealing plug; the data display module is connected to the data collection terminal, and the data collection terminal is connected to At least one vacuum degree online detection module (1-n), the vacuum degree online detection module is connected to the vacuum online detection sealing plug; wherein, the vacuum online detection sealing plug is used to obtain vacuum data in the vacuum equipment; the vacuum degree The online detection module is used to process the vacuum data obtained by the vacuum online detection sealing plug to obtain the vacuum degree of the vacuum layer of the vacuum equipment; the data acquisition terminal is used to obtain the vacuum degree data sent by at least one vacuum degree online detection module, and according to The comparison result of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com