a vacuum glass

A vacuum glass and glass technology, which is applied in the field of glass deep processing, can solve the problems of reducing the strength of the bottom glass, time-consuming and laborious processing, and shortening the service life, and achieves the effects of improving the compressive strength, low process cost, and improving the thermal insulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

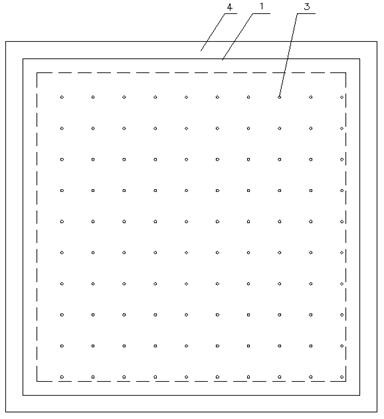

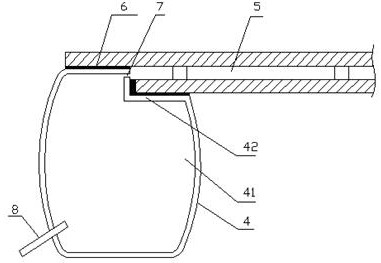

[0034] Such as Figure 1~Figure 3 Shown: a vacuum glass, including a first glass 1, a second glass 2 and a support 3 between the two layers of glass, the first glass 1 and the second glass 2 are surrounded by a frame 4, and the two layers of glass A vacuum cavity 5 is formed between them; the frame 4 , the support member 3 and the first glass 1 and the second glass 2 are connected by a sealant 6 .

[0035] Specifically, the frame 4 is provided with an inner cavity 41, and the inner cavity 41 of the frame 4 communicates with the vacuum chamber 5, so that a large vacuum space is formed between the two layers of glass. Both ends of the frame 4 are connected with the vacuum glass through a sealant 6 . One end of the frame 4 is provided with a step 42, and the second glass 2 is embedded in the step, and the sealant 6 is applied between the step 42 and the second glass 2. Compared with applying an adhesive layer on a horizontal plane, the bonding strength and airtightness are bette...

Embodiment 2

[0048] Such as Figure 4 Shown: the difference with embodiment 1 is that the two ends of frame 4 ' are connected with vacuum glass by sealant 6. One end of the frame 4' is provided with a step 42', the second glass 2 is embedded in the step, and a sealant 6 is applied between the step 42' and the second glass 2, and the upper end of the step 42' is higher than a part of the upper surface of the second glass; The other end of the frame 4' is parallel to the side end of the first glass, and is higher than a part of the lower surface of the first glass, and a sealant 6 is applied between the other end of the frame 4' and the side end of the first glass 1, and the sealant 6 also covers the corners of the first glass.

[0049] Others are the same as embodiment 1.

Embodiment 3

[0051] Such as Figure 5 Shown: The difference from Example 1 is that the distance between the first glass 1 and the second glass 2 is 0.2mm, and the height of the inner cavity of the frame 4" is 100 times the distance between the first glass 1 and the second glass 2.

[0052] The support member 3" is made of stainless steel and has a hollow structure.

[0053] The space between the exhaust pipe 8 and the frame 4" is also sealed by a sealant.

[0054] The two ends of the frame 4" are connected with the vacuum glass through the sealant 6. One end of the frame 4" is provided with a step 42", the second glass 2 is embedded in the step, and the sealant 6 is applied between the step 42" and the second glass 2 The upper end of the step 42" is lower than the upper surface of the second glass 2; the other end of the frame 4" is parallel to the horizontal plane of the first glass 1, and a sealant 6 is applied between the lower surface of the first glass 1.

[0055] Others are the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com