Crystal growing furnace based on power descent method and crystal growing method

A technology of crystal growth furnace and power reduction, applied in crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problem that the growth furnace cannot meet the process requirements well, the heating uniformity of raw materials is deteriorated, and the heat loss of the heater Large and other problems, to achieve the effect of low total equipment cost, reduction of thermal energy loss, and simplified equipment manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

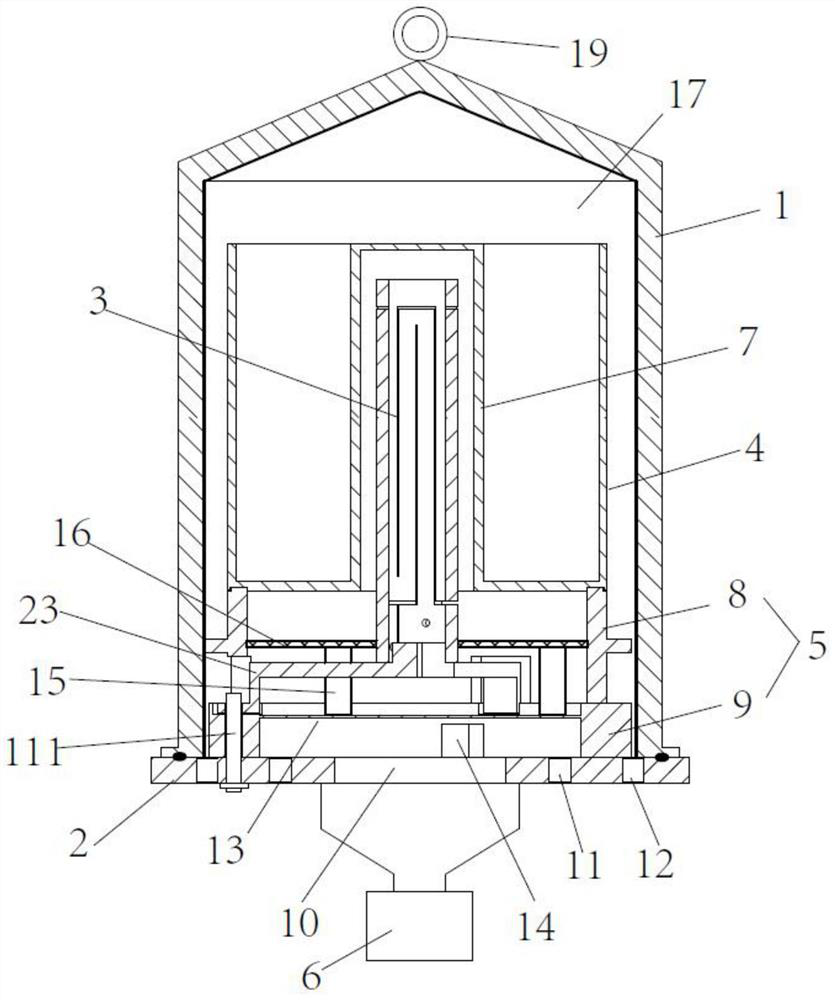

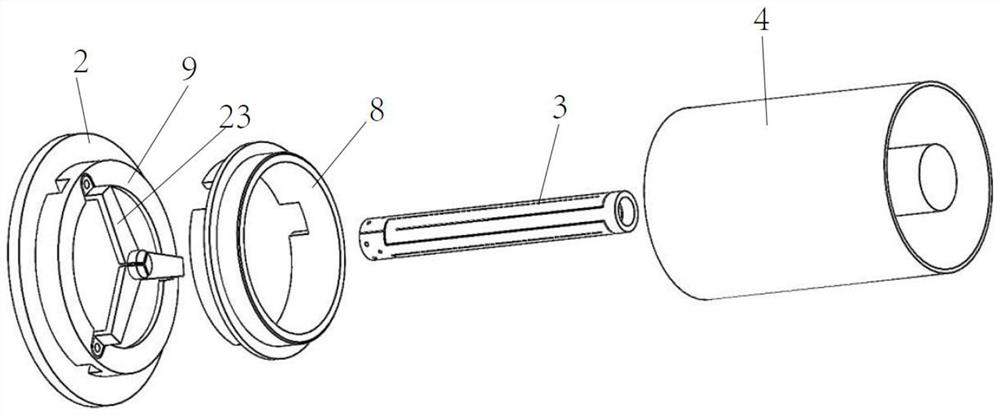

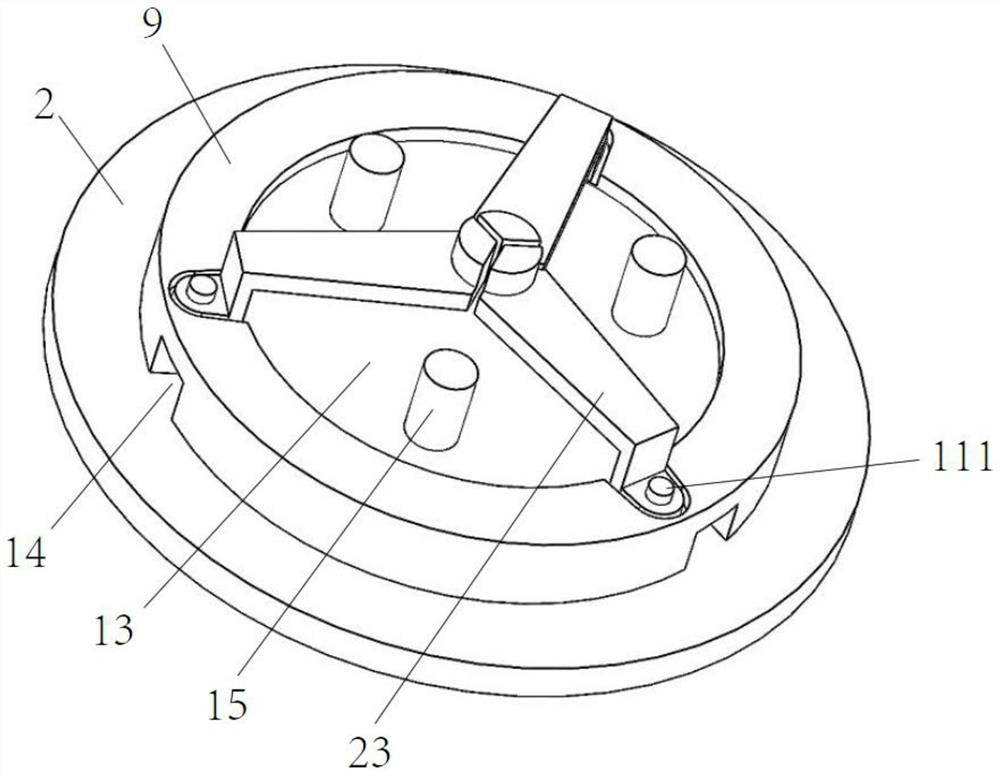

[0034] refer to Figure 1 to Figure 4 As shown, an embodiment of the crystal growth furnace based on the power drop method of the present invention includes a furnace body 1, a chassis 2 is arranged at the bottom of the furnace body, a heater 3 and a raw material crucible 4 are arranged in the furnace body, and the raw material crucible is arranged on the crucible base 5, the base of the crucible is set on the chassis, the chassis is connected to the vacuum device 6, the middle part of the raw material crucible is provided with an isolation sleeve 7, and the inside of the raw material crucible cooperates with the outer wall of the isolation sleeve to form a ring-shaped growth space...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com